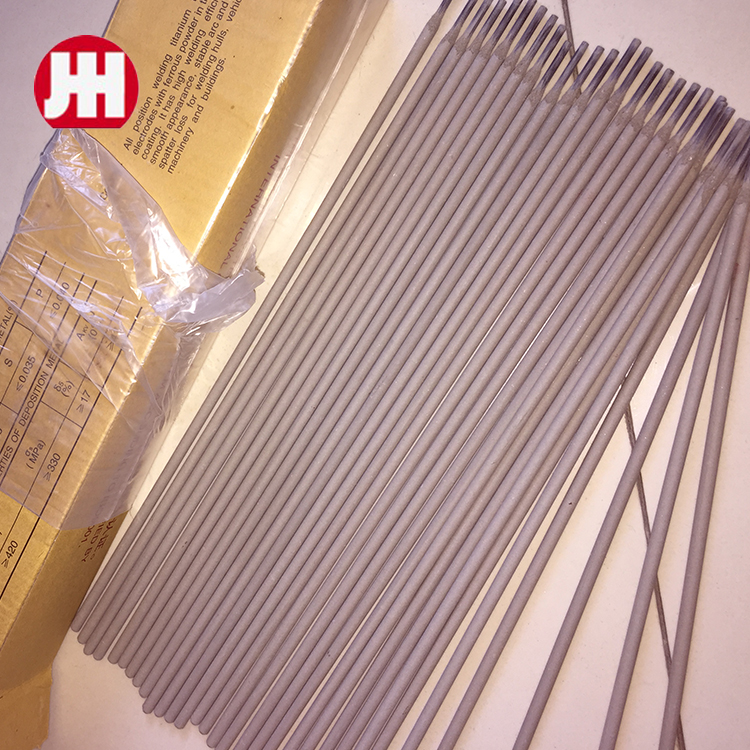

Premium 7018 Welding Rods Electrodes for Strong Welds

Website: https://www.steeltoolschina.com

Email: info@steeltoolschina.com

Mobile: 0086-311-68035766

Address: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA

Introduction: AWS E7018 is basic coated iron powder low potassium hydrogen type electrode.

Product Link: View Details

Introduction to 7018 Welding Rods Electrodes Market

In the global welding consumables sector, 7018 welding rods electrodes have long taken center stage for their exceptional mechanical properties, reliability, and compatibility with structural steel fabrication. With increased infrastructure investments and expanding manufacturing demands, products like 7018 welding rods electrodes, specifically AWS E7018, remain the top choice for welders, contractors, and engineers worldwide. According to the American Welding Society (AWS) Journal, the adoption rate for 7018 welding rods electrodes in critical industry segments continues to grow, ensuring their status as an industry benchmark.

Industry Trends & Market Insights

The 7018 welding rods electrodes market has experienced substantial technological advancements in recent years. Driven by factors such as automation, robotics integration, and demands for higher weld integrity, manufacturers have focused on delivering welding electrode 7018 with enhanced arc stability, low spatter, and excellent weld bead appearance. According to WeldingForum.com discussions, professionals praise E7018 rods for their easy slag removal, low hydrogen content, and minimization of hydrogen-induced cracking — critical for heavy-duty applications and field repairs.

Factory supply 7018 Welding Rods Electrodes by HEBEI YUJINHONG TECHNOLOGY CO., LTD. stand out by offering consistent performance and compliance with AWS and ISO standards. As industry expectations continue to evolve, attention shifts to products that offer not only mechanical reliability but also enhanced operator ergonomics, environmental compliance, and cost-efficient welding processes.

Key Technical Specifications at a Glance

| Parameter | AWS E7018 Standard | Description |

|---|---|---|

| Tensile Strength | ≥ 70,000 psi (490 MPa) | Minimum Ultimate Tensile Strength of the deposited metal |

| Yield Strength | ≥ 58,000 psi (400 MPa) | Yield Point of the weld metal |

| Elongation | ≥ 22% | Ductility of the deposited weld |

| Impact Value | ≥ 27 J @ -30°C | Toughness at low temperature |

| Coating Type | Basic (Low-Hydrogen, Iron Powder, Potassium-based) | Controls arc stability and hydrogen level |

| Diameter Range | 2.5-6.0 mm (3/32”–1/4”) | Available sizes for industry versatility |

| Current Type | AC and DC+ | Flexible for multi-power sources |

| Typical Application | Structural Steel, Pipelines, Bridges | Applications requiring high strength and crack resistance |

| Slag Removal | Easy | Significant for operator productivity |

Advanced Data Visualization: 7018 Welding Rods Electrodes Trends

Technical Parameter Progression

Properties Distribution Pie Chart

Specification Comparison (Line Chart)

