Feb . 10, 2025 09:38

Back to list

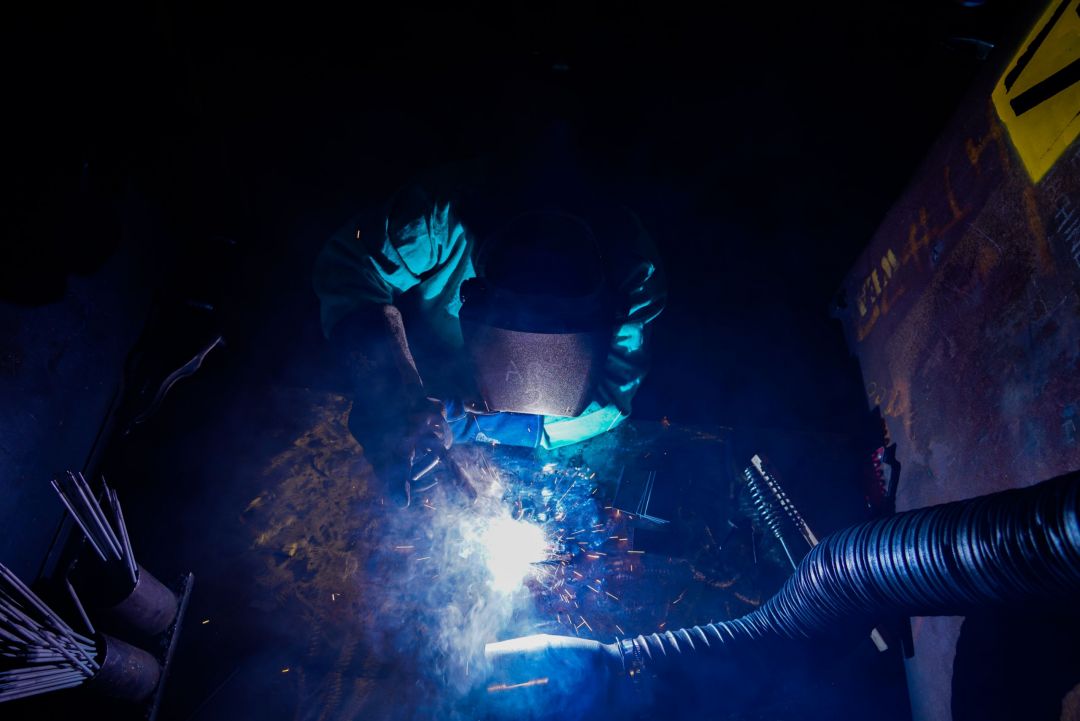

welding wire 030

Welding wire .030 is an essential component for those who delve into the intricate world of welding, offering both hobbyists and professionals the flexibility and reliability necessary for successful metal fabrication projects. Understanding its nuances can greatly enhance the quality and consistency of welds, making it a subject of interest for anyone serious about welding.

.030 welding wire also presents a degree of adaptability that is hard to match. While primarily used in MIG welding, it exhibits a proficiency that encourages experimentation and skill development among new welders. Whether used in crafting new metal furniture, undertaking an automotive restoration, or even building structural frameworks, its ease of use boosts confidence and competence. Expert welders often advocate for .030 wire because it enables learners to focus on refining their technique rather than battling against challenging wire dynamics. Moreover, the economic aspect of using .030 welding wire cannot be overlooked. Its status as a standard in the welding community ensures competitive pricing and widespread availability, factors that are crucial for both large scale operations and small workshops aiming to manage costs effectively without compromising on quality. The consistent performance, paired with cost-efficiency, makes it a staple in ensuring that quality workmanship can be delivered time and again, reinforcing its authoritative standing in the welding field. Finally, trustworthiness, the bedrock of all welding operations, is a testament to the reliability exhibited by .030 welding wire. Its integration in projects known for demanding precision and durability is a clear indicator of its capacity to meet high industry standards. Expert recommendations always point towards the .030 variant whenever projects call for light to medium-duty welding solutions. The collective endorsement from seasoned professionals and industry veterans establishes its credibility and solidifies its position as a key asset in a welder's toolkit. In conclusion, .030 welding wire is more than just a tool—it's an investment into precision, reliability, and versatility in welding practices. Whether you are looking to create something new or repair the old, its strength lies in its ability to deliver consistent, high-quality results. For anyone in the welding domain, recognizing the capabilities and benefits of .030 welding wire is not just useful, but indispensable in honing both skills and outcomes in work.

.030 welding wire also presents a degree of adaptability that is hard to match. While primarily used in MIG welding, it exhibits a proficiency that encourages experimentation and skill development among new welders. Whether used in crafting new metal furniture, undertaking an automotive restoration, or even building structural frameworks, its ease of use boosts confidence and competence. Expert welders often advocate for .030 wire because it enables learners to focus on refining their technique rather than battling against challenging wire dynamics. Moreover, the economic aspect of using .030 welding wire cannot be overlooked. Its status as a standard in the welding community ensures competitive pricing and widespread availability, factors that are crucial for both large scale operations and small workshops aiming to manage costs effectively without compromising on quality. The consistent performance, paired with cost-efficiency, makes it a staple in ensuring that quality workmanship can be delivered time and again, reinforcing its authoritative standing in the welding field. Finally, trustworthiness, the bedrock of all welding operations, is a testament to the reliability exhibited by .030 welding wire. Its integration in projects known for demanding precision and durability is a clear indicator of its capacity to meet high industry standards. Expert recommendations always point towards the .030 variant whenever projects call for light to medium-duty welding solutions. The collective endorsement from seasoned professionals and industry veterans establishes its credibility and solidifies its position as a key asset in a welder's toolkit. In conclusion, .030 welding wire is more than just a tool—it's an investment into precision, reliability, and versatility in welding practices. Whether you are looking to create something new or repair the old, its strength lies in its ability to deliver consistent, high-quality results. For anyone in the welding domain, recognizing the capabilities and benefits of .030 welding wire is not just useful, but indispensable in honing both skills and outcomes in work.

Previous:

Next:

Latest news

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025