Welding Rod 2.0 mm for Structural Welding - High Strength & Precision

Mobile: 0086-311-68035766

Email: info@steeltoolschina.com

Address: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA

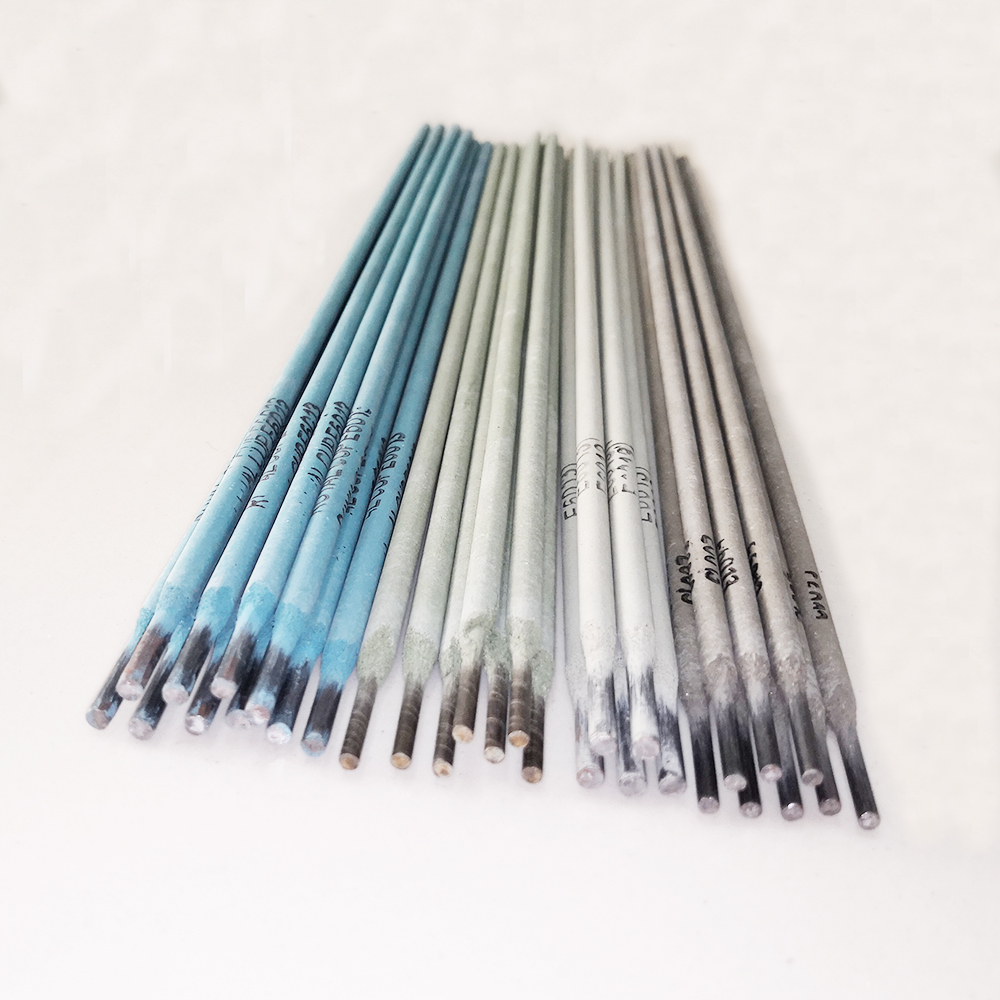

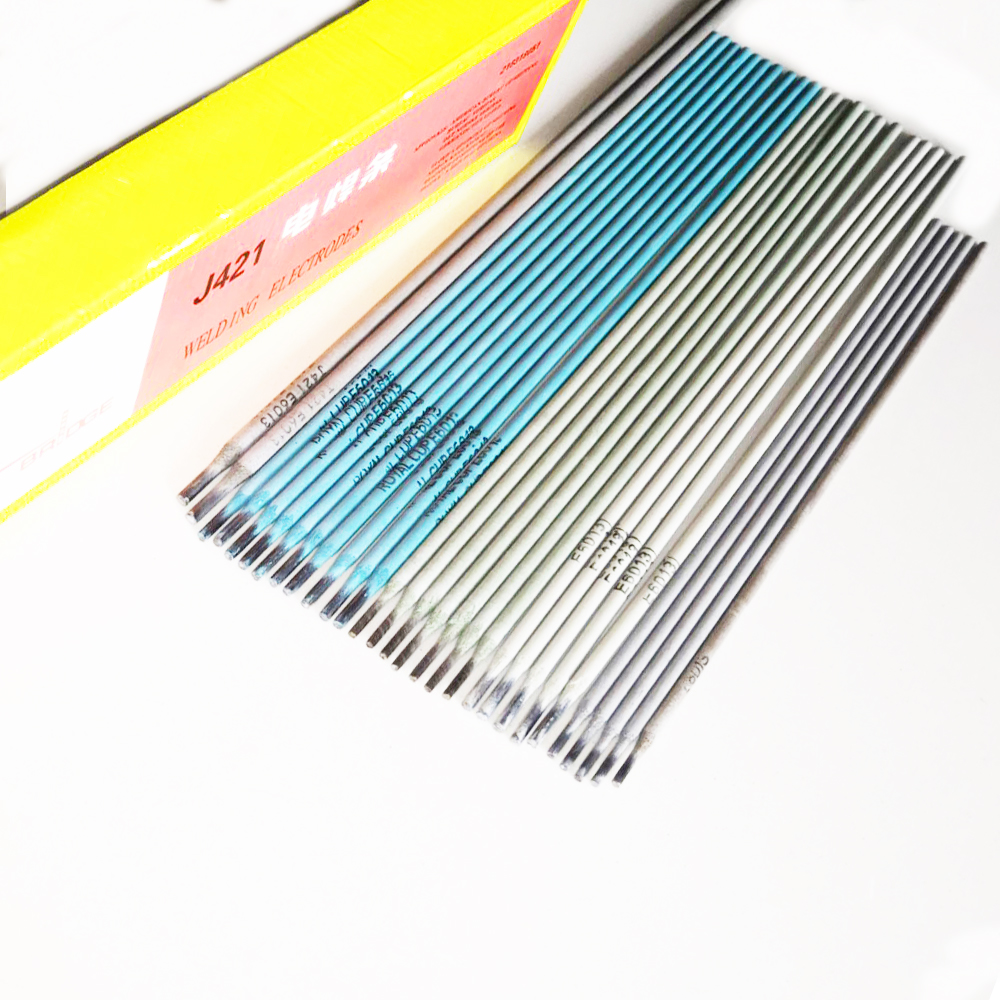

Product Overview: welding rod 2.0 mm - 2.0mm (5/64”) E6013 Welding Rod Electrodes Manufacture

The welding rod 2.0 mm, manufactured by HEBEI YUJINHONG TECHNOLOGY CO.,LTD., is one of the most sought-after products in structural welding applications. The 2.0mm (5/64”) E6013 Welding rod Electrodes Manufacture refers strictly to a 2.0mm iron core diameter, not including the coating thickness.

Regarding how thin the material can be welded with this rod, there is no official, universally accepted standard—making its practical range versatile for industries requiring fine yet robust welds.

See details at welding rod 2.0 mm product page.

Industry Trends in welding rod 2.0 mm and Structural Welding Rods

The market for welding rod 2.0 mm is expanding exponentially, especially in the construction, shipbuilding, and precision engineering sectors. New demands for thinner, stronger welds have led to continuing research and innovations, with E6013 rods setting the standard for all-position usability, arc stability, and slag control.

Trends indicate a surge in automated and robotic welding applications where 2.0mm rods are optimal for their manageable current range and adaptability to semi-thin base materials.

[Source]

Technical Parameter Overview of welding rod 2.0 mm

| Parameter | Value | Description |

|---|---|---|

| Rod Diameter | 2.0mm (5/64”) | Core size, not including coating |

| Standard | E6013 / AWS A5.1 | American Welding Society classification |

| Length | 300mm / 350mm (Varies) | Common factory-supplied lengths |

| Current Range | 40–60A (DC/AC) | Suggested for best arc stability |

| Tensile Strength | ≥430 MPa | Minimum mechanical strength after welding |

| Slag Type | Rutile (smooth removal) | Ensures easy clean up |

| Main Application | Sheet metal, structural welding, general fabrication | Versatility due to manageable size |

Main Technical Indicators Comparison of 2.0mm (5/64”) E6013 Welding rod Electrodes Manufacture

Key Applications of welding rod 2.0 mm and Structural Welding Rods

- Light and general fabrication where precision and slim welds are required

- Automotive body repair and small structure reinforcement

- Shipbuilding sub-assemblies, deck plate welding

- Construction of lightweight steel structures and trusses

