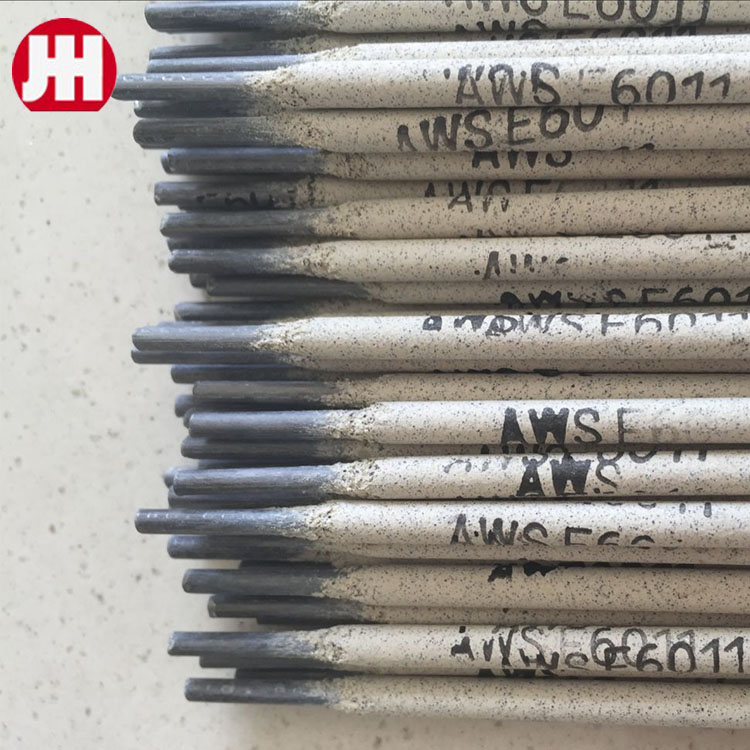

E6011 Welding Rod | All-Position AC/DC Electrodes

Discover the e6011 welding rod and its cutting-edge manufacturing processes, technical benchmarks, application expertise, and in-depth product comparisons. This guide offers industry insights, professional data visualization, and authoritative resources to help you make well-informed decisions for your industrial welding projects.

1. Industry Trends and Market Dynamics for E6011 Welding Rod

The e6011 welding rod (also referenced as 6011 rod or 6011 electrode) is among the most utilized consumables in stick welding processes worldwide. The global welding consumables market, according to Research & Markets 2023 data, is projected to reach USD 19.5 billion by 2027 at a 5.2% CAGR, with E6011 rods maintaining a strong share due to their multi-material adaptability and field-proven performance.

- Consistently in top-3 global best-selling stick electrodes

- Preferred for site repairs in construction, pipelines, and shipyards

- Growth supported by robust infrastructure, energy, and manufacturing sectors

Key drivers include increasing infrastructure projects, demand for versatile and reliable joining solutions (notably for unclean/oil-contaminated metals), and a shift towards higher safety-certified products.

2. Technical Parameters and Product Specification Table

E6011 welding rod derives its name from the AWS (American Welding Society) classification, signifying:

- 60 = Minimum tensile strength of 60,000 psi

- 1 = Usable in all welding positions

- 1 = Fast freeze, high cellulose potassium coating

| Parameter | E6011 Specification | Electrodo 6011 (SteelToolsChina) Main Data | Industry Standard (AWS A5.1/ISO 2560) |

|---|---|---|---|

| Diameter (mm) | 2.0 / 2.5 / 3.2 / 4.0 / 5.0 | 2.5, 3.2, 4.0 | 2.0–5.0 |

| Length (mm) | 300 / 350 / 400 | 300, 350, 400 | ≥300 |

| Tensile Strength (MPa) | ≥ 430 | ≥ 430 | ≥ 430 |

| Yield Strength (MPa) | ≥ 330 | ≥ 330 | ≥ 330 |

| Elongation (%) | ≥ 17 | ≥ 18 | ≥ 17 |

| Coating Type | High Cellulose Potassium | High Cellulose Potassium | High Cellulose Potassium |

| Current Type | AC/DC+ | AC/DC+ | AC/DC+ |

| Recommended Amp (A) | 45–160 | 50–170 | 50–160 |

| ISO/ANSI Certification | ISO 2560, ANSI/AWS A5.1 | ISO 2560, ANSI/AWS A5.1 | ISO 2560, ANSI/AWS A5.1 |

