E71T-1 Shielding Gas for Superior Welding Quality & Efficiency

Optimizing Welding Performance with e71t 1 shielding gas in B2B Applications

In high-stakes industrial welding, the selection of consumables is paramount. Among these, the e71t 1 shielding gas plays a critical role in achieving superior weld integrity and operational efficiency, particularly when paired with E71T-1C gas shield flux coated welding wires. This article delves into the technical intricacies, application advantages, and comprehensive considerations for B2B stakeholders leveraging this essential component in their fabrication processes. Our focus is on providing an in-depth understanding for engineers, procurement specialists, and project managers seeking to optimize their welding operations.

The synergy between the flux-cored wire and its designated shielding gas dictates arc stability, spatter levels, slag detachability, and ultimately, the mechanical properties of the weld metal. For demanding structural applications, pressure vessels, and heavy machinery, precise control over these factors is non-negotiable.

Current Industry Trends in Welding Consumables and Shielding Gases

The welding industry is experiencing rapid evolution, driven by demands for increased productivity, enhanced safety, and superior material performance. Key trends include:

- Automation and Robotics Integration: The push towards automated welding systems necessitates consumables that offer consistent performance, minimal spatter, and reliable arc characteristics to maximize uptime and reduce manual intervention. Flux-cored wires with optimized performance under e71t 1 shielding gas are ideal for these setups.

- Sustainable and Environmentally Friendly Solutions: Reducing fume emissions and energy consumption is a growing priority. Manufacturers are developing wires and gases that minimize environmental impact without compromising quality.

- Advanced Material Compatibility: As new alloys emerge, there's a constant need for welding consumables that can handle these materials, maintaining their metallurgical integrity and strength.

- Data-Driven Quality Control: The use of sensors and data analytics in welding processes allows for real-time monitoring and adjustments, ensuring consistent weld quality and compliance with stringent industry standards.

- Demand for High Deposition Rates: Large-scale fabrication projects require consumables that offer high deposition efficiency to reduce project timelines and labor costs. Gas shielded cored wire, particularly E71T-1C, excels in this area.

These trends underscore the critical need for well-engineered welding consumables like the E71T-1C wire when paired with its appropriate e71t 1 shielding gas, ensuring that modern fabrication challenges are met with robust and efficient solutions.

The Manufacturing Process of E71T-1C Gas Shield Flux Coated Welding Wire and Shielding Gas Interaction

The production of E71T-1C Gas Shield Flux Coated Welding Wire, designed to perform optimally with specific e71t 1 shielding gas (typically CO2 or Argon-CO2 blends), is a meticulous multi-stage process ensuring consistent quality and performance.

Process Flow Diagram:

- 1 Material Selection & Preparation: High-quality steel strip (e.g., low carbon steel) is carefully selected. Its surface is meticulously cleaned and degreased to ensure optimal flux adhesion.

- 2 Strip Forming: The steel strip undergoes a precision forming process, creating a U-shaped channel that will contain the flux core.

- 3 Flux Filling: A precisely formulated flux mixture, containing deoxidizers, slag formers, and alloying elements, is introduced into the U-channel. This flux is crucial for arc stability, protecting the weld metal, and influencing its metallurgical properties when using e71t 1 shielding gas.

- 4 Closing & Drawing: The U-channel is closed to fully encapsulate the flux, and the wire is then drawn through a series of dies to achieve the desired diameter. This cold-drawing process work-hardens the wire and ensures dimensional accuracy.

- 5 Baking & Drying: The wire undergoes a controlled baking process to remove moisture from the flux, preventing hydrogen-induced cracking in the final weld.

