Лют . 16, 2025 16:26

Back to list

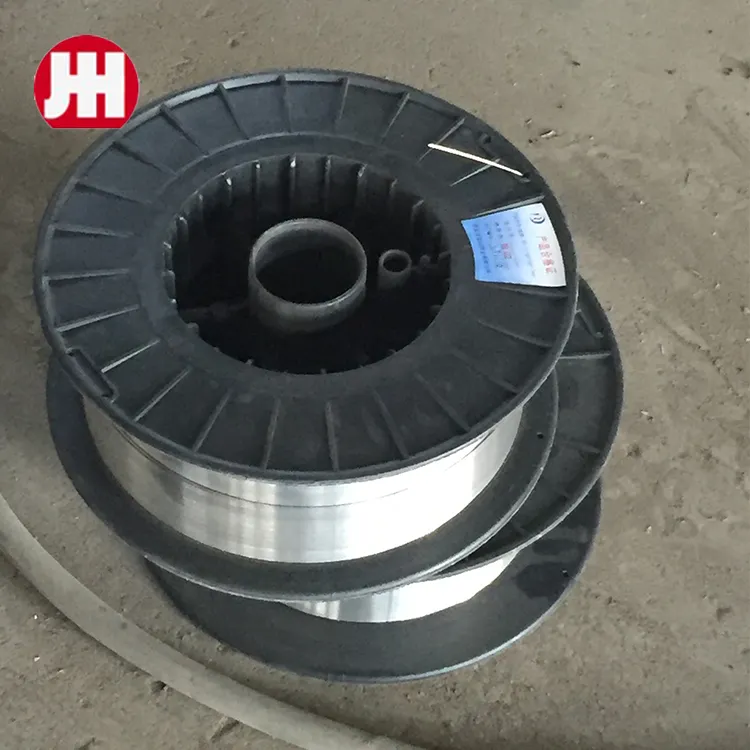

structural welding rod

Navigating the complex world of welding materials is crucial for any professional seeking quality and reliability in their projects. Among the plethora of options available, the wholesale welding rod 6013 stands out for its balance of versatility, durability, and ease of use. But what makes these rods particularly advantageous for industries and individual craftsmen alike?

In terms of trustworthiness, the consistency and reliability of the 6013 rod are backed by its extensive use in a variety of sectors including automotive, structural steel, and repair work. Its compatibility with both AC and DC currents offers additional flexibility, accommodating different welding machine setups without needing specialized equipment. This adaptability ensures that even under varying conditions, the rod performs reliably, cementing its role as a dependable tool in a welder’s arsenal. Expertise in selecting the right welding materials is fundamental to ensuring long-term project success. Professionals who choose the 6013 welding rod for their operations do so with a keen eye on quality diligence. They are assured by the welding rod’s compliance with industry standards and certifications, which validate its performance claims. Such endorsements are vital in maintaining the trust of clients who demand meticulous standards for safety and precision. Experience shared by seasoned welders highlights the 6013 rod's exceptional wetting action, making it easier to maintain a steady weld pool. This characteristic is particularly beneficial for new welders and reduces the skill barrier associated with achieving proficient welds. Training programs across various technical and vocational institutions have integrated the use of the 6013 rod, further cementing its reputation as a foundational learning tool. Ultimately, the wholesale welding rod 6013 is not just a commodity but a pivotal component that supports the ethos of craftsmanship and excellence. For businesses and individuals committed to quality, investing in these rods is a strategic move, one that promises a blend of economical, operational, and practical benefits. Adopting such materials with proven records affirms the commitment to not just meet but exceed industry expectations, driving both innovation and tradition forward in the welding sector.

In terms of trustworthiness, the consistency and reliability of the 6013 rod are backed by its extensive use in a variety of sectors including automotive, structural steel, and repair work. Its compatibility with both AC and DC currents offers additional flexibility, accommodating different welding machine setups without needing specialized equipment. This adaptability ensures that even under varying conditions, the rod performs reliably, cementing its role as a dependable tool in a welder’s arsenal. Expertise in selecting the right welding materials is fundamental to ensuring long-term project success. Professionals who choose the 6013 welding rod for their operations do so with a keen eye on quality diligence. They are assured by the welding rod’s compliance with industry standards and certifications, which validate its performance claims. Such endorsements are vital in maintaining the trust of clients who demand meticulous standards for safety and precision. Experience shared by seasoned welders highlights the 6013 rod's exceptional wetting action, making it easier to maintain a steady weld pool. This characteristic is particularly beneficial for new welders and reduces the skill barrier associated with achieving proficient welds. Training programs across various technical and vocational institutions have integrated the use of the 6013 rod, further cementing its reputation as a foundational learning tool. Ultimately, the wholesale welding rod 6013 is not just a commodity but a pivotal component that supports the ethos of craftsmanship and excellence. For businesses and individuals committed to quality, investing in these rods is a strategic move, one that promises a blend of economical, operational, and practical benefits. Adopting such materials with proven records affirms the commitment to not just meet but exceed industry expectations, driving both innovation and tradition forward in the welding sector.

Previous:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025