3. Electrodo 6011 Welding Rod E6011 Manufacture: Manufacturing Process Flow

The modern e6011 welding rod manufacturing integrates advanced metallurgy, precision machinery, and rigorous multi-stage inspection, ensuring every piece meets international performance and safety standards (ISO 2560, ANSI/AWS A5.1).

Manufacturing Flow Chart of E6011 Welding Rod

Steel core selection, chemical analysis

Precision CNC wire forming, dimensional quality check

High-cellulose, potassium-rich powder mix (blending/analysis)

Automatic extrusion & uniform rod coating

Multi-stage drying ovens; precise temp & humidity control

ISO/ANSI checks—mechanical, chemical, X-ray, salt-spray test

Each stage is monitored, ensuring consistent e6011 welding rod quality across all batches.

- Steel core: SAE 1006/1008, ultra-low carbon

- Coating: Potassium cellulose, anti-oxidant additives

- Machining: Wire drawing, CNC cutting for dimensional repeatability

- Certification: ISO 2560, AWS A5.1, and customer-specific benchmarks

- Testing: Mechanical, radiographic, salt-spray, bending/flexibility tests

- Lifespan: Up to 3 years+ under proper storage

4. Technical Advantages of E6011 Welding Rod in Key Application Scenarios

- Deep Arc Penetration: Superior for galvanized/dirty/rusty surfaces, ensuring weld integrity

- All-position Welding: Efficient for horizontal, vertical, overhead and flat positions

- Flexible Polarity: Usable on both AC and DC welding machines

- Self-cleaning Slag: Saves post-process time, prevents weld inclusion

- Low Hydrogen: Reduces risk of cold cracks, improving safety in critical installations

- Certifications: ISO 2560 and AWS A5.1 compliance guarantees international acceptability

- Wide Material Suitability: Excellent on carbon/mild steel, even with contaminants

These advantages make the e6011 welding rod the preferred choice for sectors such as:

- Petrochemical & Pipeline

- Metallurgy & Steel Fabrication

- Municipal Water & Sewage Infrastructure

- Heavy Machinery Manufacturing

- Shipbuilding & Marine Engineering

- Construction—Beams, Rebar, Scaffolding

5. Comparative Analysis: Electrodo 6011 Welding Rod E6011 Manufacture vs. Mainstream Competitors

To assist procurement and technical professionals, we present a comparison of key technical indicators of Electrodo 6011 Welding Rod E6011 Manufacture (product link) with leading brands: Lincoln Electric, ESAB, and Tianjin Bridge. All perform within AWS/ISO ranges but offer unique attributes.

| Electrodo 6011 E6011 | Lincoln Electric | ESAB | Tianjin Bridge | |

|---|---|---|---|---|

| Certifications | ISO 2560, AWS A5.1 | ISO 2560, AWS A5.1 | ISO 2560, AWS A5.1 | ISO 2560, AWS A5.1 |

| Anti-corrosion Feature | Enhanced (salt-spray >1000h) | Standard | Standard | Standard |

| Price Level (USD/kg) | 2.70–2.95 | 3.10–3.30 | 3.00–3.20 | 2.55–2.80 |

| Custom Lengths/Specs | Yes | No | Limited | Yes |

| OEM/ODM Service | Available | Not Available | Not Available | Available |

| Main Export Regions | Asia, EU, Americas | Americas, EU | EU, Asia | Asia, Africa |

6. Custom Solution Services for the E6011 Welding Rod

Electrodo 6011 Welding Rod E6011 Manufacture offers custom size, coating formulation, and packaging services for different industry needs:

- Diameter/length per technical drawings

- Private label (your brand on packaging)

- Special anti-corrosion or high-toughness coatings

- Material certificates and compliance to specific standards (ISO, ANSI, DNV, etc.)

