CO2 Gas Shielded Copper Plating Micro Wire-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

Welding technology has evolved significantly over the years, with CO2 gas shielded welding wire emerging as a cornerstone in industrial manufacturing. Among the latest innovations, the CO2 gas shielded copper-plated micro wire stands out for its exceptional performance, durability, and versatility. This article delves into the technical specifications, advantages, and applications of this cutting-edge product, while also highlighting the expertise of its manufacturer, HEBEI YUJINHONG TECNOLOGIA CO., LTD..

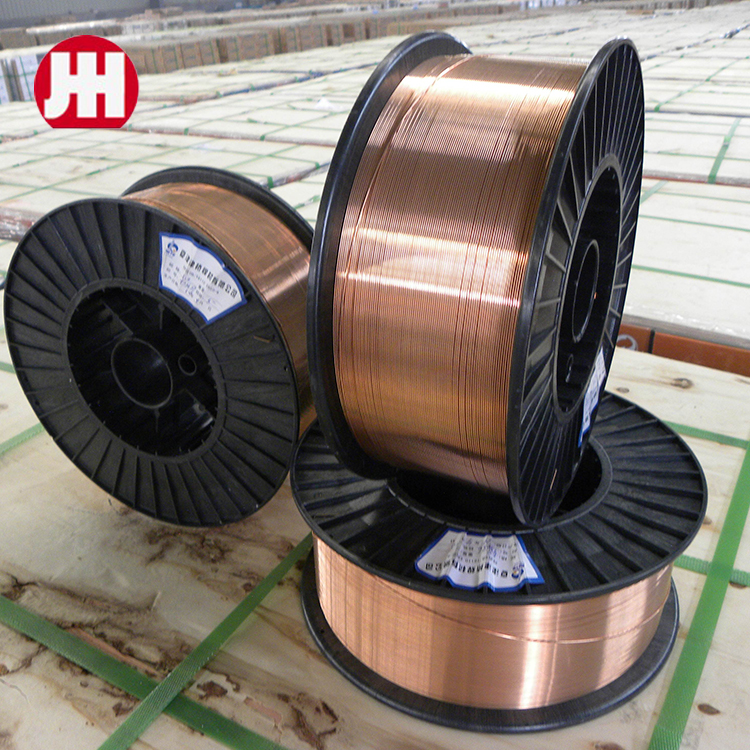

Figure 1: High-quality CO2 gas shielded welding wire with copper plating, designed for precision and durability.

Product Overview

The CO2 gas shielded copper-plated micro wire is a specialized welding consumable designed for use in CO2 gas shielded arc welding. This product is particularly suited for carbon steel applications, with the ER70S-6 grade being a prime example. It is engineered to deliver high cladding efficiency, minimal spatter, and a superior weld appearance. The wire’s copper plating serves dual purposes: corrosion resistance and enhanced electrical conductivity, making it a preferred choice for industries requiring precision and reliability.

