Premium Carbon Steel Welding Wire for Strong, Reliable Welds

In the demanding world of B2B manufacturing and industrial fabrication, the choice of welding consumables is paramount to ensuring structural integrity, operational efficiency, and long-term durability. Among the most critical components, carbon steel welding wire stands out as a foundational material for a vast array of applications. This comprehensive guide delves into its critical aspects, from manufacturing intricacies and technical specifications to diverse application scenarios and the benefits offered by high-quality products like our Copper Coated Welding Wire for carbon steel. We aim to equip B2B decision-makers and engineers with the knowledge to make informed choices that drive project success and enhance operational longevity.

Industry Trends and Market Dynamics in Welding Consumables

The global welding consumables market is experiencing significant growth, driven by expansion in infrastructure development, automotive manufacturing, energy sectors, and heavy machinery production. Analysts project the market to reach USD 18-20 billion by 2027, with a Compound Annual Growth Rate (CAGR) of approximately 4-5%. Key trends influencing the demand for carbon steel welding wire include the increasing adoption of automated and robotic welding processes, necessitating consistent wire feeding and superior arc stability. Furthermore, stricter environmental regulations are pushing for welding wires with lower fume emissions and higher deposition efficiency. There's also a growing emphasis on specialized alloys and coatings to meet extreme performance requirements, particularly in corrosion resistance and high-temperature applications. The demand for various types, including carbon steel mig wire and carbon steel tig rod, remains robust as industries seek reliable, cost-effective solutions for joining mild and low-alloy steels.

Innovation in wire manufacturing focuses on improving mechanical properties, such as tensile strength and impact toughness, while ensuring excellent bead appearance and minimal spatter. Manufacturers are also exploring advanced packaging solutions to preserve wire quality and reduce waste on job sites. The market is highly competitive, with a strong focus on quality certifications and adherence to international standards, underscoring the importance of selecting reputable suppliers who prioritize product consistency and performance.

Detailed Manufacturing Process Flow of Carbon Steel Welding Wire

The production of high-quality carbon steel welding wire involves a sophisticated, multi-stage process designed to achieve precise chemical composition, mechanical properties, and surface finish. Our Copper Coated Welding Wire for carbon steel undergoes stringent quality control at every step to ensure superior performance.

Key Stages:

- Raw Material Selection: The process begins with carefully selected high-quality steel rods (often low-carbon steel) with controlled chemical composition, ensuring the desired metallurgical properties in the final weld. Strict adherence to standards for elements like carbon, manganese, and silicon is crucial.

- Wire Rod Descaling: The incoming steel rods are chemically or mechanically descaled to remove surface impurities, rust, and mill scale. This step is critical to prevent defects during drawing and to ensure proper copper coating adhesion.

- Wire Drawing: The descaled rods are then drawn through a series of progressively smaller dies. This cold drawing process reduces the wire's diameter, increases its tensile strength, and refines its grain structure. Multiple drawing passes are often required, with intermediate annealing treatments to restore ductility and prevent work hardening.

- Cleaning and Copper Coating: After drawing to the desired diameter, the wire undergoes thorough cleaning to remove any drawing lubricants or contaminants. It is then submerged in an electrolytic copper plating bath. The thin, uniform copper coating serves multiple purposes: it prevents corrosion, enhances electrical conductivity (critical for MIG/MAG welding), improves current transfer, and provides excellent feedability through welding guns by reducing friction.

