china gas shield welding wire factory

China Gas Shield Welding Wire Factory Innovating the Future of Welding Solutions

In the realm of manufacturing, welding techniques play a crucial role in creating durable and robust structures. Among these, gas shielded welding has emerged as one of the most effective methods for joining metals. As industries across the globe strive for stronger bonds between components, the demand for high-quality welding materials, particularly gas shield welding wires, continues to rise. At the forefront of this market is China, where a multitude of factories are dedicated to producing superior gas shield welding wire.

China's gas shield welding wire factories have garnered a reputation for their advanced production techniques and commitment to quality. The nation's rapid industrialization has bolstered the demand for welding materials, particularly in sectors such as construction, automotive, shipbuilding, and aerospace. These factories utilize state-of-the-art technology, ensuring that their products meet international standards and can withstand the rigors of various applications.

China Gas Shield Welding Wire Factory Innovating the Future of Welding Solutions

Quality control is another crucial aspect of manufacturing gas shield welding wires in China. Many factories adhere to stringent quality management systems, such as ISO 9001 certification. This ensures that every batch of welding wire produced meets consistent standards of quality, strength, and performance. Furthermore, rigorous testing procedures are in place, where each product undergoes extensive evaluations, including mechanical testing and metallurgical analysis. By prioritizing quality, Chinese factories reassure their customers of the reliability and longevity of their welding wires.

china gas shield welding wire factory

Moreover, the cost-effectiveness of sourcing gas shield welding wires from China is an attractive proposition for businesses around the world. With competitive labor costs and advanced manufacturing processes, Chinese factories can produce high-quality welding materials at relatively lower prices than their counterparts in many Western countries. This economic advantage allows companies to maintain their profit margins while acquiring premium products that enhance their production capabilities.

Sustainability is also becoming an integral part of the manufacturing process in China. As environmental concerns gain prominence, several gas shield welding wire factories are adopting eco-friendly practices. This includes reducing emissions during the production process, recycling scrap materials, and using sustainable energy sources wherever possible. By focusing on green manufacturing, these factories not only appeal to environmentally conscious customers but also align themselves with global sustainability goals.

The rise of automation and digital transformation is another trend impacting the gas shield welding wire industry in China. Factories are increasingly incorporating advanced robotics and AI-driven technologies to optimize production processes. This not only enhances efficiency but also reduces the likelihood of human error, ensuring consistency in the quality of welding wires. Additionally, digital supply chain management systems allow for real-time tracking of materials, further streamlining operations.

In conclusion, the landscape of gas shield welding wire manufacturing in China is vibrant and continually evolving. With a commitment to quality, innovation, and sustainability, Chinese factories are setting new standards in the welding industry. As global demand for reliable welding solutions grows, these manufacturers are well-positioned to meet the challenges ahead. By investing in advanced technologies and maintaining strict quality control, China not only reinforces its role as a leader in manufacturing but also contributes to the overall advancement of welding techniques worldwide. As industries look toward the future, the importance of high-quality, reliable welding materials cannot be overstated, and China’s gas shield welding wire factories stand ready to meet this need head-on.

-

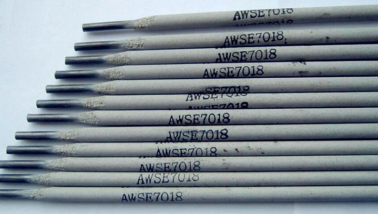

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025