Янв . 09, 2025 11:32

Back to list

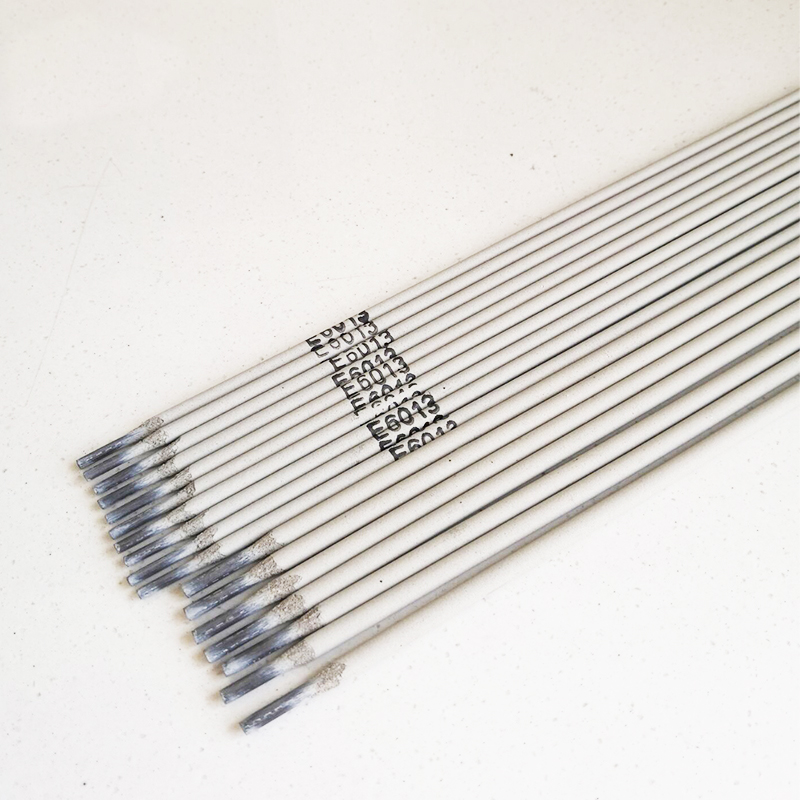

electrodos

Electrodes play a crucial role in various technological and medical applications, steadily capturing attention in diverse industries for their multifunctional properties. As technology advances, the need for efficient and reliable electrodes becomes increasingly apparent. This has compelled industry professionals and researchers to explore and develop electrodes that meet the ever-growing demands of precision and reliability.

Experts highlight that electrode manufacturing requires an understanding of electrochemistry, material science, and the specific requirements of each application. This specialized knowledge ensures that the electrodes produced meet the highest standards of precision and performance. Companies that excel in electrode innovation typically collaborate with academic institutions and research organizations to stay at the forefront of technological advances. Moreover, the credibility and trustworthiness in the electrode market are established through rigorous testing and quality assurance measures. Manufacturers are encouraged to adhere to international standards and certifications to ensure product safety and efficacy. This fosters consumer trust and establishes a brand as a reliable source of high-quality electrode products. Authoritative voices in the field emphasize that the future of electrodes looks promising with continued research and investment. Developing more sustainable and cost-effective production methods while minimizing environmental impact remains a priority. The push towards eco-friendly electrode solutions is not only ethically significant but also economically beneficial, given the increasing consumer shift towards environmental consciousness. In conclusion, the dynamic world of electrodes represents a blend of experience, expertise, and constant innovation. Staying informed about advancements in material science and manufacturing techniques is essential for businesses aiming to leverage the full potential of electrodes in their products. As industries evolve, the demand for diverse and sophisticated electrode solutions continues to grow, opening avenues for significant contributions to technological and medical advancements.

Experts highlight that electrode manufacturing requires an understanding of electrochemistry, material science, and the specific requirements of each application. This specialized knowledge ensures that the electrodes produced meet the highest standards of precision and performance. Companies that excel in electrode innovation typically collaborate with academic institutions and research organizations to stay at the forefront of technological advances. Moreover, the credibility and trustworthiness in the electrode market are established through rigorous testing and quality assurance measures. Manufacturers are encouraged to adhere to international standards and certifications to ensure product safety and efficacy. This fosters consumer trust and establishes a brand as a reliable source of high-quality electrode products. Authoritative voices in the field emphasize that the future of electrodes looks promising with continued research and investment. Developing more sustainable and cost-effective production methods while minimizing environmental impact remains a priority. The push towards eco-friendly electrode solutions is not only ethically significant but also economically beneficial, given the increasing consumer shift towards environmental consciousness. In conclusion, the dynamic world of electrodes represents a blend of experience, expertise, and constant innovation. Staying informed about advancements in material science and manufacturing techniques is essential for businesses aiming to leverage the full potential of electrodes in their products. As industries evolve, the demand for diverse and sophisticated electrode solutions continues to grow, opening avenues for significant contributions to technological and medical advancements.

Previous:

Next:

Latest news

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025