lut . 03, 2025 02:55

Back to list

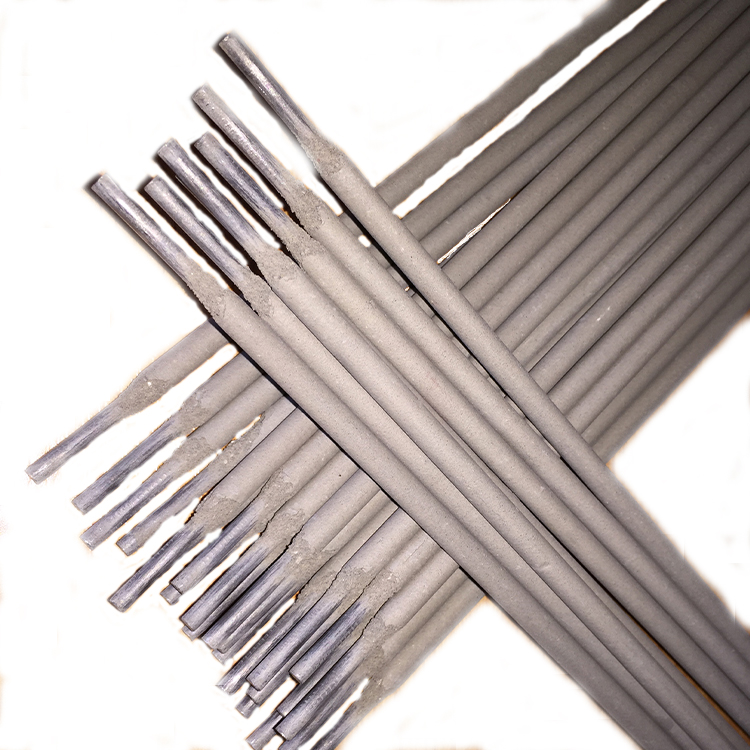

316l stainless steel welding rod

316L welding electrodes are a crucial component in the welding industry, especially when it comes to working with stainless steel. These electrodes have a unique composition that makes them ideal for a range of welding applications, offering both reliability and performance. With a primary focus on their usability, characteristics, and benefits, it's important to understand what makes 316L electrodes the go-to choice for many professionals.

Authoritativeness is another pillar upholding the reputation of 316L welding electrodes. Industry leaders and authorities recommend these electrodes for their consistent quality and effectiveness. They are engineered to meet stringent industry standards, which elevates their status as a benchmark for others. The material's exceptional heat resistance continues to make it a preferred option for sectors where precision and durability are non-negotiable. Trustworthiness in welding materials cannot be overstated. With 316L welding electrodes, you get what you expect – durable, reliable welds that stand the test of tough operational conditions. As a product trusted by professionals worldwide, these electrodes come from manufacturers who comply with global production standards, ensuring that every piece is of the highest quality. This provides peace of mind to welders who require products that do not compromise safety or performance. In product-focused environments, selecting the right welding electrode is critical. The performance of 316L welding electrodes in fabrication or repair projects stands as a testament to their versatility and robustness. Whether welding tanks, processing equipment, or structural parts exposed to corrosive environments, the electrodes provide a reliable outcome. In conclusion, 316L welding electrodes are an indispensable tool for those requiring superior weld quality, corrosion resistance, and ease of use. Their design and formulation cater to a wide array of applications, making them suitable for both ordinary and high-demand scenarios. They exemplify what industry standards should be, cementing their place as a trusted component in the welding world. As the welding landscape evolves, these electrodes continue to stand out, offering capabilities that meet the demands of modern industry needs.

Authoritativeness is another pillar upholding the reputation of 316L welding electrodes. Industry leaders and authorities recommend these electrodes for their consistent quality and effectiveness. They are engineered to meet stringent industry standards, which elevates their status as a benchmark for others. The material's exceptional heat resistance continues to make it a preferred option for sectors where precision and durability are non-negotiable. Trustworthiness in welding materials cannot be overstated. With 316L welding electrodes, you get what you expect – durable, reliable welds that stand the test of tough operational conditions. As a product trusted by professionals worldwide, these electrodes come from manufacturers who comply with global production standards, ensuring that every piece is of the highest quality. This provides peace of mind to welders who require products that do not compromise safety or performance. In product-focused environments, selecting the right welding electrode is critical. The performance of 316L welding electrodes in fabrication or repair projects stands as a testament to their versatility and robustness. Whether welding tanks, processing equipment, or structural parts exposed to corrosive environments, the electrodes provide a reliable outcome. In conclusion, 316L welding electrodes are an indispensable tool for those requiring superior weld quality, corrosion resistance, and ease of use. Their design and formulation cater to a wide array of applications, making them suitable for both ordinary and high-demand scenarios. They exemplify what industry standards should be, cementing their place as a trusted component in the welding world. As the welding landscape evolves, these electrodes continue to stand out, offering capabilities that meet the demands of modern industry needs.

Previous:

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025