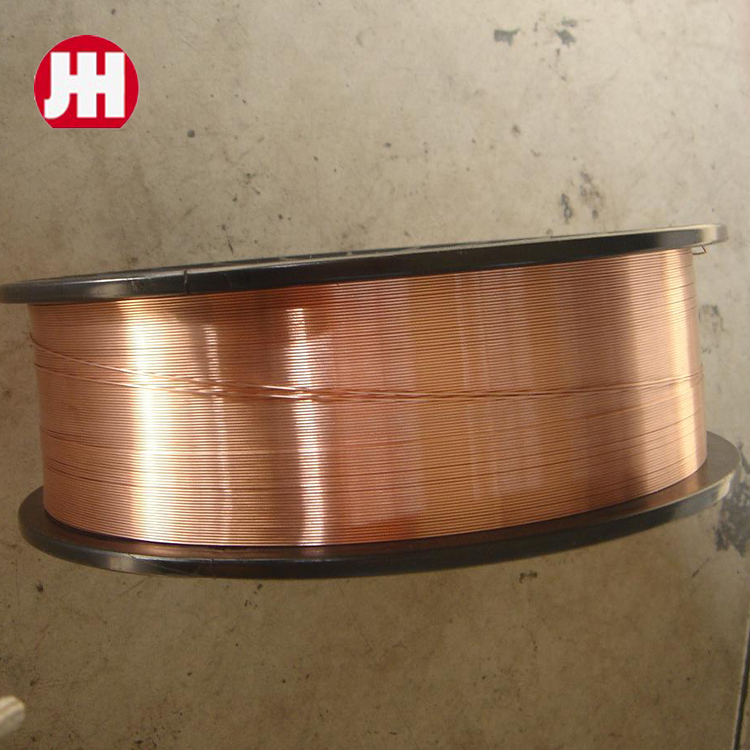

- Spooling and Packaging: The finished copper-coated wire is precisely wound onto spools of various sizes (e.g., 5kg, 15kg, 20kg) using automated coiling machines. Proper winding ensures tangle-free feeding during welding operations. The spools are then packaged, often in moisture-resistant materials, to protect against environmental degradation during storage and transit.

-

Quality Control and Testing: Throughout the entire process, rigorous quality control measures are implemented. This includes:

- Chemical analysis of raw materials and finished wire.

- Mechanical property testing (tensile strength, yield strength, elongation, impact toughness).

- Surface quality inspection (coating thickness, adhesion, absence of defects).

- Feedability and arc stability tests.

- Compliance with international standards such as ISO 14341, AWS A5.18, and EN ISO 17632.

This meticulous process ensures that our welding wires deliver consistent, high-performance results, offering advantages such as energy saving through optimized arc characteristics and superior corrosion resistance due to the high-quality copper coating, which extends the service life of both the wire and the welded joint. Target industries include petrochemical, metallurgy, and water supply & drainage, where reliability is non-negotiable.

Technical Specifications and Parameters

Understanding the technical specifications of carbon steel welding wire is crucial for selecting the right product for specific applications. These parameters directly influence weld quality, mechanical properties, and overall project efficiency. Our Copper Coated Welding Wire for carbon steel is engineered to meet or exceed international standards, providing consistent performance across various welding environments.

Typical Product Specification Table:

| Parameter | Value/Description | Padrão |

|---|---|---|

| Classification | AWS A5.18 ER70S-6 / ISO 14341-A G 42 4 C1 3Si1 | AWS, ISO |

| Wire Diameter | 0.8mm, 1.0mm, 1.2mm, 1.6mm (0.030", 0.035", 0.045", 0.062") | ANSI/AWS |

| Tensile Strength (min) | 500 MPa (72.5 ksi) | AWS A5.18 |

| Yield Strength (min) | 420 MPa (61.0 ksi) | AWS A5.18 |

| Elongation (min) | 22% | AWS A5.18 |

| Impact Toughness (Charpy V-notch) | >47 J @ -30°C (>35 ft-lb @ -20°F) | AWS A5.18 |

| Shielding Gas | 100% CO2 or Ar+CO2 mixtures | N/A |

| Copper Coating Uniformity | Excellent, minimal flaking | Internal QC |

| Packaging | 5kg, 15kg, 20kg plastic spools, bulk drums | N/A |

The chemical composition, particularly the silicon (Si) and manganese (Mn) content, is carefully balanced in ER70S-6 wire to provide excellent deoxidizing capabilities, essential for welding over mill scale and rust, thereby reducing porosity and improving weld metal quality. This ensures robust and reliable joints critical in demanding industrial applications.

Technical Advantages and Performance

Our Copper Coated Welding Wire for carbon steel offers distinct technical advantages that translate into significant operational benefits for B2B users. These advantages are crucial for optimizing welding processes, reducing costs, and ensuring the longevity of fabricated structures.

