2.5 mm welding electrode manufacturers

Understanding 2.5mm Welding Electrode Manufacturers

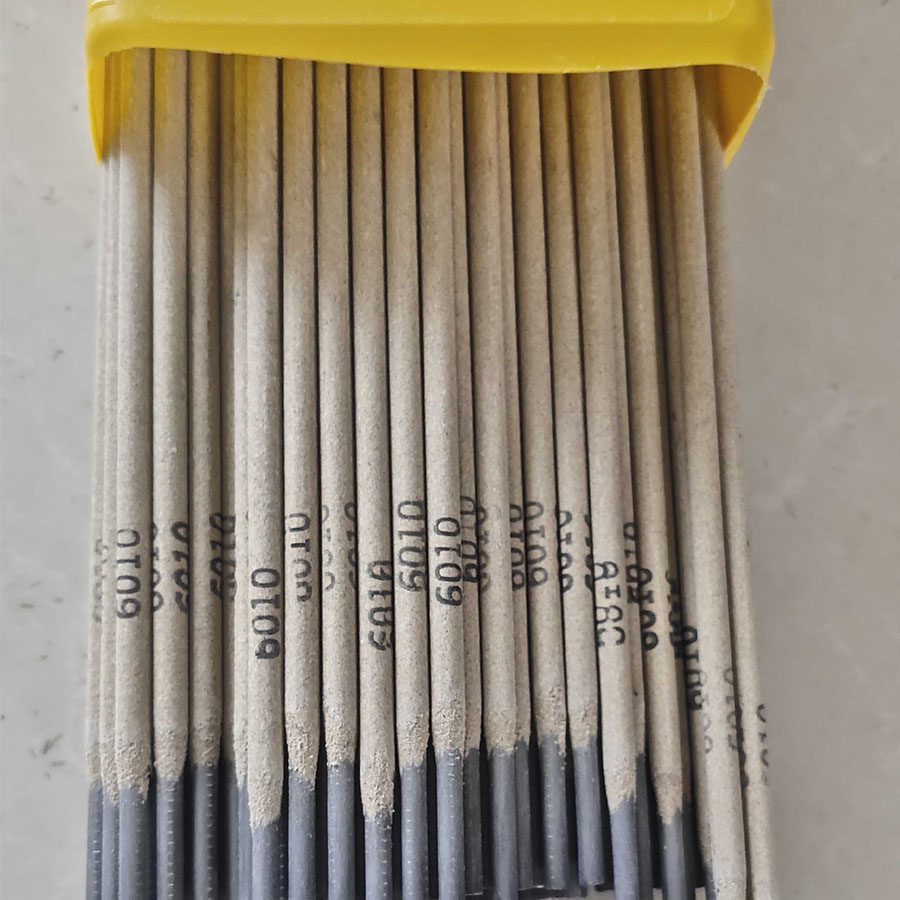

Welding is a crucial process in various industries, including construction, automotive, and manufacturing. Among the critical components of this process are welding electrodes, which serve as the filler material during welding operations. Among these, 2.5 mm welding electrodes are particularly popular due to their versatility and applicability in various welding tasks. This article explores the significance of 2.5 mm welding electrode manufacturers and the factors that influence their choice.

Importance of 2.5 mm Welding Electrodes

2.5 mm welding electrodes are widely used in manual arc welding processes, especially in situations requiring high precision and control. Their size makes them ideal for both thin and medium thickness materials, such as pipes, sheets, and plates commonly found in construction and repair work. These electrodes allow for a stable arc, excellent penetration, and a smooth finishing weld, making them valuable for both amateur and professional welders.

Key Considerations in Choosing Manufacturers

When selecting a manufacturer for 2

.5 mm welding electrodes, several factors come into play1. Quality of Materials The first and foremost criterion should be the quality of the raw materials used to produce the electrodes. High-quality electrodes provide better arc stability and less spatter, which leads to cleaner welds. Manufacturers should ideally comply with international standards, ensuring their products meet safety and performance criteria.

2.5 mm welding electrode manufacturers

2. Production Processes The manufacturing process plays a crucial role in determining the quality of the welding electrodes. Advanced technology and automated processes often result in higher quality products. It is essential to assess whether the manufacturer invests in the latest manufacturing technologies.

3. Types of Electrodes Different applications require different types of welding electrodes. Some manufacturers may specialize in specific types - such as mild steel, stainless steel, and cast iron electrodes - while others may offer a broader range. Depending on the type of welding projects, it’s vital to choose manufacturers that can supply the appropriate electrodes for specific applications.

4. Certification and Reputation A manufacturer’s reputation often reflects the quality of their products. Look for manufacturers with good customer feedback, industry certifications, and a proven track record in the welding community. Reliability and consistency in product quality are essential for successful welding operations.

5. Cost and Availability While quality is critical, so is cost-effectiveness. The ideal manufacturer balances quality with pricing, ensuring that welding electrodes are affordable without compromising performance. Additionally, consider the availability of the products; having a reliable supply chain is crucial for ongoing projects.

6. Customer Support and Service Efficient customer service can significantly enhance the overall experience with a manufacturer. A manufacturer that offers technical support, product consultations, and prompt response to queries can be a valuable partner in your welding projects.

Conclusion

The choice of a 2.5 mm welding electrode manufacturer is foundational for achieving successful welding outcomes. Quality materials, advanced production techniques, diverse product offerings, positive reputation, competitive pricing, and excellent customer support are all factors that welders should consider when making their selection. By choosing the right manufacturer, welders can ensure consistent, high-quality results that not only enhance their craftsmanship but also contribute to the overall success of their welding projects. As the demand for welding continues to rise across various sectors, so does the importance of selecting the right partners in electrode manufacturing.

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025

-

E7016 Welding Rods for Smooth, Low Hydrogen Welding PerformanceNewsJul.29,2025

-

E7016 Welding Rods for High Strength & Low Hydrogen WeldingNewsJul.29,2025