Feb . 07, 2025 02:35

Back to list

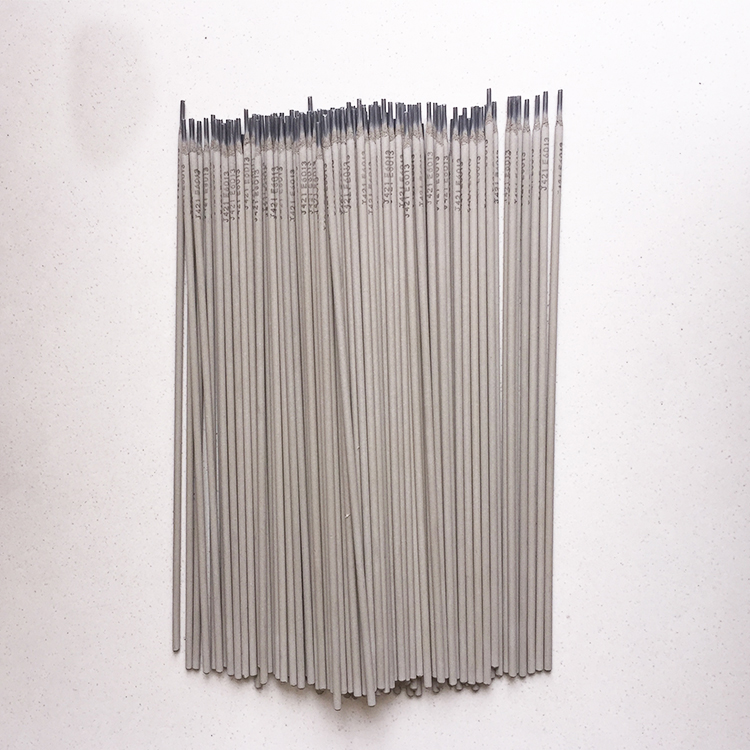

carbon steel welding wire

Unlocking the full potential of 308L welding wire can dramatically improve the quality and durability of stainless steel projects. This welding wire, specially formulated for superior performance in joining stainless steel, has become indispensable in industries ranging from food processing to chemical equipment production. As a seasoned welding expert, I have accrued vast experience with different welding wires, but 308L stands out for its exemplary properties and performance.

Moreover, industries reliant on stainless steel, like the aerospace or food and beverage sectors, often require compliance with stringent hygienic and safety protocols. The 308L welding wire aligns with these demands, preventing cross-contamination and ensuring robust, non-reactive welds that stand up to rigorous cleaning processes. When choosing 308L welding wire, one must consider not just the purchasing decision but also factors affecting cost efficiency and waste reduction. Its excellent feedability makes it economically appealing—reducing waste, minimizing rework, and cutting down labor costs. Businesses evaluating long-term investments will find that the higher initial cost of 308L wire pays dividends in operational efficiency and reduction of imperfections that could incur costly repairs down the line. Finally, trustworthiness arises from the direct feedback and success stories shared by professionals in the field. Numerous welders have reported heightened satisfaction with 308L for its flawless finish and reliable performance. This is backed by data from field tests showing outstanding resistance to weld cracking and corrosion resistance, even under the most demanding conditions. In conclusion, 308L welding wire is not merely a consumable but an integral part of effective stainless steel work. Its user-centric design, compatible chemistry with stainless steels, and consistent performance make it a trusted ally for professionals aiming for excellence and reliability. Transitioning to or exclusively using 308L wire can substantially elevate the quality and longevity of your stainless steel welds, reflecting a clear expertise in executing stainless steel projects.

Moreover, industries reliant on stainless steel, like the aerospace or food and beverage sectors, often require compliance with stringent hygienic and safety protocols. The 308L welding wire aligns with these demands, preventing cross-contamination and ensuring robust, non-reactive welds that stand up to rigorous cleaning processes. When choosing 308L welding wire, one must consider not just the purchasing decision but also factors affecting cost efficiency and waste reduction. Its excellent feedability makes it economically appealing—reducing waste, minimizing rework, and cutting down labor costs. Businesses evaluating long-term investments will find that the higher initial cost of 308L wire pays dividends in operational efficiency and reduction of imperfections that could incur costly repairs down the line. Finally, trustworthiness arises from the direct feedback and success stories shared by professionals in the field. Numerous welders have reported heightened satisfaction with 308L for its flawless finish and reliable performance. This is backed by data from field tests showing outstanding resistance to weld cracking and corrosion resistance, even under the most demanding conditions. In conclusion, 308L welding wire is not merely a consumable but an integral part of effective stainless steel work. Its user-centric design, compatible chemistry with stainless steels, and consistent performance make it a trusted ally for professionals aiming for excellence and reliability. Transitioning to or exclusively using 308L wire can substantially elevate the quality and longevity of your stainless steel welds, reflecting a clear expertise in executing stainless steel projects.

Previous:

Next:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025