Фев . 10, 2025 11:11

Back to list

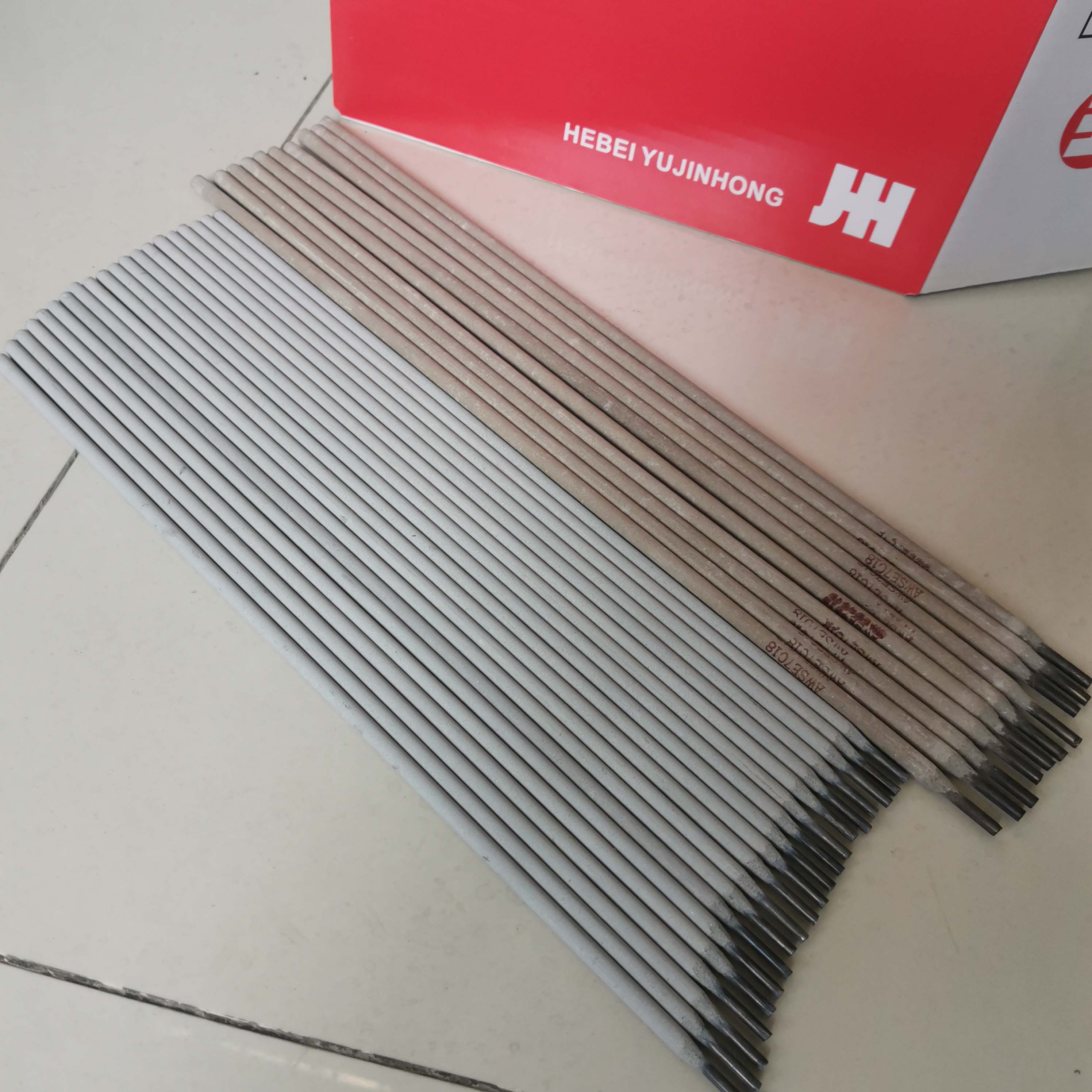

aluminum mig wire

Aluminum MIG wire is an essential component in the world of welding, offering a unique set of characteristics that make it ideal for a range of applications. The importance of selecting the right type of aluminum MIG wire cannot be overstated, as the choice impacts the quality, strength, and longevity of the final welds. In the realm of metal fabrication, understanding aluminum MIG wire's properties and applications reflects both technical expertise and industry authority.

Professional welders emphasize the importance of cleanliness when working with aluminum MIG wire. Even minor contamination can lead to defects in the weld, so surfaces must be thoroughly cleaned before welding. This attention to detail not only reflects expertise but also builds the trustworthiness of a craftsman or organization, as clean and strong welds are less likely to fail and result in costly repairs or safety issues. Trust in aluminum MIG wire products is often established through rigorous testing and certification. Reputable manufacturers subject their wires to stringent quality control processes to ensure consistency and reliability. This level of quality assurance positions a product as authoritative in the market, giving confidence to end-users that their selected wire will perform as expected in demanding applications. In the competitive arena of welding supplies, products that consistently demonstrate these principles of expertise, authoritativeness, and trustworthiness stand out. It's crucial for both manufacturers and suppliers to not only provide high-quality aluminum MIG wire but also to offer comprehensive support and guidance to their clients, ensuring optimal results for each specific welding project. In conclusion, aluminum MIG wire is an indispensable element in modern welding, offering flexibility and efficiency needed by various industries. By understanding its properties and the intricacies of its use, professionals can leverage its advantages to produce high-quality welds and establish a reputation for excellence. The real-world experiences, coupled with a commitment to quality, reinforce the critical role of aluminum MIG wire in achieving superior welding outcomes.

Professional welders emphasize the importance of cleanliness when working with aluminum MIG wire. Even minor contamination can lead to defects in the weld, so surfaces must be thoroughly cleaned before welding. This attention to detail not only reflects expertise but also builds the trustworthiness of a craftsman or organization, as clean and strong welds are less likely to fail and result in costly repairs or safety issues. Trust in aluminum MIG wire products is often established through rigorous testing and certification. Reputable manufacturers subject their wires to stringent quality control processes to ensure consistency and reliability. This level of quality assurance positions a product as authoritative in the market, giving confidence to end-users that their selected wire will perform as expected in demanding applications. In the competitive arena of welding supplies, products that consistently demonstrate these principles of expertise, authoritativeness, and trustworthiness stand out. It's crucial for both manufacturers and suppliers to not only provide high-quality aluminum MIG wire but also to offer comprehensive support and guidance to their clients, ensuring optimal results for each specific welding project. In conclusion, aluminum MIG wire is an indispensable element in modern welding, offering flexibility and efficiency needed by various industries. By understanding its properties and the intricacies of its use, professionals can leverage its advantages to produce high-quality welds and establish a reputation for excellence. The real-world experiences, coupled with a commitment to quality, reinforce the critical role of aluminum MIG wire in achieving superior welding outcomes.

Previous:

Next:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025