- Superior Arc Stability and Smooth Feeding: The precise manufacturing process and uniform copper coating ensure exceptional arc stability, minimizing spatter and leading to smoother, cleaner welds. The consistent wire diameter and surface finish facilitate effortless feeding through welding gun liners, significantly reducing downtime caused by tangles or blockages. This is particularly beneficial for high-volume automated welding using carbon steel mig wire.

- Enhanced Mechanical Properties: Engineered to deliver high tensile strength, yield strength, and excellent impact toughness, our wires ensure robust and durable weld joints that can withstand significant mechanical stress and dynamic loads. This is critical for structural applications where safety and reliability are paramount.

- Excellent Wetting and Bead Appearance: The optimized chemical composition promotes superior wetting action, allowing the molten weld pool to flow smoothly and deeply into the base material. This results in well-formed, aesthetically pleasing weld beads with minimal undercut and good penetration, reducing the need for post-weld grinding and finishing.

- Reduced Spatter and Fume Emissions: Advanced metallurgical design and consistent copper coating contribute to significantly lower spatter levels, leading to less material waste and reduced cleanup time. Furthermore, the formulation helps in minimizing harmful fume emissions, contributing to a safer working environment and compliance with occupational health standards.

- Corrosion Resistance and Extended Service Life: The copper coating acts as a protective layer, inhibiting rust and corrosion on the wire itself during storage. The resulting weld metal also exhibits improved resistance to environmental degradation, extending the service life of welded components, especially in challenging environments.

- Versatility Across Welding Positions: Our welding wires are designed for excellent performance in all welding positions, offering flexibility for complex fabrication tasks. This versatility streamlines workflow and reduces the need for multiple wire types.

Application Scenarios and Target Industries

The robust and versatile nature of our Copper Coated Welding Wire makes it indispensable across a broad spectrum of industrial applications. Its ability to produce high-strength, ductile welds with excellent integrity positions it as a go-to choice for critical structural and manufacturing tasks.

- Automotive Manufacturing: Used extensively in the fabrication of chassis components, exhaust systems, body panels, and other structural parts where high strength and consistent weld quality are critical for vehicle safety and performance.

- Shipbuilding and Marine Structures: For joining hull sections, deck structures, bulkheads, and other components requiring high strength and resistance to harsh marine environments. The reliability of these welds is paramount for maritime safety.

- Construction and Structural Fabrication: Essential for welding beams, columns, trusses, bridges, and general structural steelwork in commercial and industrial construction projects. The ability to achieve robust joints efficiently is key to project timelines and structural integrity.

- Heavy Machinery and Equipment: Utilized in the assembly and repair of agricultural machinery, mining equipment, earthmoving machinery, and industrial cranes, where components are subjected to extreme loads and abrasive conditions.

- Pressure Vessels and Storage Tanks: Crucial for welding components of pressure vessels, boilers, and storage tanks used in the petrochemical, oil & gas, and chemical processing industries, where weld integrity is vital for containing high pressures and hazardous materials.

- Pipeline Construction: Employed in the fabrication of pipes for water supply & drainage, oil, and gas transportation, requiring robust welds that can withstand internal pressure and external stresses over long distances. High-quality carbon steel tig rod is often preferred for root passes in critical pipe welding.

- General Fabrication and Repair: From manufacturing gates and fences to repairing industrial tools and components, its versatility makes it a staple for general metalworking and maintenance operations.

Vendor Comparison and Selection Criteria

Choosing the right supplier for carbon steel welding wire is as critical as selecting the product itself. The market offers numerous vendors, each with varying levels of quality, service, and specialization. A thorough comparison based on key criteria ensures reliable supply and consistent weld quality.

Key Comparison Factors:

- Product Quality & Consistency: Adherence to international standards (AWS, ISO, EN), consistent chemical composition, mechanical properties, and coating uniformity. Look for certifications and internal quality control protocols.

- Technical Support & Expertise: The ability of the vendor to provide expert advice, troubleshooting, and application-specific recommendations. This is invaluable for optimizing welding processes.

- Supply Chain Reliability: Timely delivery, inventory management, and responsiveness to order fluctuations. A robust supply chain minimizes production delays.

- Customization Capabilities: For unique projects, the ability to tailor wire diameters, packaging, or even specific chemical compositions can be a significant advantage.

