Feb . 02, 2025 05:13

Back to list

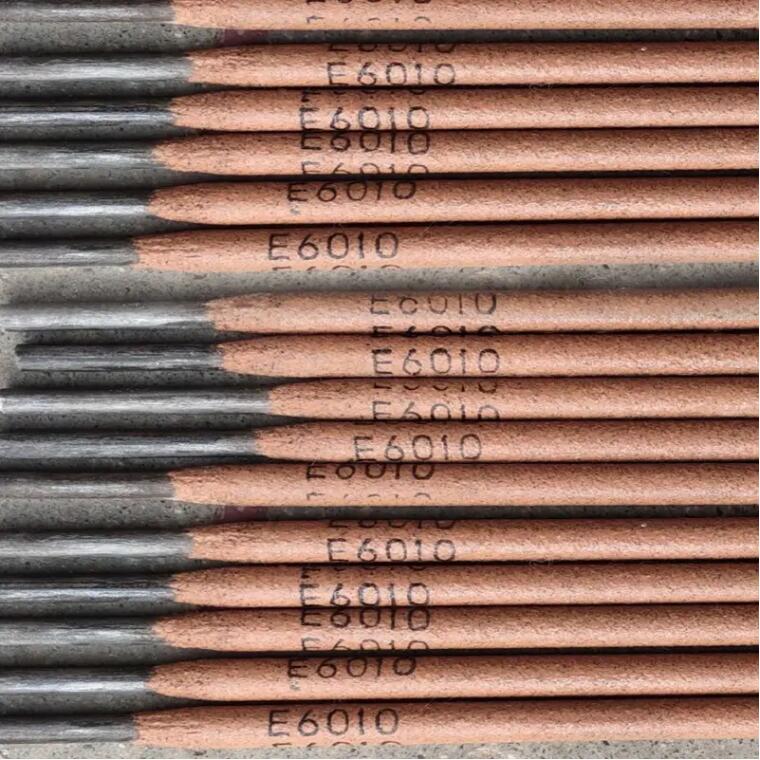

E6013 Welding Electrode Rods for carbon steel

Electrode stick welding, also known as Shielded Metal Arc Welding (SMAW), remains an essential process in the welding industry due to its versatility and cost-effectiveness. As a cornerstone technique, it’s crucial for welders, both novice and experienced, to understand its nuances for efficient and successful project completion.

Authoritative voices in the industry, including certified welding inspectors and experienced metallurgists, stress safety measures and proper handling of electrodes, as these factors are heavily linked to the success of the weld and the safety of the operator. Using the correct protective gear, ensuring good ventilation, and enrolling in competency training courses are vital steps that underscore the trustworthiness and credibility of any welding operation. Furthermore, trust in the equipment and maintenance practices holds significant weight. Regular checks on welding machines for correct amperage and clean connections, alongside electrode storage in dry conditions to avoid moisture pick-up that could lead to hydrogen-induced cracking, are key practices endorsed by professionals. Welders looking to incorporate innovation into their stick welding processes should consider hybrid approaches, integrating new technology insights, like digital meters for monitoring weld parameters in real-time. Staying attuned to technological advancements not only enhances process efficiency but also aligns with evolving industry standards. In conclusion, electrode stick welding’s standing in the welding community is a testament to its robust capabilities and ease of use. Engaging in continuous education, hands-on experience, and adherence to best practices in safety and equipment management sets a solid foundation for welding excellence. By embracing these principles, welders can expect improved results, leading to successful projects and enhanced career opportunities in an ever-evolving industry.

Authoritative voices in the industry, including certified welding inspectors and experienced metallurgists, stress safety measures and proper handling of electrodes, as these factors are heavily linked to the success of the weld and the safety of the operator. Using the correct protective gear, ensuring good ventilation, and enrolling in competency training courses are vital steps that underscore the trustworthiness and credibility of any welding operation. Furthermore, trust in the equipment and maintenance practices holds significant weight. Regular checks on welding machines for correct amperage and clean connections, alongside electrode storage in dry conditions to avoid moisture pick-up that could lead to hydrogen-induced cracking, are key practices endorsed by professionals. Welders looking to incorporate innovation into their stick welding processes should consider hybrid approaches, integrating new technology insights, like digital meters for monitoring weld parameters in real-time. Staying attuned to technological advancements not only enhances process efficiency but also aligns with evolving industry standards. In conclusion, electrode stick welding’s standing in the welding community is a testament to its robust capabilities and ease of use. Engaging in continuous education, hands-on experience, and adherence to best practices in safety and equipment management sets a solid foundation for welding excellence. By embracing these principles, welders can expect improved results, leading to successful projects and enhanced career opportunities in an ever-evolving industry.

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025