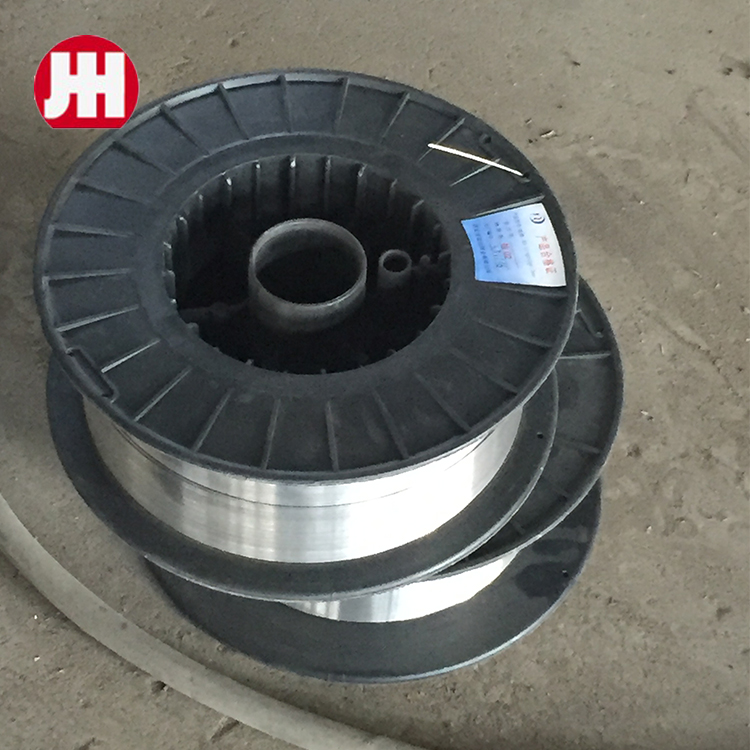

- 6 Spooling & Packaging: The finished wire is precisely spooled and packaged in moisture-resistant materials, ready for distribution.

- 7 Quality Control & Testing: Throughout the entire process, rigorous testing is conducted, including chemical analysis of the flux and wire, mechanical property tests of weld deposits, and radiographic examinations to ensure compliance with standards like AWS A5.20/A5.20M and ISO 17632.

The choice of e71t 1 shielding gas is pivotal. For E71T-1C, a 100% CO2 shielding gas is commonly specified (hence the 'C' in E71T-1C). CO2, while reactive, provides deep penetration and good bead shape. The flux chemistry is specifically engineered to synergize with CO2, promoting excellent arc stability and a robust slag system that protects the molten weld pool during solidification. This combination offers superior deposition rates and mechanical properties, making it an energy-saving and high-efficiency solution.

Target Industries: Petrochemical, power generation, metallurgy, shipbuilding, heavy equipment manufacturing, and general structural fabrication. In these scenarios, the excellent corrosion resistance and robust mechanical properties offered by this wire and gas combination ensure long service life and reduced maintenance.

Technical Specifications and Performance Metrics for E71T-1C with E71T 1 Shielding Gas

Understanding the detailed technical specifications is crucial for engineers to select the appropriate welding consumable. The E71T-1C flux-cored wire, when used with its specified e71t 1 shielding gas (100% CO2), delivers consistent mechanical and chemical properties meeting stringent industry standards.

Typical Mechanical Properties of Weld Metal (AWS A5.20/A5.20M E71T-1C with 100% CO2 Shielding)

| Property | Unit | Typical Value | AWS Requirement (Min.) |

|---|---|---|---|

| Tensile Strength | MPa (ksi) | 540 (78) | 490 (70) |

| Yield Strength (0.2% Offset) | MPa (ksi) | 470 (68) | 400 (58) |

| Elongation | % | 28 | 22 |

| Charpy V-notch Impact (at -20°C / -4°F) | J (ft·lbf) | >50 (37) | 27 (20) |

Typical Chemical Composition of Weld Metal (Wt.%)

| Element | Typical Value | AWS Requirement (Max.) |

|---|---|---|

| Carbon (C) | 0.05 - 0.12 | 0.20 |

| Manganese (Mn) | 1.00 - 1.50 | 1.60 |

| Silicon (Si) | 0.30 - 0.60 | 0.90 |

| Phosphorus (P) | 0.015 - 0.025 | 0.030 |

| Sulfur (S) | 0.010 - 0.020 | 0.030 |

Key Welding Parameters:

- Welding Positions: All positions (flat, horizontal, vertical up, overhead).

- Current Type: DC Electrode Positive (DCEP).

- Shielding Gas: 100% CO2 (for E71T-1C). Gas flow rates typically range from 15-25 L/min (30-50 CFH) depending on joint configuration and environmental conditions.

- Voltage: 22-32V, optimized for wire diameter and welding position.

- Wire Feed Speed: Governed by amperage requirements, delivering high deposition rates.