- Cost-Effectiveness & Value: While price is a factor, focus on the total cost of ownership, including weld quality, reduced rework, and productivity gains.

- Reputation & References: Customer feedback, industry recognition, and long-term partnerships signal a trustworthy vendor.

Vendor Comparison Table (Illustrative):

| Feature/Vendor | Our Product (SteelToolsChina) | Competitor A | Competitor B |

|---|---|---|---|

| Quality Certifications | ISO 9001, AWS A5.18, CE | AWS A5.18 | ISO 9001 |

| Arc Stability & Feedability | Excellent (Copper Coated) | Good | Padrão |

| Spatter Level | Low | Moderate | High |

| Technical Support | Dedicated, expert team | Basic online support | Limited |

| Customization | Available (diameter, packaging) | Limited | Not available |

| Global Reach | Worldwide distribution | Regional | National |

Customized Solutions for Specialized Needs

While standard classifications like ER70S-6 cover a wide range of applications for carbon steel, some specialized projects demand tailored solutions. Recognizing this, SteelToolsChina offers comprehensive customization capabilities for our copper-coated welding wire. Our engineering team collaborates closely with clients to develop products that meet unique specifications, ensuring optimal performance for even the most challenging welding scenarios.

Customization options include specific wire diameters not commonly stocked, bespoke spool sizes or bulk packaging configurations for automated systems, and even slight adjustments to chemical composition for enhanced properties like increased corrosion resistance or improved impact toughness at sub-zero temperatures. Whether it's a specialized carbon steel tig rod for precision work or a unique blend for high-volume automated MIG lines, our flexibility in manufacturing processes allows us to deliver solutions that precisely align with your project requirements and operational workflows.

Application Case Studies and Customer Feedback

Real-world performance demonstrates the true value of high-quality welding consumables. Our Copper Coated Welding Wire has been successfully deployed in numerous critical projects, yielding consistent results and high customer satisfaction.

Case Study 1: Large-Scale Structural Steel Fabrication

A major construction firm was engaged in fabricating a complex steel structure for a new industrial plant. The project demanded high-deposition rates, minimal spatter, and exceptional weld integrity to meet stringent structural codes. By switching to our 1.2mm copper-coated carbon steel mig wire, they experienced:

- A 15% increase in welding speed due to superior arc stability and feedability.

- A 20% reduction in post-weld cleanup time due to significantly less spatter.

- Consistent X-ray quality welds, minimizing costly rework.

"The SteelToolsChina welding wire dramatically improved our efficiency and weld quality. We met our aggressive deadlines without compromising on structural integrity." - Project Manager, Industrial Construction Corp.

Case Study 2: Automotive Component Manufacturing

An automotive parts supplier required a welding wire that could deliver ultra-consistent welds for robotic assembly lines, ensuring repeatable quality and minimizing component rejection rates. Their previous wire caused occasional feeding issues and inconsistent penetration. Implementing our 0.8mm Copper Coated Welding Wire led to:

- Near-zero wire feeding problems, enhancing robotic uptime.

- Improved weld penetration and bead profile consistency, critical for fatigue-sensitive parts.

- A notable reduction in defect rates, directly impacting production costs.

"Our robotic welding cells run flawlessly with SteelToolsChina's wire. The consistent quality is a game-changer for high-volume automotive production." - Production Engineer, Tier 1 Automotive Supplier.

Meeting Google Standards: Expertise, Experience, Authoritativeness, Trustworthiness

At SteelToolsChina, our commitment extends beyond merely supplying high-quality welding consumables; we strive to be a trusted partner through adherence to the highest industry benchmarks, reflecting Expertise, Experience, Authoritativeness, and Trustworthiness ().

Expertise & Experience:

Our team comprises seasoned metallurgists and welding engineers with decades of collective experience in consumable development and application. This deep domain knowledge ensures that every batch of Copper Coated Welding Wire is manufactured to precise specifications, leveraging advanced metallurgical principles and extensive field testing. We've honed our processes over many years, understanding the nuances of various welding challenges and delivering solutions that perform reliably in the toughest industrial environments.

