J421 Electrodes Effective Welding Solutions for Diverse Metal Applications

Understanding J421 Electrode Welding A Comprehensive Overview

Welding is an essential process in manufacturing and construction, enabling the joining of materials to create robust structures and components. Among the various welding methods, the use of electrodes plays a pivotal role, and one of the most widely utilized types is the J421 electrode. This article delves into the specifics of J421 electrode welding, its applications, advantages, and considerations.

What is J421 Electrode Welding?

J421 refers to a specific type of coated electrode used in arc welding, particularly within the manual metal arc (MMA) welding processes. The J421 electrode is classified as a versatile and reliable option, particularly for welding low-alloy and carbon steels. The designation 'J421' follows the norms set by the American Welding Society (AWS), where J denotes the type of coating and 421 indicates the specific characteristics of the electrode.

Composition and Characteristics

The J421 electrode typically consists of a core wire surrounded by a coating that aids in stabilizing the arc, protecting the weld from oxidation, and providing additional alloying elements to improve mechanical properties. The coating is primarily made of cellulosic materials, which contribute to a smooth, stable arc and produce a gas shield around the molten weld pool, preventing contamination from the atmosphere.

This electrode is designed to be used with direct current (DC) and is commonly utilized in horizontal, flat, or even overhead positions, showcasing a good degree of versatility. The 421 designation indicates a balanced chemistry, ensuring sound mechanical properties and decent impact resistance in the completed welds.

Applications of J421 Electrode Welding

The versatility and reliability of J421 electrodes make them suitable for various applications in numerous industries. From fabricating structural components in construction to repairing machinery in manufacturing facilities, J421 electrodes can be employed in numerous situations. Common applications include

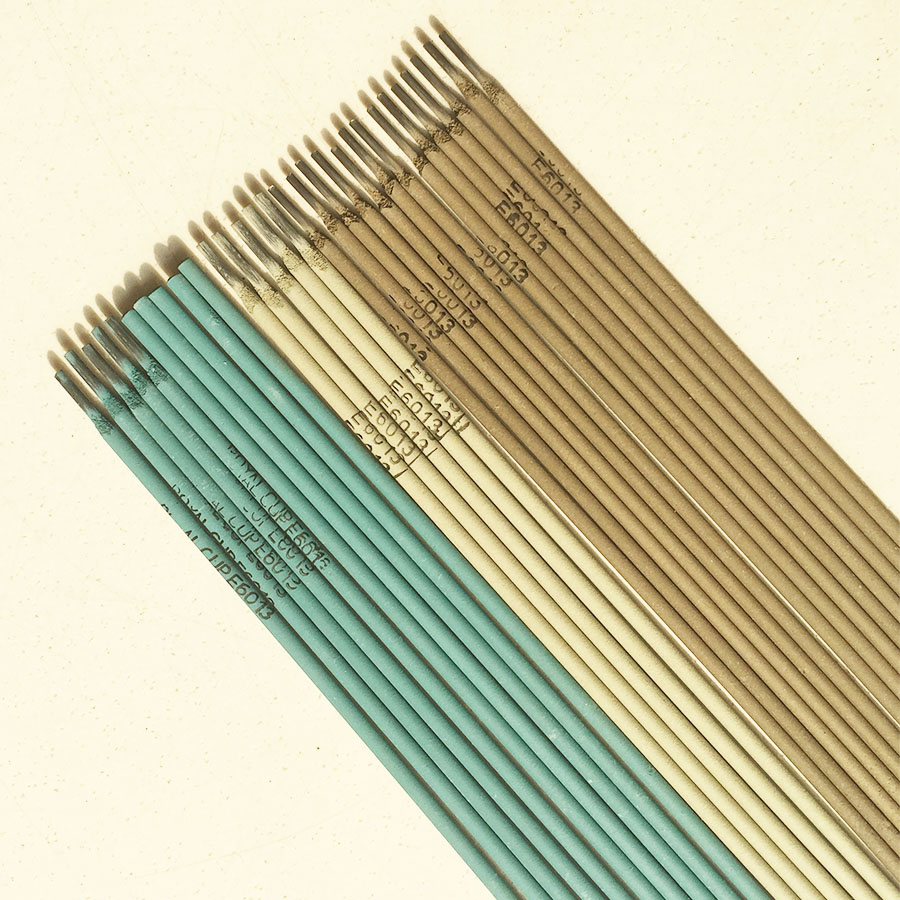

j421 electrode welding

1. Structural Welding J421 is frequently used for fabricating and reinforcing structural steel components, such as beams, columns, and frames. 2. Manufacturing It is common in manufacturing processes involving machinery, equipment parts, and heavy-duty components due to its excellent penetration and fusion capabilities. 3. Repair Works The ability to produce strong, durable welds makes J421 an ideal choice for repair and maintenance tasks, especially on steel structures that face fatigue or wear over time.

Advantages of J421 Electrode Welding

J421 electrode welding presents numerous advantages, which contribute to its popularity

1. Ease of Use The electrode is user-friendly, allowing even those with moderate skill levels to achieve satisfactory results. 2. Good Penetration J421 electrodes are known for their deep penetration, producing strong and reliable welds that can withstand significant stresses. 3. Versatility in Positions The electrode performs well in various welding positions, making it suitable for a wide range of applications. 4. Affordable J421 electrodes are often cost-effective, making them an attractive option for businesses looking to maintain quality without inflating their operational costs.

Considerations When Using J421 Electrodes

While the J421 electrode is a robust choice for many welding tasks, certain considerations should be kept in mind

1. Preparation of Base Metals Surface cleanliness is crucial for achieving strong bonds. Base materials should be free of dirt, rust, and paint. 2. Welding Environment Though J421 electrodes can handle a variety of conditions, extreme weather or windy environments may require additional management to protect the weld area. 3. Skill Level While the J421 is user-friendly, operators must still possess a fundamental understanding of welding techniques to maximize the quality of welds.

Conclusion

In summary, J421 electrode welding represents a pivotal method in the welding industry, combining versatility, reliability, and ease of use. Its applications span across various sectors, making it a preferred choice among professionals. By understanding the properties, advantages, and best practices of using J421 electrodes, welders can enhance their skills and ensure quality in their projects. The ongoing development and innovation in welding technology will only solidify the importance of J421 and similar electrodes in the future of welding.

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025

-

E7016 Welding Rods for Smooth, Low Hydrogen Welding PerformanceNewsJul.29,2025