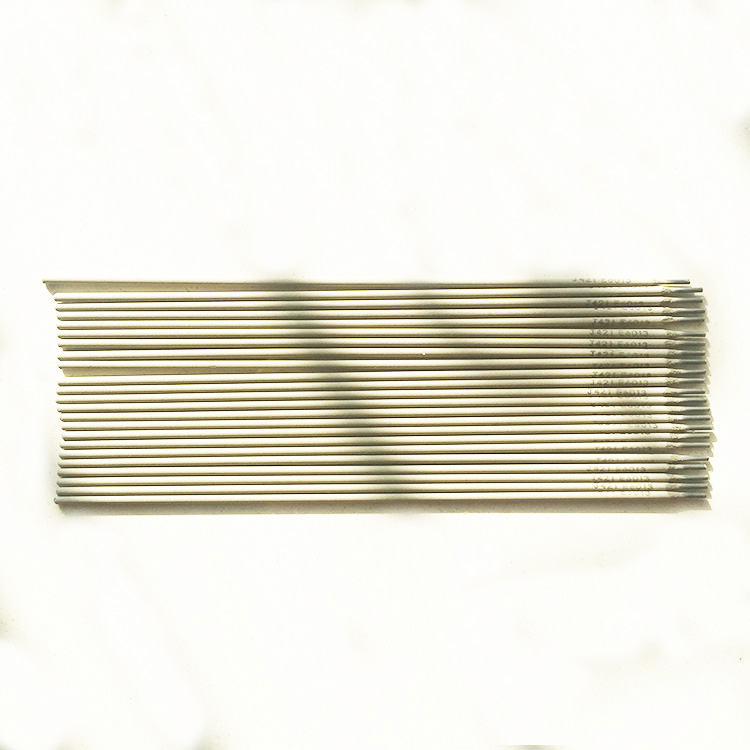

6010 welding electrode factory

The Significance of 6010 Welding Electrodes in the Manufacturing Industry

Welding is an essential process in various industries, including construction, automotive, shipbuilding, and manufacturing. Among the diverse types of welding electrodes, the 6010 welding electrode is widely recognized for its exceptional performance and versatility. This article delves into the significance of 6010 welding electrodes, their characteristics, applications, and the role of factories that produce these vital components.

Understanding 6010 Welding Electrodes

6010 welding electrodes are classified under the E6010 designation, which indicates their specific properties. The 60 signifies a minimum tensile strength of 60,000 psi, while the 1 denotes the electrode's position in which it can be used (i.e., all positions). The 0 at the end indicates that the electrode is designed for direct current (DC) use. These electrodes are typically made from a mild steel core with a covering that contains materials such as cellulose, which provides a stable and controllable arc during the welding process.

One of the defining characteristics of 6010 electrodes is their ability to produce deep penetration in various base metals. This quality makes them especially effective for welding in situations where joint preparation is minimal, or where materials may not be ideally aligned. The deep penetration helps create robust welds, essential for structural integrity in critical applications.

Applications of 6010 Welding Electrodes

6010 welding electrodes are commonly employed in various applications, including

1. Structural Welding The strength and durability of welds produced with 6010 electrodes make them ideal for structural applications. They are often used in the construction of buildings, bridges, and other large structures that require high-strength welds.

2. Pipeline Welding The deep penetration and good arc stability of 6010 electrodes make them suitable for pipeline welding. They are frequently used in the installation and repair of pipelines in oil and gas industries, ensuring reliable and leak-proof joints.

6010 welding electrode factory

3. Automotive Repair In the automotive industry, 6010 electrodes are used for repairing frame structures and other components subjected to high stress and strain. Their ability to bond well with various steel grades makes them a preferred choice for mechanics and welders.

4. Farm Equipment Manufacturing The agricultural sector also benefits from 6010 electrodes, as they are used to manufacture and repair farm equipment. The resilience of the welds produced ensures that equipment can withstand harsh working conditions.

The Role of 6010 Welding Electrode Factories

Factories specializing in the production of 6010 welding electrodes play a crucial role in meeting the demands of various industries. The manufacturing process involves several steps, including selecting the appropriate materials, creating the electrode core, applying the flux coating, and packaging the finished products.

Quality control is an integral aspect of electrode manufacturing. Factories often conduct rigorous testing to ensure their products meet industry standards and customer expectations. This includes assessing the tensile strength, flexibility, and overall performance of the electrodes during welding. Advanced technology and skilled labor work in synergy to produce reliable electrodes that clients can depend on for critical applications.

Moreover, these factories continually innovate to enhance the properties of their electrodes. Research and development efforts focus on improving the performance of the electrodes in different conditions, thus providing welders with tools that can accommodate a wide range of projects.

Conclusion

In conclusion, 6010 welding electrodes hold significant importance in the welding landscape, offering versatility, strength, and reliability across various applications. Their deep penetration capabilities make them suitable for demanding environments, while factories that produce these electrodes contribute to the efficiency and effectiveness of numerous industries. As welding technology continues to advance, the importance of high-quality welding electrodes, like the 6010, will remain paramount in ensuring the structural integrity and safety of welded constructions worldwide.

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025