Authoritativeness:

SteelToolsChina proudly holds ISO 9001:2015 certification for our quality management systems, assuring consistent product quality. Our welding wires conform strictly to international standards such as AWS A5.18 (e.g., ER70S-6) and EN ISO 14341, validated by independent third-party laboratories. We partner with leading global engineering and fabrication companies, who rely on our products for their critical projects. Our extensive portfolio of successful projects and long-standing client relationships, spanning over 15 years in the industry, serve as a testament to our authoritative standing. Detailed test reports, including material certifications (MTCs), are available for all products upon request, providing verifiable data for every batch of carbon steel welding wire.

Trustworthiness:

Transparency and reliability form the bedrock of our operations. We offer clear lead times, robust warranty commitments, and dedicated after-sales support. Our commitment to ethical business practices and customer satisfaction has fostered long-term trust within the B2B community.

Frequently Asked Questions (FAQ)

Q: What is the primary difference between ER70S-3 and ER70S-6 carbon steel welding wire?

A: ER70S-6 contains higher levels of silicon and manganese compared to ER70S-3. These additional deoxidizers make ER70S-6 more suitable for welding on base metals with moderate rust, mill scale, or other contaminants, providing superior wetting action and minimizing porosity. ER70S-3 is generally used on cleaner base metals.

Q: Can your Copper Coated Welding Wire be used for both MIG/MAG and TIG processes?

A: Our Copper Coated Welding Wire is primarily designed for MIG/MAG (Gas Metal Arc Welding) applications. For TIG (Gas Tungsten Arc Welding) of carbon steel, we offer specific carbon steel tig rod products, which are typically cut-length rods optimized for that process.

Q: What shielding gas is recommended for your copper-coated welding wire?

A: For optimal performance, 100% CO2 or a mixture of Argon (Ar) and CO2 (e.g., 75% Ar / 25% CO2 or 80% Ar / 20% CO2) is recommended. The choice depends on the desired arc characteristics, penetration, and spatter levels for your specific application.

Q: What are the typical lead times for large orders?

A: Standard lead times for common diameters and packaging range from 2-4 weeks, depending on order volume and current production schedules. For customized solutions or exceptionally large orders, lead times will be provided upon specific inquiry and order confirmation. We maintain robust inventory levels to facilitate quick turnaround where possible.

Q: What is your warranty policy?

A: SteelToolsChina provides a comprehensive warranty against manufacturing defects and material non-conformity to stated specifications. Our products are guaranteed to meet or exceed relevant international standards. Specific warranty terms and conditions are available upon request and will be detailed in our sales agreements. Customer satisfaction is our priority.

Q: How do you handle after-sales support and technical inquiries?

A: We offer dedicated after-sales support through our technical service team. Clients can reach us via phone, email, or our online portal for any technical inquiries, application assistance, or troubleshooting. Our experts are committed to providing timely and effective solutions to ensure uninterrupted operations.

Conclusion

The selection of the appropriate carbon steel welding wire is a decision that profoundly impacts project success, operational efficiency, and the long-term reliability of welded structures. Our Copper Coated Welding Wire for carbon steel is meticulously engineered and manufactured to deliver superior performance, adhering to the highest international standards. By offering exceptional arc stability, minimal spatter, excellent mechanical properties, and robust technical support, we empower B2B clients to achieve optimal welding results consistently. We are committed to fostering partnerships built on quality, reliability, and innovation, ensuring that your critical fabrication needs are met with excellence.

References

- American Welding Society (AWS). "AWS A5.18/A5.18M: Specification for Carbon Steel Electrodes and Rods for Gas Shielded Arc Welding."

- International Organization for Standardization (ISO). "ISO 14341: Welding consumables – Wire electrodes and deposits for gas shielded metal arc welding of non alloy and fine grain steels – Classification."

- Mordor Intelligence. "Welding Consumables Market - Growth, Trends, COVID-19 Impact, and Forecasts (2022 - 2027)."

- The Welding Institute (TWI). "MIG/MAG Welding Process and Consumables."

-

What is a medium-frequency pulse? What types of welding are suitable for?NotíciasNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?NotíciasNov.21,2025

-

Welding Knowledge 6NotíciasNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?NotíciasNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?NotíciasNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016NotíciasNov.17,2025