Application Scenarios and Operational Benefits

The robust characteristics of E71T-1C wire in conjunction with its specific e71t 1 shielding gas make it indispensable across a wide array of heavy fabrication and structural welding applications. Its versatility and high-performance profile contribute significantly to operational efficiency and weld integrity.

- Shipbuilding and Offshore Structures: Used for welding hulls, deck structures, and other critical components where high strength, good toughness, and all-position welding capabilities are essential. The consistent bead profile and reduced need for rework enhance productivity in these large-scale projects.

- Pressure Vessels and Boilers: For components operating under high pressure and temperature, weld integrity is paramount. The excellent mechanical properties and low hydrogen content (due to the flux and proper gas usage) minimize the risk of defects like hydrogen-induced cracking.

- Heavy Equipment Manufacturing: Construction machinery, agricultural equipment, and mining machinery demand robust welds that can withstand extreme dynamic loads and abrasive environments. E71T-1C with its specialized e71t 1 shielding gas ensures the durability and longevity of these critical components.

- General Structural Fabrication: Bridges, buildings, and industrial frameworks benefit from the high deposition rates and consistent weld quality, leading to faster project completion and compliance with structural codes.

- Pipe Welding (Large Diameter): In certain large-diameter pipe applications, particularly for root and fill passes, the wire offers a good balance of penetration and fill, reducing the number of passes required.

In each of these scenarios, the combination of high deposition rates, excellent bead appearance, minimal spatter, and superior mechanical properties translates into significant operational benefits: reduced labor costs, faster cycle times, lower rework rates, and ultimately, higher profitability for fabricators.

Technical Advantages of E71T-1C with Optimized Shielding

The judicious choice of E71T-1C flux-cored wire combined with the correct e71t 1 shielding gas yields a multitude of technical advantages that are critical for modern industrial welding applications.

- High Deposition Efficiency: Flux-cored wires generally offer higher deposition rates compared to solid wires, and the E71T-1C variant is no exception. This translates directly into faster welding speeds and reduced fabrication times, especially for thick sections and large weld volumes.

- Excellent Arc Stability and Weldability: The carefully formulated flux, synergized with 100% CO2 e71t 1 shielding gas, ensures a stable arc, minimizing spatter and providing smooth, consistent bead characteristics. This enhances operability across all positions and reduces the skill requirement for achieving high-quality welds.

- Superior Mechanical Properties: As evidenced by the typical data, weldments produced with E71T-1C exhibit excellent tensile strength, yield strength, and impact toughness, even at sub-zero temperatures. This is vital for structural integrity and performance in demanding environments.

- Good Slag Detachability and Bead Appearance: The flux system generates a self-peeling slag that is easy to remove, significantly reducing post-weld cleaning time. The resulting weld beads are smooth and aesthetically pleasing, often meeting visual inspection criteria with minimal effort.

- Low Hydrogen Content: The design of the flux and the proper use of shielding gas ensure very low diffusible hydrogen levels in the weld metal, greatly reducing the risk of hydrogen-induced cracking (HIC), a critical concern in high-strength steel fabrication.

- Versatility Across Welding Positions: E71T-1C is an all-position wire, offering flexibility in fabrication setups and allowing complex geometries to be welded efficiently without compromising quality.

- Enhanced Energy Efficiency: The high deposition rates mean less time under arc for a given weld volume, contributing to reduced energy consumption per unit of weld metal deposited.

Vendor Comparison: Key Differentiators in E71T-1C and E71T 1 Shielding Gas Supply

Selecting the right vendor for welding consumables and gases is as crucial as selecting the products themselves. B2B decision-makers must evaluate suppliers based on several critical factors beyond just price, focusing on consistent quality, technical support, and logistical capabilities.

Key Evaluation Criteria for Welding Consumables Vendors

| Criterion | High-Quality Vendor | Standard Vendor |

|---|---|---|

| Product Consistency | Rigorous QC, minimal batch variation, certified to AWS/ISO. | Variable quality, occasional batch issues, inconsistent certifications. |

| Technical Support | On-site support, expert troubleshooting, application engineers available. | Limited phone support, basic data sheets, slow response times. |

| Certifications & Compliance | Comprehensive AWS, ISO, CE, and specific industry approvals. | Basic certifications, not always up-to-date or comprehensive. |

| Supply Chain Reliability | Robust inventory, efficient logistics, on-time delivery, emergency stock. | Frequent delays, limited stock, less flexible shipping. |

| Customization & R&D | Capability for custom solutions, active R&D for new products. | Standard product lines only, no R&D focus. |

Choosing a vendor that consistently meets these criteria ensures not only superior product performance from your E71T-1C wire and e71t 1 shielding gas, but also provides a reliable partnership that minimizes operational risks and maximizes productivity. Look for suppliers with proven track records, positive customer testimonials, and a commitment to quality management systems like ISO 9001.