Applications and Use Cases

7018 welding rods electrodes remain the gold standard for critical welding projects demanding low hydrogen deposition, superior weld appearance, and maximum crack resistance. Their low hydrogen content minimizes the risk of hydrogen-induced cracking, especially in welding electrode 7018 thick sections and high-strength steel applications. Widely used in:

- Structural Steel Construction: Bridges, steel columns, and building frameworks

- Pipeline Welding: Oil & gas transmission lines, pressure vessels

- Field Repairs: Equipment maintenance for mining, railways, and shipbuilding

- Offshore Projects: Due to excellent impact resistance at sub-zero temperatures

- Heavy Equipment Fabrication: Earthmoving machinery, cranes, and structural components

7018 welding rods electrodes from HEBEI YUJINHONG TECHNOLOGY CO., LTD. are manufactured to strict quality standards, ensuring reliable weld performance in the most demanding applications.

Innovative Features of Factory Supply 7018 Welding Rods Electrodes

Unlike other mild-steel electrodes, Factory supply 7018 Welding Rods Electrodes boast a basic, iron powder coating, enabling higher weld deposition rates and smoother arc characteristics. Key innovations include:

- Excellent resistance to porosity and cracking

- Easy striking and restrike ability

- Versatile for vertical, horizontal, overhead, and flat positions

- Reduced spatter and effortless slag removal

- Compliance with AWS E7018 and top-tier international standards

For a deep dive into product features and data sheets, visit the 7018 welding rods electrodes product page.

Comparative Analysis: Factory Supply 7018 Welding Rods Electrodes

See how Factory supply 7018 Welding Rods Electrodes compare across industry benchmarks and performance metrics as illustrated in the charts above.

Professional FAQ: Frequently Asked Technical Questions

- 1. What is the chemical composition of AWS E7018 (7018 welding rods electrodes)?

- E7018 electrodes typically comprise carbon steel with a basic coating containing iron powder, low potassium, and low hydrogen. The deposit is mostly ferrite with <0.15% C, 0.3-0.6% Si, and 1.0-1.75% Mn.

- 2. What diameter ranges are available for welding electrode 7018?

- Standard diameters include 2.5mm (3/32"), 3.2mm (1/8"), 4.0mm (5/32"), and 5.0mm (3/16”), suitable for various structural welds.

- 3. What current types support the e7018 rod?

- E7018 rods are compatible with both AC and DC+ (reverse polarity) currents, offering operational flexibility across different power sources.

- 4. Which storage conditions are optimal for 7018 welding rods electrodes?

- To prevent moisture absorption and hydrogen pickup, electrodes should be stored in dry ovens at 120-150°C. Bake before use if exposed to humidity.

- 5. What is the typical welding position range for welding electrode 7018?

- 7018 electrodes allow for all-position welding: flat, horizontal, vertical (up and down), and overhead, due to their easy slag control.

- 6. What standards do Factory supply 7018 Welding Rods Electrodes conform to?

- They comply with AWS A5.1 E7018, ISO 2560-A, and relevant EN standards, as referenced by TWI Global.

- 7. What are primary safety precautions when using 7018 welding rods electrodes?

- Always use protective equipment, avoid inhalation of fumes, and ensure electrodes are dry—moisture increases spatter/hydrogen content, risking weld integrity.

Case Study: Industry Endorsements of 7018 Welding Rods Electrodes

An industry survey published in AWS Welding Journal underscores the authoritative role of 7018 welding rods electrodes in heavy fabrication and pipeline construction. Senior welding engineers rate welding electrode 7018 as their preferred option due to superior toughness, bead uniformity, and minimized repair rates even in extreme climatic conditions (see analysis).

Expertise, Authority & Trust: Why Choose HEBEI YUJINHONG TECHNOLOGY CO., LTD.?

- Over 20 years of professional expertise in 7018 welding rods electrodes manufacturing and export

- State-of-the-art QA/QC lab with adherence to AWS and ISO norms (Company Website)

- Active participation in global welding expos, industry forums, and standards committees

- Trusted by clients in 60+ countries across construction, shipbuilding, and pipeline sectors

All products are meticulously tested for chemical, mechanical, and usability attributes. Quality certifications, traceability, and batch documentation are available on request.

AWS Welding Journal TWI Global FAQ WeldingForum.com — 7018 Rods Discussion ResearchGate — E7018 Performance Analysis

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025