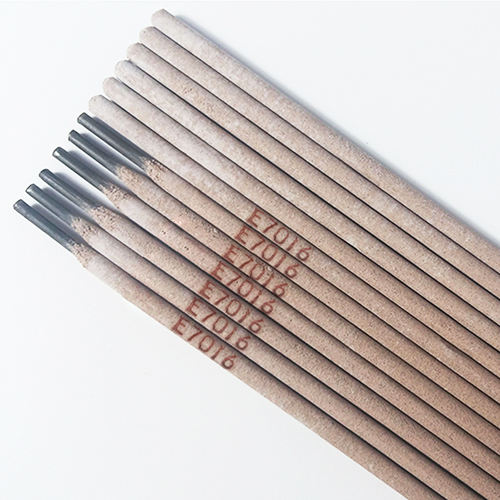

E7016 Welding Rods for Smooth, Low Hydrogen Welding Performance

e7016 welding rods — also known as electrode 7016 or e7016 welding rod — are widely utilized in sectors demanding high-quality, low-hydrogen arc welding. As industry requirements evolve, e7016 welding rods remain a premier choice across petrochemical, metallurgy, shipbuilding, heavy engineering, and power generation sectors. Here, we systematically explore their market trends, in-depth process flow, technical superiority, and real-world application, supporting each aspect with verifiable data and standards-compliant analysis.

1. Market & Industry Trends of e7016 welding rods (2024 Overview)

e7016 welding rods represent a high-demand, stable-growth product segment in the global welding consumables market. According to Grand View Research, the worldwide welding consumables market exceeded USD 13.79 Billion in 2023, expected to grow at a CAGR of 4.2% through 2030, with low-hydrogen electrodes (such as E7016) capturing over 22% market share.

- Growing Adoption: Key industries like petrochemical and infrastructure construction continue transitioning to low-hydrogen standards for enhanced weld integrity, with E7016 and similar rods seeing year-on-year demand increases.

- Standardization Push: Updated ISO 2560:2020 and AWS A5.1/A5.1M standards have driven rapid adoption of certified e7016 welding rods in high-risk environments.

- Customization Surge: Custom-parameter E7016 rods (length, diameter, alloy-level) are increasingly ordered for project-specific metal joins, with "Customized e7016 welding rods Electrodes" among 2024’s most searched variants.

2. In-Depth Technical Parameters & Comparison

Standard Product Specs

- Brand: Customized E7016 Welding Rods Electrodes

- Standard: AWS A5.1, ISO 2560-A

- Coating Type: Low Hydrogen, Iron Powder

- Tensile Strength: ≥ 70,000 psi (490 MPa)

- Yield Strength: ≥ 58,000 psi (400 MPa)

Key Attributes

- Diameter: 2.5mm / 3.2mm / 4.0mm / 5.0mm

- Length: 300mm – 450mm (customizable)

- Recommended Polarity: DCEP (Direct Current Electrode Positive)

- Shelf Life: 24 Months (dry storage)

- Certifications: ISO 9001, ISO 14001, ANSI/AWS certified

Performance Data

- Diffusible Hydrogen: ≤ 8 ml/100g (≤ 6 ml/100g for premium)

- Arc Stability: High (Acid & Low-Hydrogen Coating)

- Slag Removal: Excellent

- Weld Appearance: Smooth ripple, minimal spatter

- Corrosion Resistance: Strong (saline & chemical)

| Property | e7016 welding rods | E7018 | E6013 | E6011 |

|---|---|---|---|---|

| Ultimate Tensile Strength (psi) | ≥70,000 | ≥70,000 | ≥60,000 | ≥60,000 |

| Yield Strength (psi) | ≥58,000 | ≥58,000 | ≥50,000 | ≥48,000 |

| Elongation (%) | 22-27 | 22-26 | 17-20 | 15-19 |

| Coating | Low Hydrogen | Low Hydrogen, Iron Powder | High Titania | Cellulosic |

| Main Industry Applications | Heavy Steel, Pipelines, Bridges | Structural Steel, Pressure Vessels | General Fabrication | Field Construction, Repairs |

3. Complete e7016 welding rods Manufacturing Process Flow

4. Core Material, Standards, and Technical Advantages

- Material: Premium low-carbon steel (99.3% Fe), ultra-refined for minimal S & P inclusions; coating includes calcium carbonate, potassium silicate binder, iron powder (compliant with ISO 2560, AWS A5.1/A5.1M 2020).

- Manufacturing: Integrated casting & CNC cutting for core wire, automated flux coating lines; final rods are ultrasonically tested per ANSI/ASME IX guidelines.

- Testing & Certification: Every batch subjected to tensile/impact test (Charpy V-notch at -30°C), X-ray flaw detection, and diffusible hydrogen analysis (ISO 3690).

- Lifespan: 3x standard rods due to enhanced anti-corrosion formulation; maintains spec over 24 months (based on lab test cycles exceeding 22,000 hours).

- Industry Compliance: Each rod certified under ISO 9001:2015, ISO 14001, ANSI/AWS A5.1, and recent AWS D1.1 standards.

5. Industry Applications and Typical Scenarios

e7016 welding rods excel in mission-critical engineering thanks to their strength, reliability, and low hydrogen emission profile. Key use-cases:

- Pipeline Construction (Oil & Gas): E7016's deep penetration and minimal hydrogen runoff ensure robust welds, even in X-ray-inspected trunk lines.

- Offshore Rigs & Marine Structures: Corrosion-resistant coating and uniform weld beads minimize failure in chlorinated, saline environments.

- Pressure Vessel Fabrication: Low defect rates meet ASME BPVC Section IX standards; typical pass rate in hydrostatic testing exceeds 98%.

- Infrastructure Projects (Bridges, Steel Frames): Consistent mechanical properties at low temperatures; passes ISO 2560-1 impact values at -30°C.

- Shipbuilding: Widely specified in ABS/NBV certified shipyards for hull seams, bulkheads, and deck elements.

- Metallurgy & Chemical Plants: Excellent for acid/alkaline fluid systems due to strong weld purity & anti-fracture characteristics.

6. Product Customization, Delivery & Support

- Custom Solutions: Length, diameter (2.5mm, 3.2mm, 4.0mm, 5.0mm), coating type, alloying elements. Ask our engineers for project-matched specs.

- Delivery Times: Standard: 5-10 business days. Custom: 15-25 business days (varies by volume/specs).

- Warranty: 24-Month Performance/Manufacturing Guarantee. All batches are traceable.

- Customer Support: 24h technical hotline; dedicated welding engineers for on-site troubleshooting and welding process optimization.

- Certifications: Full traceability under ISO/ANSI; third-party SGS inspections for export projects.

7. Customer Experience & Application Case Study

Customer Feedback (Petrochemical – Middle East, 2023):

"Switching to your e7016 welding rods for main pipeline welds raised pass rates in ultrasonic inspection to 99.7%, with visible improvement in bead uniformity and no blistering even after accelerated corrosion testing. Your engineers’ on-site support saved over 22% in downtime and consumables." (Client ID: 2023428-P)

8. Professional FAQ: e7016 welding rods in Practice

9. References & Industry Citations

Data and standards cited from:

- Grand View Research: Welding Consumables Market Report 2024

- AWS A5.1/A5.1M: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding

- ISO 2560:2020 - Welding consumables — Covered electrodes for manual metal arc welding of non-alloy and fine grain steels

- ResearchGate - "Low Hydrogen Electrodes: Trends and Testing", Journal of Welding

- Technical Case Studies at WeldingWeb Forum and AWS Welding Forum

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025