Customized Solutions for Specialized Welding Requirements

While standard E71T-1C wire with its corresponding e71t 1 shielding gas offers broad applicability, many B2B clients encounter unique welding challenges that require tailored solutions. A truly authoritative supplier understands these nuances and offers customization options to optimize performance for specific projects.

Customization can extend to several areas:

- Wire Diameter and Spool Size: While standard diameters (e.g., 1.2mm, 1.6mm) are common, specific applications might benefit from non-standard sizes or specialized spooling for robotic systems to minimize changeovers.

- Flux Chemistry Adjustments: For applications demanding slight variations in mechanical properties, corrosion resistance, or slag characteristics, a manufacturer with R&D capabilities can often adjust the flux formulation. This might involve fine-tuning deoxidizers or alloying elements.

- Packaging and Delivery: Tailored packaging to suit automated feeding systems or specific environmental conditions (e.g., enhanced moisture barriers) can be crucial for operational flow and product integrity.

- Comprehensive Technical Consulting: Beyond product customization, expert vendors provide consulting services to help clients optimize their entire welding process, including gas flow rates, voltage settings, and wire feed speeds, specifically for their unique base materials and joint designs.

Engaging with a vendor capable of providing these bespoke solutions ensures that clients are not just purchasing a product, but investing in a complete, optimized welding ecosystem that directly addresses their project's technical and operational demands. This collaborative approach leads to higher quality welds, reduced downtime, and significant cost savings over the project lifecycle.

Real-World Application Case Studies

The practical effectiveness of E71T-1C wire with its specialized e71t 1 shielding gas is best demonstrated through real-world applications where it has delivered significant value. These case studies highlight the tangible benefits for B2B clients.

Case Study 1: Large-Scale Bridge Construction

A major infrastructure project required welding large structural steel sections for a new bridge. The client faced challenges with achieving required deposition rates and maintaining consistent weld quality across various positions in harsh weather conditions.

- Solution Implemented: E71T-1C flux-cored wire (1.6mm) with 100% CO2 e71t 1 shielding gas.

- Results: Achieved a 25% increase in welding speed compared to previous processes, reducing project timelines by 10%. The robust arc characteristics allowed for consistent, high-quality welds even in moderate wind, minimizing shielding gas loss and maintaining optimal penetration. Post-weld cleaning time was reduced by 30% due to easily detachable slag. The welds consistently passed stringent ultrasonic and radiographic inspections.

Case Study 2: Manufacturing of Earthmoving Equipment

A manufacturer of heavy earthmoving equipment sought to improve the fatigue life and impact resistance of their bucket assemblies and chassis components, which are subjected to immense stress.

- Solution Implemented: Optimized welding parameters for E71T-1C with 100% CO2 shielding, focusing on minimizing heat input while achieving excellent fusion.

- Results: The enhanced toughness and strength provided by the E71T-1C weld metal led to a reported 15% increase in component service life, significantly reducing warranty claims and replacement costs for end-users. The improved spatter control also contributed to a cleaner working environment and less post-weld grinding.

Case Study 3: Petrochemical Plant Refurbishment

During a critical shutdown for refurbishment at a petrochemical facility, rapid and reliable welding of structural supports and pipe hangers was required, often in confined spaces.

- Solution Implemented: E71T-1C (1.2mm) for all-position welding, utilizing its excellent operability and consistent penetration.

- Results: Welders appreciated the smooth arc and low spatter, which were crucial in tight access areas. The wire's ability to perform well in vertical-up and overhead positions expedited work in challenging geometries, helping the project meet its tight deadline and minimize plant downtime, saving millions in potential production losses.

