ian. . 14, 2025 11:26

Back to list

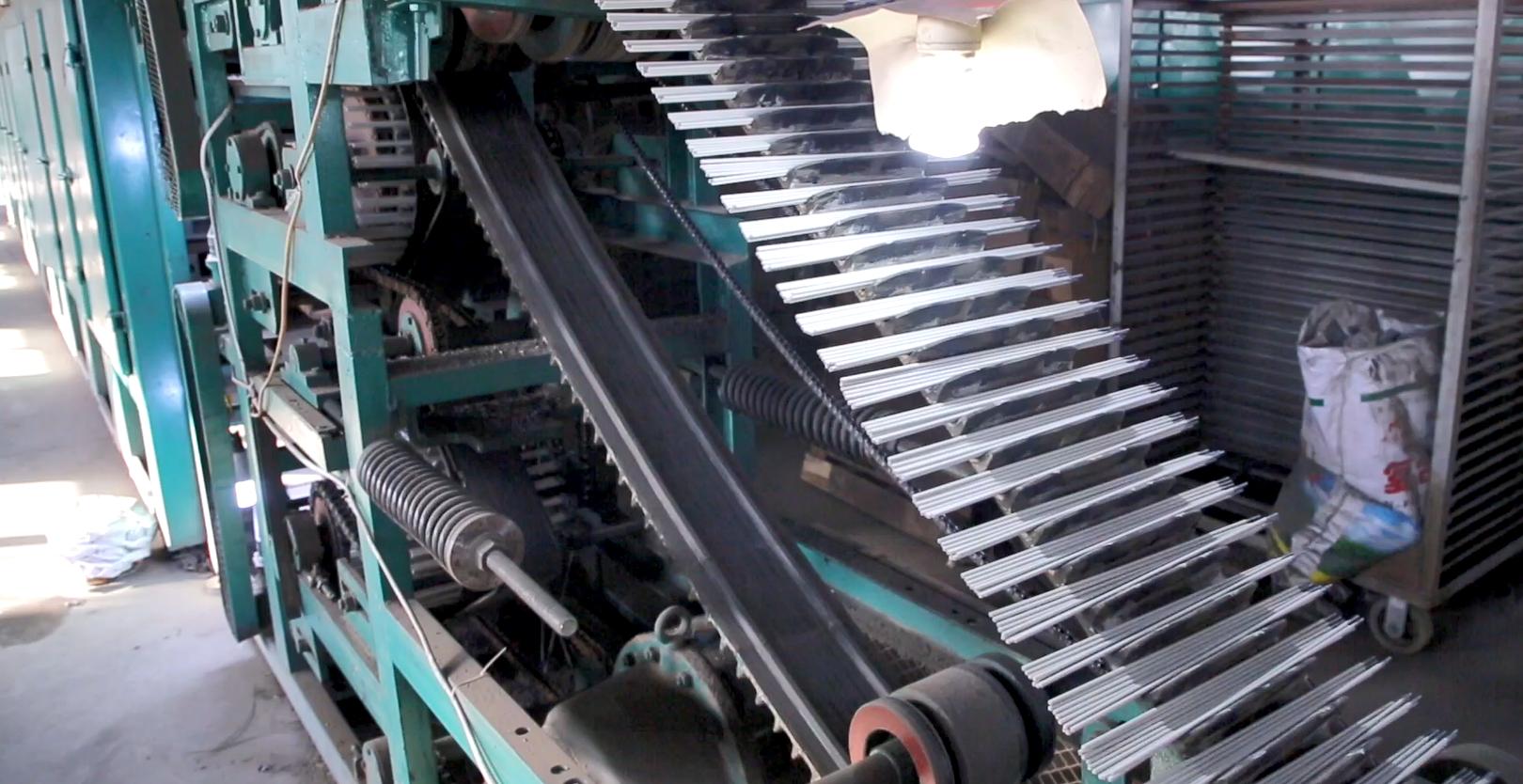

welding electrode e7018

The E7018 welding electrode is a staple in construction and fabrication industries, known for its reliable performance and versatility. Over a decade of using E7018 electrodes has given me firsthand insights into its strengths and best-use practices, insights that can greatly benefit professionals seeking to optimize their welding projects.

Welder expertise is a significant factor that enhances the results achievable with E7018 electrodes. These electrodes require a certain proficiency, demanding precise heat control and manipulation during the welding process. The electrode operates optimally within the 100-180 amp range, depending on the workpiece thickness. Skilled welders will appreciate the smooth arc performance and ease of slag removal, both of which contribute to cleaner welds and reduced post-weld cleanup. Safety is another domain where E7018 electrodes shine. Their reliability minimizes the number of defects that must be repaired, reducing overall exposure to the welding environment, which invariably includes fumes and UV radiation. Furthermore, using high-quality personal protective equipment (PPE) and maintaining a well-ventilated workspace mitigates health risks, ensuring safe welding practices with these electrodes. Finally, the cost-effectiveness of E7018 cannot be overlooked. Though typically higher-priced than some other electrodes, the reliability and reduced risk of defects translate into fewer repairs and rework. This means that the total cost of a project over its lifetime is often lower when using E7018, making it a financially sound choice for professionals committed to quality and durability. In conclusion, E7018 welding electrodes stand out in the field for their performance across diverse applications, especially where strength, durability, and safety are priorities. Proper handling and skilled implementation further enhance its benefits, making it a trusted choice among professionals aiming for excellence in weld quality.

Welder expertise is a significant factor that enhances the results achievable with E7018 electrodes. These electrodes require a certain proficiency, demanding precise heat control and manipulation during the welding process. The electrode operates optimally within the 100-180 amp range, depending on the workpiece thickness. Skilled welders will appreciate the smooth arc performance and ease of slag removal, both of which contribute to cleaner welds and reduced post-weld cleanup. Safety is another domain where E7018 electrodes shine. Their reliability minimizes the number of defects that must be repaired, reducing overall exposure to the welding environment, which invariably includes fumes and UV radiation. Furthermore, using high-quality personal protective equipment (PPE) and maintaining a well-ventilated workspace mitigates health risks, ensuring safe welding practices with these electrodes. Finally, the cost-effectiveness of E7018 cannot be overlooked. Though typically higher-priced than some other electrodes, the reliability and reduced risk of defects translate into fewer repairs and rework. This means that the total cost of a project over its lifetime is often lower when using E7018, making it a financially sound choice for professionals committed to quality and durability. In conclusion, E7018 welding electrodes stand out in the field for their performance across diverse applications, especially where strength, durability, and safety are priorities. Proper handling and skilled implementation further enhance its benefits, making it a trusted choice among professionals aiming for excellence in weld quality.

Previous:

Next:

Latest news

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025