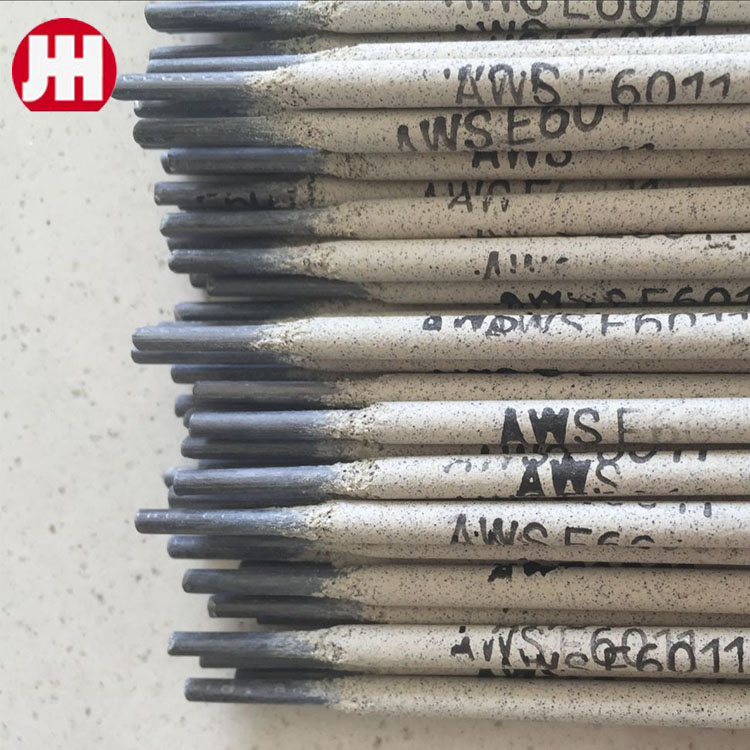

Top E6011 Electrode: All-Position AC/DC Welding Rod

Discovering Excellence: Top Welding Rod and Welding Wire Manufacturers from China at the Canton Fair

The Canton Fair stands as an unparalleled beacon in the global trade landscape, a formidable platform where innovation meets opportunity, and industry leaders showcase the vanguard of manufacturing prowess. For B2B decision-makers and procurement specialists in the industrial sector, this event is more than just a trade show; it's a strategic gateway to accessing cutting-edge technology and high-quality industrial hardware. When it comes to essential consumables like welding rod and зварювальний дріт, the Canton Fair consistently highlights manufacturers who are defining global standards, particularly from the powerhouse of China.

The demand for superior welding solutions—be it robust e6011 electrode for all-position welding or versatile welding wire for automated systems—is at an all-time high. The fair provides a unique vantage point to evaluate suppliers, forge invaluable partnerships, and secure products that drive efficiency and performance in diverse industrial applications. It underscores the critical role China plays in supplying the global market with advanced and cost-effective welding consumables, making it an indispensable event for anyone serious about their supply chain.

Industry Trend Spotlight: Navigating the Evolving Landscape of Industrial Tools

The industrial tools sector, encompassing everything from heavy machinery components to precision зварювальний дріт, is undergoing a profound transformation. Manufacturers and buyers alike are increasingly recognizing the imperative for tools that offer more than just basic functionality. Today, the market demands high-durability, ergonomically designed hand tools that minimize operator fatigue and maximize productivity. There's a growing push towards the integration of smart features, enabling proactive maintenance scheduling, real-time usage tracking, and even predictive analytics for optimal performance and extended tool life.

Innovation in materials science is also a major driver. The use of advanced alloys is leading to the development of industrial tools that are significantly lighter yet demonstrably stronger, capable of withstanding extreme conditions and delivering superior results. This is particularly relevant for specialized applications, where tools like a high-performance e 6011 welding rod must combine robust strength with precise handling characteristics. Furthermore, a growing emphasis on precision and automation compatibility is reshaping tool design, ensuring seamless integration into modern, automated manufacturing processes. These trends are not just buzzwords; they represent fundamental shifts that are gaining global attention and driving investment across the supply chain.

Market Dynamics: Growth, Challenges, and Opportunities

The global industrial tools market is projected for steady growth, a trajectory underpinned by several key macroeconomic factors. Renewed infrastructure spending initiatives across various continents are creating substantial demand for robust and reliable tools. Simultaneously, the continued manufacturing sector expansion, particularly in emerging economies, is fueling an insatiable need for a wide array of industrial consumables and equipment. Developing economies, in particular, are seeing significant industrialization, translating into increased demand across the board.

