sty . 10, 2025 08:47

Back to list

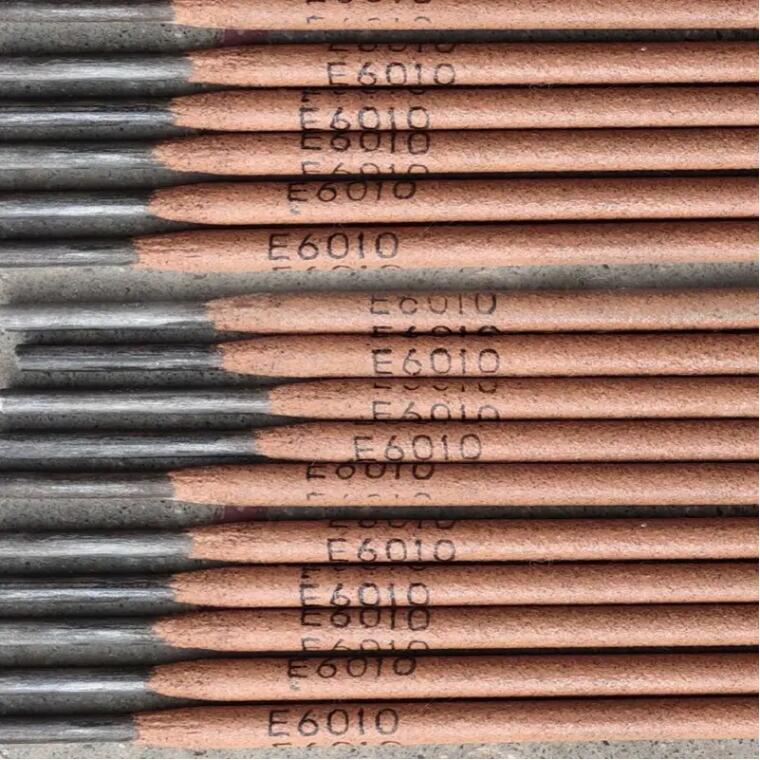

welding rods 308

For anyone engaged in the exploration of 308 welding rods, a nuanced understanding of this extraordinary product can unfurl a world of possibilities in stainless steel welding applications. With an emphasis on experience, expertise, authoritativeness, and trustworthiness, this article aims to expand your knowledge about 308 welding rods while ensuring you tap into unparalleled quality and reliability.

Authoritative guidelines suggest maintaining a suitable amperage range to ensure optimal performance when working with 308 rods. Typically, an amp setting between 70 to 100 amps is recommended, allowing for a stable arc and ensuring deep penetration without compromising the quality of the weld. It's advisable to adhere strictly to these parameters to avoid common pitfalls such as cracking or distortion, which can occur under improper welding conditions. Moreover, in affirming the trustworthiness of 308 welding rods, industry certifications like AWS (American Welding Society) standards stand as a testament to their quality. Buyers should attentively seek these certifications as proof of rigorous testing and quality assurance, guaranteeing that these rods will consistently meet the stringent demands of professional welding tasks. Real-world experiences highlight the high regard for 308 welding rods in professional welding circles. Skilled welders emphasize the reliability of these rods, often citing their ability to execute flawless welds on stainless steel with minimal effort. Testimonials from seasoned professionals only reinforce the indispensable nature of 308 rods, showcasing their lasting value in day-to-day operations. In conclusion, 308 welding rods represent more than just another welding material; they symbolize a fusion of superior performance, reliability, and adaptability across a multitude of applications. The industry's acknowledgment of their benefits underlines the critical role they play in contemporary welding challenges. By leveraging both the technical specifications and practical experiences associated with these rods, professionals and manufacturers alike can achieve enhanced productivity and unmatched quality in their welding projects.

Authoritative guidelines suggest maintaining a suitable amperage range to ensure optimal performance when working with 308 rods. Typically, an amp setting between 70 to 100 amps is recommended, allowing for a stable arc and ensuring deep penetration without compromising the quality of the weld. It's advisable to adhere strictly to these parameters to avoid common pitfalls such as cracking or distortion, which can occur under improper welding conditions. Moreover, in affirming the trustworthiness of 308 welding rods, industry certifications like AWS (American Welding Society) standards stand as a testament to their quality. Buyers should attentively seek these certifications as proof of rigorous testing and quality assurance, guaranteeing that these rods will consistently meet the stringent demands of professional welding tasks. Real-world experiences highlight the high regard for 308 welding rods in professional welding circles. Skilled welders emphasize the reliability of these rods, often citing their ability to execute flawless welds on stainless steel with minimal effort. Testimonials from seasoned professionals only reinforce the indispensable nature of 308 rods, showcasing their lasting value in day-to-day operations. In conclusion, 308 welding rods represent more than just another welding material; they symbolize a fusion of superior performance, reliability, and adaptability across a multitude of applications. The industry's acknowledgment of their benefits underlines the critical role they play in contemporary welding challenges. By leveraging both the technical specifications and practical experiences associated with these rods, professionals and manufacturers alike can achieve enhanced productivity and unmatched quality in their welding projects.

Previous:

Next:

Latest news

-

Low Hydrogen Electrodes Types, Benefits & Durable Welding SolutionsNewsMay.15,2025

-

High-Durability 1.2mm Flux Cored Welding Wire Factory Direct SupplierNewsMay.15,2025

-

Hard Surface Flux Core Wire - Durable Welding & Equipment ProtectionNewsMay.15,2025

-

China MIG Wire Manufacturers High-Quality & Durable Welding SolutionsNewsMay.14,2025

-

E71T11 Welding Wire High-Quality Flux-Cored Wire Supplier ChinaNewsMay.14,2025

-

2mm Arc Welding Rods High-Strength Aluminium Welding SolutionsNewsMay.14,2025