feb. . 10, 2025 10:34

Back to list

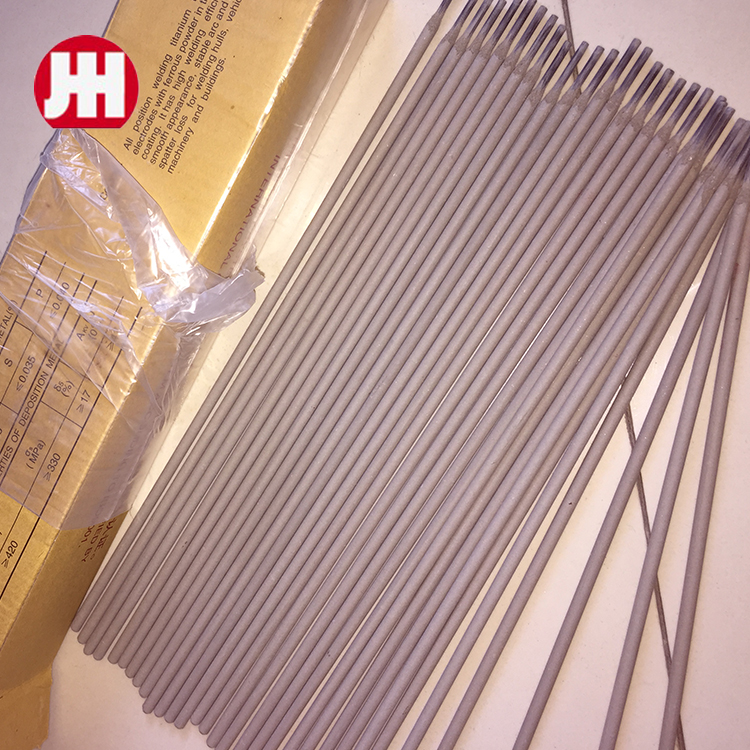

ER70S-6 Co2 Solid Mig Welding Wire

For professionals in the welding industry, the importance of selecting the right welding wire cannot be overstated. One of the most popular choices is the ER70S welding wire, known for its versatility and efficiency in various applications. This welding wire is a low-alloy, copper-coated wire commonly used for MIG welding. Here, we'll delve into the unique attributes of ER70S, shedding light on why it's an indispensable choice for welders seeking optimal outcomes.

In terms of ease of use, the ER70S wire provides an even and stable arc, which is particularly important for consistent weld quality. Novice welders and seasoned professionals alike appreciate its user-friendliness, which helps in minimizing defects such as spatter and undercut. Its forgiving nature means that even under less than ideal conditions, welders can achieve optimal results. Field experts consistently choose ER70S welding wire due to its proven track record in delivering strong, reliable welds. Its application ranges from automotive and construction to shipbuilding and pipeline work. Given its robustness and versatility, it’s no surprise that ER70S welding wire is a staple in these industries. Safety and trustworthiness are critical components when discussing welding equipment and materials. ER70S wires produced by reputable manufacturers adhere to rigorous quality control standards and industry specifications. This compliance ensures that the wire meets strict safety and performance standards, providing peace of mind and reliability to welders and engineers. In conclusion, the ER70S welding wire is more than just a choice—it's an integral part of welding excellence. Its high tensile strength, corrosion resistance, versatility in different gases, and ease of use make it a preferred option for numerous welding applications. Professionals seeking efficiency, durability, and quality should look no further than ER70S to meet and exceed their project requirements.

In terms of ease of use, the ER70S wire provides an even and stable arc, which is particularly important for consistent weld quality. Novice welders and seasoned professionals alike appreciate its user-friendliness, which helps in minimizing defects such as spatter and undercut. Its forgiving nature means that even under less than ideal conditions, welders can achieve optimal results. Field experts consistently choose ER70S welding wire due to its proven track record in delivering strong, reliable welds. Its application ranges from automotive and construction to shipbuilding and pipeline work. Given its robustness and versatility, it’s no surprise that ER70S welding wire is a staple in these industries. Safety and trustworthiness are critical components when discussing welding equipment and materials. ER70S wires produced by reputable manufacturers adhere to rigorous quality control standards and industry specifications. This compliance ensures that the wire meets strict safety and performance standards, providing peace of mind and reliability to welders and engineers. In conclusion, the ER70S welding wire is more than just a choice—it's an integral part of welding excellence. Its high tensile strength, corrosion resistance, versatility in different gases, and ease of use make it a preferred option for numerous welding applications. Professionals seeking efficiency, durability, and quality should look no further than ER70S to meet and exceed their project requirements.

Previous:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025