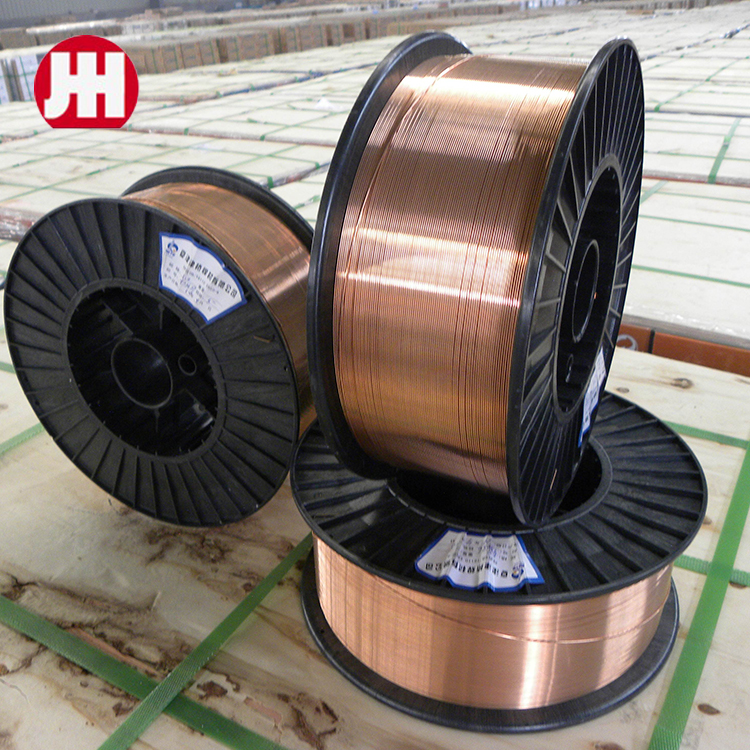

Figure 2: Copper-plated welding wire in a flux-cored application, showcasing its adaptability to various welding techniques.

Key Features and Advantages

The CO2 gas shielded copper-plated micro wire offers a range of benefits that make it a superior alternative to traditional welding methods. These include:

- Low Spatter and High Cladding Efficiency: The wire produces minimal spatter, ensuring a clean and aesthetically pleasing weld. This reduces post-welding cleanup and improves productivity.

- Excellent Weld Appearance: The welds achieved with this wire exhibit a smooth, uniform surface, which is critical for applications where visual quality is paramount.

- High Oxidation and Corrosion Resistance: The copper plating acts as a protective layer, preventing rust and degradation, even in harsh environments.

- Compatibility with Multiple Shielding Gases: The wire works effectively with both pure CO2 and Ar+CO2 mixtures (80% Ar, 20% CO2), offering flexibility in welding processes.

- Wide Application Range: Suitable for thin, medium, and thick plates, this wire is ideal for automotive, construction, and manufacturing sectors.

- Easy Operation and All-Position Welding: The wire’s stable arc and fast melting speed make it user-friendly, enabling welders to perform tasks in various positions without compromising quality.

Figure 3: Copper-plated micro wire in a welding setup, highlighting its role in achieving precise and durable welds.

Technical Specifications

The following table outlines the critical technical parameters of the CO2 gas shielded copper-plated micro wire:

| Parameter | Details |

|---|---|

| Material Grade | ER70S-6 (Carbon Steel) |

| Shielding Gas | CO2 or 80% Ar + 20% CO2 |

| Wire Diameter | 0.8mm – 1.6mm (varies by application) |

| Copper Plating Thickness | 0.001 – 0.003mm (optimized for conductivity and corrosion resistance) |

| Ultimate Tensile Strength | 500 MPa (for ER70S-6 grade) |

| Welding Positions | PA, PB, PC, PD, PE, PF (all positions) |

| Hydrogen Content | Very low, ensuring minimal crack sensitivity |

| Porosity Sensitivity | Low, reducing the risk of weld defects |

Applications and Industry Use Cases

The CO2 gas shielded copper-plated micro wire is widely used across diverse industries due to its adaptability and performance. Key applications include:

- Automotive Manufacturing: Ideal for welding vehicle frames, chassis, and structural components, where precision and strength are critical.

- Construction and Heavy Equipment: Used in the fabrication of steel structures, bridges, and machinery, where durability and resistance to environmental factors are essential.

- Shipbuilding: The wire’s corrosion resistance makes it suitable for marine environments, where exposure to saltwater is a concern.

- Industrial Fabrication: Commonly employed in the production of pressure vessels, storage tanks, and pipelines, where high-quality welds are required.

- Repair and Maintenance: The wire’s ease of use and all-position welding capability make it a preferred choice for field repairs and maintenance tasks.

Company Background: HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

Manufactured by HEBEI YUJINHONG TECNOLOGIA CO., LTD., this product reflects the company’s commitment to innovation and quality. With years of experience in the welding industry, HEBEI YUJINHONG has established itself as a trusted supplier of advanced welding consumables. The company’s rigorous quality control processes ensure that every batch of CO2 gas shielded copper-plated micro wire meets international standards.

