Jan . 16, 2025 03:12

Back to list

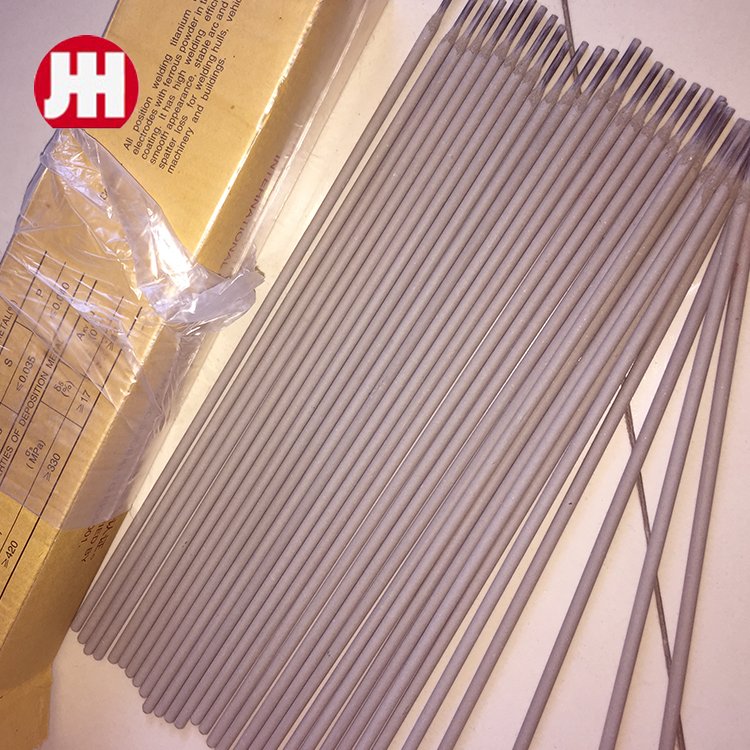

mig solid welding wire

MIG/MAG welding wire holds a pivotal role in the field of modern metal fabrication. While often the unsung hero behind sturdy constructions and intricate metal works, understanding the specifics of MIG (Metal Inert Gas) and MAG (Metal Active Gas) welding wires can elevate the quality of your projects considerably. This comprehensive guide sheds light on the nuances and significance of selecting the right welding wire tailored to both novice and professional needs.

Operational efficiency is undeniably influenced by the skill and experience of the welder. Expertise in understanding wire feed speed, voltage settings, and the precision of electrode angle becomes the linchpin for achieving seamless welds. Advanced welders often utilize synergic settings in modern machines, which automatically adjust parameters based on detected wire size and type, fortifying the dependability and excellence of the welding process. Trust plays a crucial role in the branding of welding wire products, which is why industry certification and adherence to global standards are non-negotiable. Purchasing from reputable manufacturers certified by bodies like the American Welding Society (AWS) or the ISO assures consistency in wire diameter, chemical composition, and overall performance. Moreover, thorough documentation accompanying these certifications provides an additional layer of reliability for professionals who depend on precision and repeatability in their work environment. The authority of knowledge in welding lies in implementing a proactive approach toward continuous learning and adapting to technological advancements in welding techniques. Investing time in training sessions, attending workshops, and conducting controlled experiments with different wire-gauge combinations pay dividends in the form of improved craftsmanship and project outcomes. Summing up, MIG/MAG welding wires are not merely consumables; they are the lifeblood of any metalworking project. Effective selection and application lead to structurally sound, aesthetically pleasing, and durable welds that stand testament to one’s experience, expertise, and dedication to quality. Trust the process, lean into authoritative sources for materials, and let informed choices drive your projects to unprecedented heights.

Operational efficiency is undeniably influenced by the skill and experience of the welder. Expertise in understanding wire feed speed, voltage settings, and the precision of electrode angle becomes the linchpin for achieving seamless welds. Advanced welders often utilize synergic settings in modern machines, which automatically adjust parameters based on detected wire size and type, fortifying the dependability and excellence of the welding process. Trust plays a crucial role in the branding of welding wire products, which is why industry certification and adherence to global standards are non-negotiable. Purchasing from reputable manufacturers certified by bodies like the American Welding Society (AWS) or the ISO assures consistency in wire diameter, chemical composition, and overall performance. Moreover, thorough documentation accompanying these certifications provides an additional layer of reliability for professionals who depend on precision and repeatability in their work environment. The authority of knowledge in welding lies in implementing a proactive approach toward continuous learning and adapting to technological advancements in welding techniques. Investing time in training sessions, attending workshops, and conducting controlled experiments with different wire-gauge combinations pay dividends in the form of improved craftsmanship and project outcomes. Summing up, MIG/MAG welding wires are not merely consumables; they are the lifeblood of any metalworking project. Effective selection and application lead to structurally sound, aesthetically pleasing, and durable welds that stand testament to one’s experience, expertise, and dedication to quality. Trust the process, lean into authoritative sources for materials, and let informed choices drive your projects to unprecedented heights.

Previous:

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025