Rutile Welding Rods - Smooth Arc, Low Spatter, Clean Finish

Rutile Welding Rods is a key solution in the manufacturing industry, specifically within Fabricated metal products and And welding materials. This article explores how HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Rutile Welding Rods Overview

- Benefits & Use Cases of Rutile Welding Rods in And welding materials

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Rutile Welding Rods from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

Rutile Welding Rods Overview

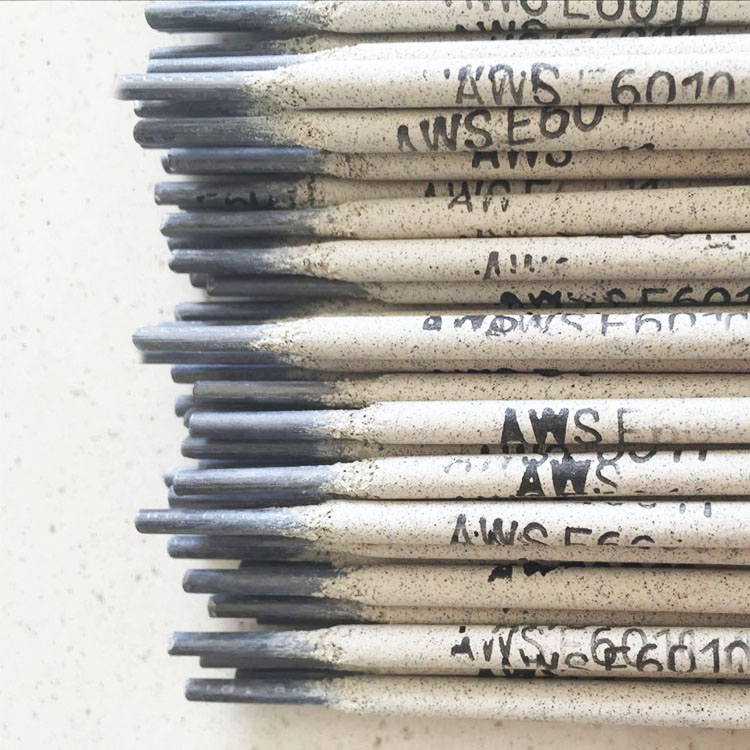

Rutile welding rods are SMAW electrodes formulated with a titanium dioxide (TiO2) rich coating. In daily production for Fabricated metal products and And welding materials, these electrodes are valued for their smooth, stable arc, minimal spatter, easy slag removal, and attractive bead profile. Typical rutile classifications (such as E6013/E7014 in the AWS A5.1 family) run on AC or DC, making them shop-friendly for varied power sources and positions. Common applications include thin-gauge mild steel, general fabrication, light structures, and aesthetically demanding cap passes.

B2B welding managers often pair rutile rods for fill and cap with a deep-penetrating root such as an aws e6010 electrode, especially in pipe spool and structural work. While AWS E6010 is a cellulosic type, its compatibility in multi-pass sequences with rutile electrodes helps balance penetration, speed, and finish. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. manufactures to AWS/ISO standards, supports WPS/PQR development, and offers lot traceability, consistent coating density, and moisture-resistant packaging—key factors for repeatable performance across shifts and sites. Procurement teams can expect standardized diameters, clear current ranges, and detailed mill test data to streamline approvals and audits.

Benefits & Use Cases of Rutile Welding Rods in And welding materials

In And welding materials workflows, rutile electrodes shine in sheet-metal fabrication, railings, brackets, light structural frames, and general repair. They offer easy re-strike, fluid but controllable slag, and clean bead appearance—reducing post-weld grinding and polishing. For multi-pass procedures, many shops use an aws e6010 root for fast-freezing penetration and follow with rutile rods for fill/cap to deliver both integrity and surface quality. This combination is common in tank and pipeline fabrication, OEM maintenance bays, and contract manufacturing where throughput and finish must coexist.

- Competitive advantages: stable arc on AC/DC, low spatter, easy slag removal, and visually consistent beads that reduce rework.

- Operator-friendly handling supports faster training curves and higher first-pass yield in mixed-skill teams.

- When paired with an aws e6010 electrode for roots, shops gain a proven, audit-ready procedure that balances speed, penetration, and aesthetics.

- HEBEI YUJINHONG TECHNOLOGY CO.,LTD. brings category expertise with consistent coating chemistry, tight dimensional control, and technical support to optimize parameters by diameter and position.

Cost, Maintenance & User Experience

Total cost of ownership for rutile welding rods hinges on arc efficiency, rework avoidance, and consumable consistency. Facilities report that rutile beads often require less post-weld cleanup versus general-purpose electrodes, freeing labor for higher-value tasks and improving takt times. In multi-pass work, using rutile rods for fill/cap after a root made with aws e6010 can cut overall cycle time by reducing grinding and touch-ups—critical in high-mix, deadline-driven shops. For procurement, predictable burn rates and minimized scrap are key levers for ROI.

- Durability and storage: keep cartons sealed until use; follow the manufacturer’s datasheet for storage humidity and recommended reconditioning for rutile types. Note that E6010 cellulosic types have different handling requirements than rutile rods—align with your WPS.

- User feedback from Fabricated metal products producers highlights smoother arc starts, fewer inclusions, and consistent bead appearance across shifts, simplifying QA and reducing inspection delays.

- HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports deployments with batch certificates, process guidance, and packaging options that protect coating integrity throughout global logistics.

Sustainability & Market Trends in manufacturing

Fabrication leaders face rising demands for cleaner operations, traceability, and regulatory adherence. Rutile welding rods, when used in well-ventilated, fume-controlled cells, help maintain predictable fume profiles and reduce downstream finishing—cutting energy and abrasives consumption. In parallel, many facilities standardize on procedures that pair rutile rods with aws e6010 for critical roots, meeting code while supporting throughput and consistent inspection outcomes. Market trends point to growing automation on fit-up and finishing steps, making stable, low-spatter electrodes a strategic consumable choice.

- Sustainability levers include recyclable packaging, optimized oven usage, and reduced rework. These reduce operational carbon intensity and total consumable waste.

- HEBEI YUJINHONG TECHNOLOGY CO.,LTD. positions itself as a forward-thinking partner with quality systems, responsible sourcing, and continuous improvement across coating lines and kilns—supporting both compliance and ESG reporting.

Conclusion on Rutile Welding Rods from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

For B2B decision makers in manufacturing, Rutile Welding Rods deliver a practical blend of arc stability, finish quality, and operator-friendly handling—ideal for Fabricated metal products and And welding materials. When paired with an aws e6010 root, your team can achieve robust penetration and a high-quality cap with fewer touch-ups. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. backs every shipment with dependable quality, documentation, and technical support to streamline qualification and production.

- Contact us: email: info@steeltoolschina.com

- Visit our website: https://www.steeltoolschina.com

- Explore our aws e6010 electrode page: AWS E6010 Welding Electrodes

-

What is a medium-frequency pulse? What types of welding are suitable for?ข่าวNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?ข่าวNov.21,2025

-

Welding Knowledge 6ข่าวNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?ข่าวNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?ข่าวNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016ข่าวNov.17,2025