The accelerating pace of digitalization and automation in manufacturing is another powerful catalyst, driving demand for highly specialized tools that can interface with robotic systems and smart production lines. This includes precise зварювальний дріт solutions tailored for automated welding applications. However, the market is not without its complexities. Supply chain resilience and raw material price volatility remain key considerations for B2B buyers, necessitating strategic sourcing and robust inventory management.

Emerging Focus Areas for Smart Sourcing

- Global Sourcing for Industrial Tools: Diversifying supplier bases to mitigate risks and leverage competitive pricing, with a keen eye on emerging manufacturing hubs.

- Supply Chain Diversification: Moving beyond single-source reliance to build more resilient and adaptable supply networks.

- Quality Assurance and Compliance: Heightened scrutiny on product standards, certifications, and consistency, especially for critical items like e6011 electrode.

- Advanced Material Applications: Exploring tools and consumables made from novel materials that offer superior performance characteristics.

- Smart Manufacturing Integration: Tools that are designed to be part of an interconnected, data-driven production environment.

Profiles of Leading Companies: Pioneers in Welding and Industrial Hardware

HEBEI YUJINHONG TECHNOLOGY CO.,LTD.: A Chinese Powerhouse

Among the distinguished exhibitors at the Canton Fair, HEBEI YUJINHONG TECHNOLOGY CO., LTD. consistently stands out as a formidable player in the global industrial tools and hardware market. This Chinese enterprise has carved a significant niche through its specialization in a wide range of steel and hardware tools, delivering unparalleled quality and value to B2B clients worldwide. Their extensive product portfolio includes not only essential general-purpose tools but also highly specialized welding consumables like premium e6011 electrode and various types of зварювальний дріт, crucial for diverse industrial applications.

What sets HEBEI YUJINHONG TECHNOLOGY CO.,LTD. apart are its strong manufacturing capabilities, leveraging advanced production lines and stringent quality control protocols to ensure every product meets international standards. As a leading Chinese exporter, they offer highly competitive pricing without compromising on performance, making them an attractive partner for global procurement. Their commitment extends to an established global distribution network, ensuring timely and efficient delivery of their products to customers across continents. A core tenet of their philosophy is a steadfast focus on product durability and performance for industrial applications, understanding that reliability is paramount in demanding operational environments. Whether it's the consistent arc and penetration of their e 6011 welding rod or the feedability of their various зварювальний дріт, their products are engineered for excellence.

Explore HEBEI YUJINHONG's Quality Welding Electrodes

For detailed specifications and further product information on the e6011 electrode and other welding solutions, visit their official product page: HEBEI YUJINHONG TECHNOLOGY CO.,LTD. Product Page

The Global Landscape of Industrial Tool Manufacturing

While Chinese manufacturers like HEBEI YUJINHONG TECHNOLOGY CO.,LTD. are making significant strides, the broader industrial tools market is also shaped by the continued innovation and global presence of established global tool manufacturers such as Stanley Black & Decker, Bosch, and Makita. These giants have long been synonymous with quality and a vast array of industrial solutions, continuously investing in R&D to push the boundaries of tool technology, from advanced power tools to specialized зварювальний дріт and associated equipment.

Beyond these household names, the Canton Fair also brings into focus numerous other specialized steel tool manufacturers and exporters from industrial hubs like China, Taiwan, and India. These companies often offer niche products, innovative designs, or particularly cost-effective solutions for specific industrial requirements. Their presence underscores the diverse and dynamic nature of global manufacturing, providing B2B buyers with an extensive pool of options to meet their distinct operational needs for everything from a reliable e 6011 welding rod to comprehensive industrial tool kits.

Market Outlook & Opportunities: Charting the Future of Industrial Tools

Looking ahead, the industrial tools market is poised for exciting developments, driven by fundamental shifts in global manufacturing paradigms. The upcoming trends and buyer demand are heavily influenced by a collective push towards smarter, more efficient, and more sustainable industrial practices.

The Triple Mandate: Automation, Smart Manufacturing, and Sustainability

- Automation and Robotics: The increasing adoption of robotic systems in manufacturing necessitates tools and consumables designed for precision, consistency, and minimal human intervention. For the welding sector, this translates into a higher demand for advanced зварювальний дріт and automated welding rod feeding systems, optimized for seamless integration with robotic arms.