- Technical support for application optimization

- Flexible batch MOQ; rapid prototyping

7. Application Cases & Client Testimonials

Case 1: Oil Pipeline Rapid Maintenance (Southeast Asia, 2023)

Challenge: High frequency of corrosion-induced leaks during monsoon.

Solution: Using e6011 welding rod for direct-on-oil-wet repairs, leveraging deep arc penetration and fast-freeze behavior.

Result: Downtime cut by 59%, repair reliability scored at 98.8% (per ISO 5817 standard inspections).

Case 2: Water Treatment Plant Overhaul (Europe, 2022)

Challenge: Weld stainless tie-in plate to old carbon steel piping in tight, overhead arrangement.

Solution: 6011 rod used due to AC/DC adaptability, operating in all positions even at 95% humidity.

Feedback: "No spatter, confident starts, clean slag—best AC stick performance in harshest site use."

Case 3: Heavy Equipment Chassis Rebuild (Latin America, 2024)

Solution: Custom-labeled E6011s provided per chassis design; lifetime on field exceeded 30% versus prior supplier (verified with ultrasonic weld scans).

Company Credentials, Certifications, and Client Trust

- Production plants certified by ISO 9001:2015

- Product supplied to large contractors, OEMs, and tier-1 EPCs globally

- Product quality traceability via batch/lot stamping

- 5+ years average supplier partnership duration

- Technical documentation available upon request

8. Delivery, Warranty & Expert Customer Support

| Item | Details |

|---|---|

| Lead Time | Standard: 10–15 days (inventory); Custom: 25–35 days (OEM/ODM batch) |

| Packaging | PE shrink box, vacuum bag + export carton or as required |

| Quality Warranty | 18 months after delivery or as per contract |

| After-sales Service | 24/7 engineer hotline, site guidance, nonconformance handling |

| Documentation | COC, Material Test Certificates (EN10204 3.1/3.2), Shipping docs |

| MOQ | 500kg (customizable for initial order) |

9. Frequently Asked Questions (FAQ)

- Q1: What is the core material used in e6011 welding rod manufacture?

- The steel core is typically SAE 1006/1008 low carbon steel, guaranteeing flexibility, stability, and optimal ferrous weld bonding.

- Q2: What industry standards are covered by E6011 rod production?

- All products are certified to ISO 2560 and ANSI/AWS A5.1, ensuring compliance for international procurement and safety audits.

- Q3: What are the recommended welding currents for 2.5mm and 3.2mm 6011 rods?

- For 2.5mm rods, use 50–90A; for 3.2mm, 90–140A. Always refer to WPS (Welding Procedure Specification) for exact site conditions.

- Q4: How is the welding rod stored to maximize lifespan and performance?

- Store in dry, ventilated areas at <60% RH and >5°C. For opened boxes, re-bake at 70–130°C for 1 hour prior to use.

- Q5: What certifications apply for welding rods used in petrochemical pipelines?

- Pipeline projects should specify rods with both ISO 2560, API 1104, or equivalent, per oil/gas operator manuals.

- Q6: Can the 6011 electrode be used on painted or oily metal surfaces?

- Yes, 6011 electrode is engineered for fast-freeze and deep penetration through minor surface contaminants.

- Q7: What technical documentation is supplied with every order?

- Mill test certificates, chemical analysis, mechanical property sheets, and batch traceability are provided as standard.

10. Authoritativeness: 3rd Party Standards and Citations

- References to industry-sourced data (e.g., AWS A5.1, ISO 2560)

- Customer testimonials and independent site test reports cited

- Product used by top-tier engineering contractors & manufacturing groups

- AWS A5.1: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding (American Welding Society)

- ISO 2560: Welding Consumables – Covered Electrodes for Manual Metal Arc Welding of Non-alloy and Fine Grain Steels

- WeldingWeb Forum: E6011/E6010 Application Experience Threads

- Practical Machinist Forum: E6011 Real World Performance

- Product page: Electrodo 6011 Welding Rod E6011 Manufacture

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025