HEBEI YUJINHONG’s production facilities utilize cutting-edge technology to maintain strict control over raw material sourcing, processing, and final inspection. This attention to detail ensures that the wire delivers consistent performance, even under demanding conditions. The company also provides comprehensive after-sales support, including technical guidance and product recommendations, to help customers achieve optimal results.

Industry Standards and Compliance

As a leader in welding technology, HEBEI YUJINHONG TECNOLOGIA CO., LTD. adheres to stringent industry standards to ensure the safety and reliability of its products. The CO2 gas shielded copper-plated micro wire complies with the following standards:

- ISO 14175: Specifies the composition and classification of gas-shielded arc welding consumables.

- ASTM A532: Defines the requirements for carbon steel welding rods and electrodes.

- GB/T 8110: Chinese national standards for gas-shielded arc welding wires.

These certifications underscore the product’s reliability and suitability for both domestic and international markets. For more information on industry standards, visit the National Institute of Standards and Technology (NIST), which plays a pivotal role in developing and promoting measurement standards across industries.

Conclusion

The CO2 gas shielded copper-plated micro wire represents a significant advancement in welding technology, offering unparalleled performance, versatility, and durability. Its unique combination of features—such as low spatter, high cladding efficiency, and corrosion resistance—makes it an ideal choice for a wide range of industrial applications. Backed by the expertise of HEBEI YUJINHONG TECNOLOGIA CO., LTD., this product continues to set new benchmarks in the welding industry.

For further details on the product specifications, applications, or to explore other welding solutions, visit the CO2 Gas Shielded Copper Plating Micro Wire page or contact HEBEI YUJINHONG TECNOLOGIA CO., LTD. directly.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov/.

-

What is a medium-frequency pulse? What types of welding are suitable for?NotíciasNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?NotíciasNov.21,2025

-

Welding Knowledge 6NotíciasNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?NotíciasNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?NotíciasNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016NotíciasNov.17,2025

CO2 Gas Shielded Copper Plating Micro Wire-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

Welding technology has evolved significantly over the years, with CO2 gas shielded welding wire emerging as a cornerstone in industrial manufacturing. Among the latest innovations, the CO2 gas shielded copper-plated micro wire stands out for its exceptional performance, durability, and versatility. This article delves into the technical specifications, advantages, and applications of this cutting-edge product, while also highlighting the expertise of its manufacturer, HEBEI YUJINHONG TECNOLOGIA CO., LTD..

Figure 1: High-quality CO2 gas shielded welding wire with copper plating, designed for precision and durability.

Product Overview

The CO2 gas shielded copper-plated micro wire is a specialized welding consumable designed for use in CO2 gas shielded arc welding. This product is particularly suited for carbon steel applications, with the ER70S-6 grade being a prime example. It is engineered to deliver high cladding efficiency, minimal spatter, and a superior weld appearance. The wire’s copper plating serves dual purposes: corrosion resistance and enhanced electrical conductivity, making it a preferred choice for industries requiring precision and reliability.

Figure 2: Copper-plated welding wire in a flux-cored application, showcasing its adaptability to various welding techniques.

Key Features and Advantages

The CO2 gas shielded copper-plated micro wire offers a range of benefits that make it a superior alternative to traditional welding methods. These include:

- Low Spatter and High Cladding Efficiency: The wire produces minimal spatter, ensuring a clean and aesthetically pleasing weld. This reduces post-welding cleanup and improves productivity.

- Excellent Weld Appearance: The welds achieved with this wire exhibit a smooth, uniform surface, which is critical for applications where visual quality is paramount.

- High Oxidation and Corrosion Resistance: The copper plating acts as a protective layer, preventing rust and degradation, even in harsh environments.

- Compatibility with Multiple Shielding Gases: The wire works effectively with both pure CO2 and Ar+CO2 mixtures (80% Ar, 20% CO2), offering flexibility in welding processes.