- Machinery parts maintenance and patch welding

- Household steel item fabrication

- School and educational workshops (due to low current, easy handling)

EEAT Enhancement: Industry Authority & References

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. leverages advanced processes for product consistency and mechanical performance, in compliance with AWS A5.1 and ISO welding rod standards. Their R&D integrates input from international welding forums, and the company’s technical literature is regularly cited by Welding Journal (AWS).

Expert FAQ on welding rod 2.0 mm & Structural Welding Rods

A1: The core is typically low-carbon mild steel, optimized for versatility and ductility, with a rutile-based coating for arc stabilization.

A2: Industry standards include AWS A5.1, ISO 2560, and relevant national norms (GB/T 5117 in China), governing chemical, physical, and performance characteristics.

A3: Store in a dry, temperature-stable environment below 75% humidity. Preheating at 70-100°C for an hour can improve performance in humid climates.

A4: The rutile (titanium dioxide-based) coating ensures smooth slag release, minimal spatter, and controlled arc – ideal for welding thin to medium-thick sections.

A5: E6013 rods deliver optimal arc stability and minimal splatter on both AC and DC (straight/reverse polarity), but DC(+) often yields slightly deeper penetration.

A6: No strict standard, but experienced welders recommend a minimum of 1.5mm base thickness for clean, full-penetration welds with a welding rod 2.0 mm.

A7: Approx. 1.5–2.5g/min at the recommended current, with a deposition efficiency between 65–72% depending on arc length and operator skill.

Conclusion: Technical Excellence and Global Integration

The welding rod 2.0 mm product line from HEBEI YUJINHONG TECHNOLOGY CO.,LTD. embodies the cutting-edge standards for structural welding rods, guided by rigorous research, user feedback from top industry forums, and the authoritative standards of the American Welding Society. Reliability, usability, and adaptability ensure its presence in diverse application domains.

1. AWS Welding Journal. Latest Electrodes Performance Review

2. WeldingWeb – Welding Rods Application Forum. https://weldingweb.com/vbb/forumdisplay.php?2-General-Welding-Questions

3. ISO 2560:2020. Consumables for Manual Metal Arc Welding of Carbon and Carbon Manganese Steels.

4. AWS A5.1/A5.1M:2012 Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

5. China Welding Association (CWA): Chinese Welding Standards & Technology

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025