- Smart Manufacturing and Industry 4.0: The convergence of physical and digital technologies means that industrial tools are no longer isolated units. They are becoming connected, generating data that can be analyzed for process optimization, predictive maintenance, and enhanced operational efficiency. Tools with embedded sensors and IoT capabilities will see accelerated demand.

- Sustainability and Green Practices: Environmental responsibility is no longer optional. Buyers are increasingly seeking industrial tools and consumables manufactured through sustainable processes, with reduced waste and lower carbon footprints. This includes demand for energy-efficient welding equipment and consumables like e6011 electrode produced with environmentally conscious methods. Durability and reparability also play a crucial role in reducing consumption and waste.

For businesses, these trends represent significant opportunities. Investing in tools that align with these future-forward paradigms not only ensures operational competitiveness but also positions companies as leaders in a rapidly evolving industrial landscape.

Buyer/Business Takeaways: Strategic Sourcing for Success

For B2B decision-makers, strategic sourcing is paramount. The Canton Fair offers a concentrated opportunity to apply these strategic approaches, especially when it comes to critical consumables like welding rod and зварювальний дріт.

Why Investing in Quality Welding Consumables Makes Business Sense

- Enhanced Project Quality: Superior зварювальний дріт and e6011 electrode ensure stronger, more reliable welds, reducing rework and improving end-product quality.

- Operational Efficiency: High-quality consumables lead to consistent performance, smoother operations, and less downtime due to material failures or equipment issues.

- Cost Savings in the Long Run: While initial costs might vary, the extended lifespan of tools and the reduced need for repairs and replacements due to better welding quality translate into significant long-term savings.

- Worker Safety and Ergonomics: Investing in ergonomically designed tools and reliable consumables contributes to a safer working environment and reduces operator fatigue.

Tips for Adopting or Partnering with Chinese Manufacturers

- Thorough Due Diligence: Research potential partners extensively, verify certifications (e.g., ISO, CE), and check references. Canton Fair is an ideal place for initial vetting.

- Clear Communication & Specifications: Provide precise technical specifications for products like e 6011 welding rod. Overcome language barriers with clear, written agreements and potentially third-party translation services.

- Quality Control and Inspections: Implement robust quality control measures, including pre-shipment inspections by independent agencies, to ensure product consistency.

- Build Relationships: Long-term partnerships are built on trust. Regular visits and open communication foster stronger supplier relationships.

- Leverage Economies of Scale: Chinese manufacturers often offer excellent value due to large-scale production, especially for high-volume items like зварювальний дріт.

Future-Proofing Your Supply Chain

To future-proof your business, consider strategies that embrace diversification, technological adoption, and sustainability. This means not only exploring new sources for your welding rod and зварювальний дріт but also investing in tools and consumables that are compatible with upcoming automation trends. Strategic partnerships with innovative manufacturers, particularly those emerging from dynamic markets like China, will be key to maintaining agility and competitiveness in a rapidly evolving global industrial landscape.

Conclusion: The Canton Fair as a Catalyst for Progress

The Canton Fair serves as an indispensable barometer for the global industrial tools market, shaping trends and facilitating crucial B2B connections. It highlights the ingenuity and manufacturing prowess of companies like HEBEI YUJINHONG TECHNOLOGY CO.,LTD., who are at the forefront of delivering high-quality welding rod, зварювальний дріт, and other essential industrial hardware. For decision-makers looking to optimize their supply chains, integrate advanced technologies, and secure reliable sources for critical consumables such as the e6011 electrode, the insights gained and partnerships forged at this event are invaluable.

To explore premium e6011 electrode and a comprehensive range of high-performance welding solutions that meet international standards and drive industrial efficiency, we invite you to learn more about HEBEI YUJINHONG TECHNOLOGY CO.,LTD.'s offerings.

Discover HEBEI YUJINHONG's AWS Welding Electrode 6011HEBEI YUJINHONG TECHNOLOGY CO.,LTD. – Your Partner for Industrial Excellence.

-

What is a medium-frequency pulse? What types of welding are suitable for?НовиниNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?НовиниNov.21,2025

-

Welding Knowledge 6НовиниNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?НовиниNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?НовиниNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016НовиниNov.17,2025