Ensuring Trust and Reliability: Our Commitment

Certifications and Compliance

Our products, including E71T-1C flux-cored welding wire and recommendations for optimal e71t 1 shielding gas, adhere to the highest international standards. We are ISO 9001 certified, ensuring rigorous quality management throughout our manufacturing processes. Our welding consumables consistently meet or exceed AWS A5.20/A5.20M and ISO 17632 classifications, providing peace of mind and guaranteeing performance. Regular third-party audits and internal quality checks are integral to our operational excellence.

Lead Time and Fulfillment

We understand the importance of timely delivery in industrial operations. Our robust supply chain and optimized logistics ensure competitive lead times for standard E71T-1C products and related e71t 1 shielding gas solutions. Typical lead times range from 7-14 business days for standard orders, with expedited options available for urgent requirements. We maintain strategic inventory levels to support immediate client needs and minimize disruption.

Warranty Commitments

All our E71T-1C welding wires are backed by a standard 12-month warranty against manufacturing defects, from the date of purchase. This commitment reflects our confidence in the quality and reliability of our products. Detailed warranty terms and conditions are available upon request. Our dedicated technical support team is available to address any performance concerns promptly.

Customer Support and After-Sales Service

Our commitment extends beyond the sale. We provide comprehensive after-sales support, including technical assistance, troubleshooting, and application guidance. Our team of experienced welding engineers is available for on-site consultations, product training, and process optimization to ensure you achieve the best possible results with our E71T-1C wire and recommended e71t 1 shielding gas. For inquiries, please contact us at info@steeltoolschina.com.

Frequently Asked Questions (FAQ)

Q: What is the primary shielding gas recommended for E71T-1C wire?

A: For E71T-1C flux-cored wire, 100% Carbon Dioxide (CO2) is the primary recommended e71t 1 shielding gas, denoted by the 'C' in its classification. This provides optimal arc characteristics and mechanical properties.

Q: Can E71T-1C be used in all welding positions?

A: Yes, E71T-1C is designed for all-position welding, offering excellent operability in flat, horizontal, vertical up, and overhead positions, provided correct parameters are maintained.

Q: What are the main advantages of E71T-1C over solid wire in B2B applications?

A: Key advantages include significantly higher deposition rates, better penetration, improved mechanical properties (especially impact toughness), and enhanced versatility for all-position welding, leading to reduced fabrication time and costs.

Q: How does the flux in E71T-1C interact with the shielding gas?

A: The flux in E71T-1C is specially formulated to work synergistically with the reactive CO2 e71t 1 shielding gas. It provides additional protection, deoxidizers, and alloying elements, enhancing arc stability, shaping the weld bead, and producing easily removable slag while ensuring optimal mechanical properties.

Conclusion

The E71T-1C gas shield flux coated welding wire, meticulously engineered to perform with its specified e71t 1 shielding gas, represents a cornerstone in modern industrial welding. Its ability to deliver high deposition rates, superior mechanical properties, and excellent weldability across all positions makes it an indispensable choice for critical applications in shipbuilding, heavy equipment manufacturing, structural fabrication, and petrochemical industries. By understanding its detailed manufacturing process, technical specifications, and the nuanced interaction with its shielding gas, B2B decision-makers can ensure optimized welding operations that lead to enhanced efficiency, reliability, and cost-effectiveness. Partnering with an authoritative and trustworthy vendor capable of providing consistent quality, technical expertise, and customized solutions further solidifies the foundation for successful project outcomes.

References

- American Welding Society. (2018). AWS A5.20/A5.20M: Specification for Carbon Steel Electrodes for Flux Cored Arc Welding. Miami, FL: American Welding Society.

- International Organization for Standardization. (2015). ISO 17632: Welding consumables - Tubular cored electrodes for gas shielded and non-gas shielded metal arc welding of non-alloy and fine grain steels - Classification. Geneva, Switzerland: ISO.

- Lincoln Electric. (2023). Understanding Flux-Cored Arc Welding (FCAW). Retrieved from [Generic industry resource or technical article link].

- Miller Electric Mfg. LLC. (2023). FCAW - Flux Cored Arc Welding Process. Retrieved from [Generic industry resource or technical article link].

- Esab Welding & Cutting Products. (2023). FCAW Welding Wire Selection Guide. Retrieved from [Generic industry resource or technical article link].

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025