- Wide Application Range: Suitable for thin, medium, and thick plates, this wire is ideal for automotive, construction, and manufacturing sectors.

- Easy Operation and All-Position Welding: The wire’s stable arc and fast melting speed make it user-friendly, enabling welders to perform tasks in various positions without compromising quality.

Figure 3: Copper-plated micro wire in a welding setup, highlighting its role in achieving precise and durable welds.

Technical Specifications

The following table outlines the critical technical parameters of the CO2 gas shielded copper-plated micro wire:

| Parameter | Details |

|---|---|

| Material Grade | ER70S-6 (Carbon Steel) |

| Shielding Gas | CO2 or 80% Ar + 20% CO2 |

| Wire Diameter | 0.8mm – 1.6mm (varies by application) |

| Copper Plating Thickness | 0.001 – 0.003mm (optimized for conductivity and corrosion resistance) |

| Ultimate Tensile Strength | 500 MPa (for ER70S-6 grade) |

| Welding Positions | PA, PB, PC, PD, PE, PF (all positions) |

| Hydrogen Content | Very low, ensuring minimal crack sensitivity |

| Porosity Sensitivity | Low, reducing the risk of weld defects |

Applications and Industry Use Cases

The CO2 gas shielded copper-plated micro wire is widely used across diverse industries due to its adaptability and performance. Key applications include:

- Automotive Manufacturing: Ideal for welding vehicle frames, chassis, and structural components, where precision and strength are critical.

- Construction and Heavy Equipment: Used in the fabrication of steel structures, bridges, and machinery, where durability and resistance to environmental factors are essential.

- Shipbuilding: The wire’s corrosion resistance makes it suitable for marine environments, where exposure to saltwater is a concern.

- Industrial Fabrication: Commonly employed in the production of pressure vessels, storage tanks, and pipelines, where high-quality welds are required.

- Repair and Maintenance: The wire’s ease of use and all-position welding capability make it a preferred choice for field repairs and maintenance tasks.

Company Background: HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

Manufactured by HEBEI YUJINHONG TECNOLOGIA CO., LTD., this product reflects the company’s commitment to innovation and quality. With years of experience in the welding industry, HEBEI YUJINHONG has established itself as a trusted supplier of advanced welding consumables. The company’s rigorous quality control processes ensure that every batch of CO2 gas shielded copper-plated micro wire meets international standards.

HEBEI YUJINHONG’s production facilities utilize cutting-edge technology to maintain strict control over raw material sourcing, processing, and final inspection. This attention to detail ensures that the wire delivers consistent performance, even under demanding conditions. The company also provides comprehensive after-sales support, including technical guidance and product recommendations, to help customers achieve optimal results.

Industry Standards and Compliance

As a leader in welding technology, HEBEI YUJINHONG TECNOLOGIA CO., LTD. adheres to stringent industry standards to ensure the safety and reliability of its products. The CO2 gas shielded copper-plated micro wire complies with the following standards:

- ISO 14175: Specifies the composition and classification of gas-shielded arc welding consumables.

- ASTM A532: Defines the requirements for carbon steel welding rods and electrodes.

- GB/T 8110: Chinese national standards for gas-shielded arc welding wires.

These certifications underscore the product’s reliability and suitability for both domestic and international markets. For more information on industry standards, visit the National Institute of Standards and Technology (NIST), which plays a pivotal role in developing and promoting measurement standards across industries.

Conclusion

The CO2 gas shielded copper-plated micro wire represents a significant advancement in welding technology, offering unparalleled performance, versatility, and durability. Its unique combination of features—such as low spatter, high cladding efficiency, and corrosion resistance—makes it an ideal choice for a wide range of industrial applications. Backed by the expertise of HEBEI YUJINHONG TECNOLOGIA CO., LTD., this product continues to set new benchmarks in the welding industry.

For further details on the product specifications, applications, or to explore other welding solutions, visit the CO2 Gas Shielded Copper Plating Micro Wire page or contact HEBEI YUJINHONG TECNOLOGIA CO., LTD. directly.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov/.