Şub . 15, 2025 07:34

Back to list

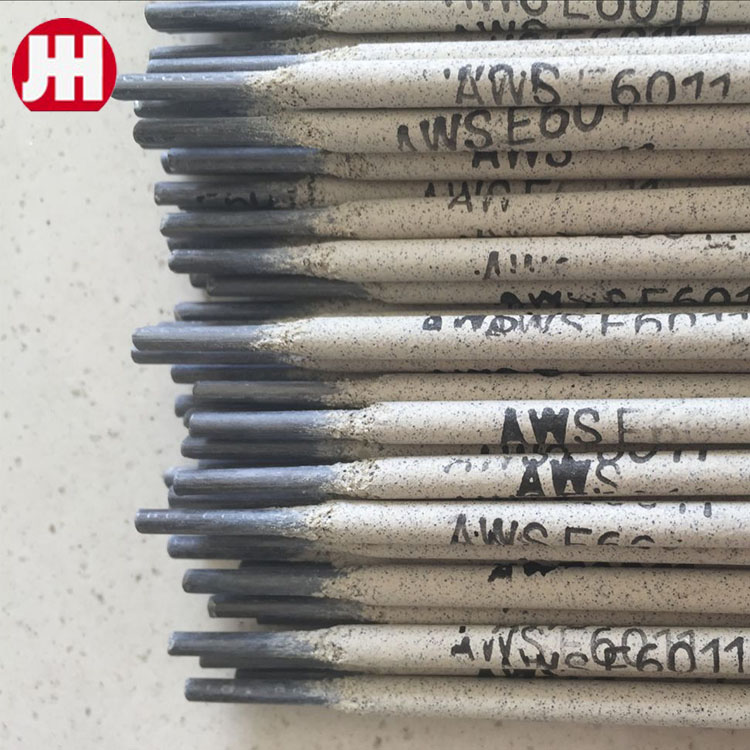

Carbon Steel Submerged Arc Welding Wire

For professionals in the welding industry, the necessity of selecting high-quality materials is paramount. Wholesale arc copper welding wire stands out as a crucial component for ensuring optimal performance and reliability in welding projects. Here's an exploration of why this product is indispensable, touching upon relevant experience, expertise, authoritativeness, and trustworthiness factors.

Authoritativeness in this domain is further supported by the industry's trust in copper as a reliable element in welding materials. Top industry standards frequently incorporate copper components due to their corrosion resistance, which is pivotal for projects exposed to harsh weather conditions or corrosive substances. The presence of copper in welding wires not only ensures stronger welds but also guarantees longevity, making it a preferred choice for professionals looking to uphold rigorous industry standards. Trustworthiness among wholesale suppliers is another aspect that cannot be overlooked. When sourcing arc copper welding wire, it's essential to partner with reputed wholesalers who can provide consistent, certified quality in their products. Verifiable certifications and adherence to quality control measures should be a baseline requirement for suppliers aiming to build long-term relationships within the industry. For clients, confidence in their source means fewer interruptions in the supply chain and prevents potential setbacks caused by subpar materials. Welders understanding the dynamic requirements of modern construction and repair projects are increasingly prioritizing copper welding wire. The blend of reliable performance, cost-saving potential, and the technical advantages it provides speaks to its position as a cornerstone in welding equipment. Wholesale purchasing not only ensures an ample supply for ongoing projects but also empowers businesses to leverage competitive pricing advantages, a strategic necessity in today's competitive market. In summary, the choice of wholesale arc copper welding wire represents a fusion of advanced material science and practical industry expertise. For experienced welders and procurement specialists, prioritizing such materials aligns with the broader objectives of operational efficiency, safety, and project excellence. For those navigating the complexities of welding in demanding environments, copper welding wire is more than just a component; it is an investment in quality and performance for present and future applications.

Authoritativeness in this domain is further supported by the industry's trust in copper as a reliable element in welding materials. Top industry standards frequently incorporate copper components due to their corrosion resistance, which is pivotal for projects exposed to harsh weather conditions or corrosive substances. The presence of copper in welding wires not only ensures stronger welds but also guarantees longevity, making it a preferred choice for professionals looking to uphold rigorous industry standards. Trustworthiness among wholesale suppliers is another aspect that cannot be overlooked. When sourcing arc copper welding wire, it's essential to partner with reputed wholesalers who can provide consistent, certified quality in their products. Verifiable certifications and adherence to quality control measures should be a baseline requirement for suppliers aiming to build long-term relationships within the industry. For clients, confidence in their source means fewer interruptions in the supply chain and prevents potential setbacks caused by subpar materials. Welders understanding the dynamic requirements of modern construction and repair projects are increasingly prioritizing copper welding wire. The blend of reliable performance, cost-saving potential, and the technical advantages it provides speaks to its position as a cornerstone in welding equipment. Wholesale purchasing not only ensures an ample supply for ongoing projects but also empowers businesses to leverage competitive pricing advantages, a strategic necessity in today's competitive market. In summary, the choice of wholesale arc copper welding wire represents a fusion of advanced material science and practical industry expertise. For experienced welders and procurement specialists, prioritizing such materials aligns with the broader objectives of operational efficiency, safety, and project excellence. For those navigating the complexities of welding in demanding environments, copper welding wire is more than just a component; it is an investment in quality and performance for present and future applications.

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025