Wholesale 2.6mm Welding Electrode E6013 Factory Supply for Quality Metal Fabrication

Understanding the Significance of 2.6mm 6013 Welding Electrodes in Wholesale Markets

Welding is a critical process in manufacturing and construction, and the quality of welds can significantly affect the integrity and strength of the final product. Among the various types of welding electrodes available, the 2.6mm 6013 welding electrode stands out due to its versatility and effectiveness. This article explores the characteristics of 2.6mm 6013 welding electrodes, their applications, and the importance of sourcing them through wholesale channels.

Characteristics of 2.6mm 6013 Welding Electrodes

The 6013 welding electrode is a type of coated electrode used for welding mild steel and low alloy steels. With a diameter of 2.6mm, these electrodes are suitable for both vertical and overhead welding positions. One of the most notable features of the 6013 electrode is its ability to produce a smooth, clean weld with minimal spatter. The coating on the electrode serves not only to protect the molten weld pool but also to stabilize the arc, making it easy for welders, especially beginners, to achieve good weld quality.

Moreover, the 6013 welding electrode is designed to work well with alternating current (AC) and direct current (DC), enhancing its versatility in diverse welding environments. This electrode is also known for its strong performance in terms of penetration and bead appearance, along with a decent mechanical strength, which makes it ideal for general fabrication and repair works.

Applications of 2.6mm 6013 Welding Electrodes

Due to their versatility, 2.6mm 6013 welding electrodes find utilization across various sectors. They are predominantly used in the fabrication of agricultural equipment, automotive parts, construction structures, and other metal fabrication industries. Their ability to perform well on thin steel sheets makes them especially popular for maintenance and repair applications.

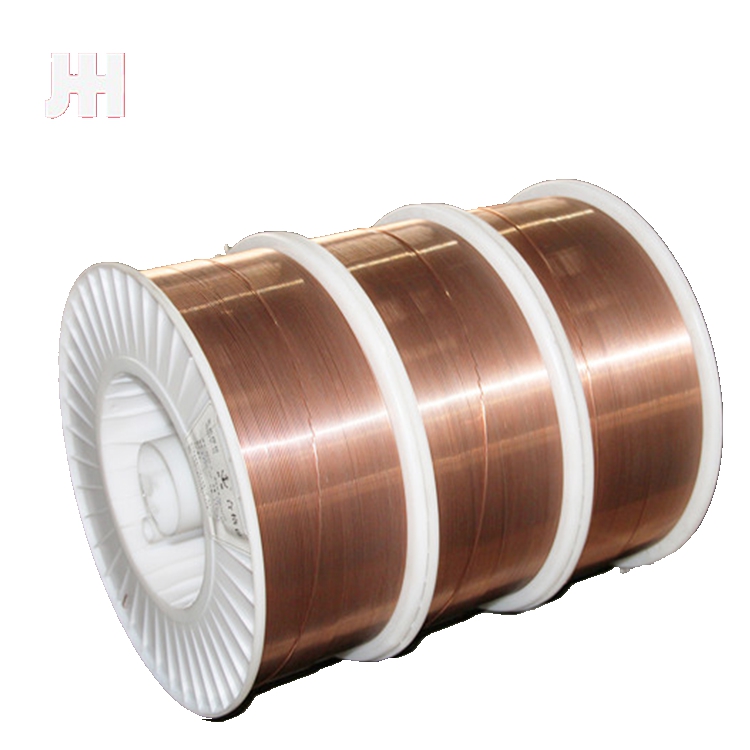

wholesale 2.6mm welding electrode 6013 factory

In addition, the 6013 electrodes are favored for welding projects that require a combination of strength and aesthetics. The smooth finish achieved with these electrodes reduces the need for additional finishing work, resulting in time and cost savings for manufacturers and welders alike.

Importance of Wholesale Procurement

When it comes to sourcing 2.6mm 6013 welding electrodes, procuring them through wholesale channels can provide significant benefits. Wholesale suppliers often offer competitive prices, allowing businesses to save on costs while ensuring they have a consistent supply of welding materials. Buying in bulk also minimizes the frequency of orders, which is particularly advantageous for companies engaged in large-scale projects or high-volume production.

Furthermore, wholesale suppliers may provide a wider range of options, including different packaging configurations and quantities, which can be tailored to the specific needs of a business. This flexibility can be crucial for operations that require a particular number of electrodes for ongoing projects.

Another key advantage of wholesale procurement is relationship building with suppliers. Establishing a good rapport with a wholesale supplier can lead to better service, potential discounts on future orders, and insights into the latest industry trends and products. This relationship can be particularly beneficial in the welding industry, where advancements in technology can influence the types of electrodes used.

Conclusion

In conclusion, the 2.6mm 6013 welding electrode is a valuable tool for welders and manufacturers alike. Its versatility, ease of use, and propensity to produce quality welds make it a popular choice in a variety of applications. By sourcing these electrodes through wholesale suppliers, businesses can take advantage of cost savings and improved supply chain efficiency. As the demand for high-quality welding materials continues to grow, understanding the benefits and applications of products like the 2.6mm 6013 welding electrode is essential for success in the welding industry.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025