6013 welding electrodes factories

The Emergence of 6013 Welding Electrodes Factories

Welding is an essential process in various industries, from construction to manufacturing, where metal components need to be fused together. One of the most popular types of welding electrode used in shielded metal arc welding (SMAW) is the 6013 welding electrode. This article explores the significance of 6013 welding electrodes and the rise of factories dedicated to their production.

Understanding 6013 Welding Electrodes

The 6013 welding electrode is renowned for its versatility and ease of use, making it an ideal choice for both novice and skilled welders. It is particularly suitable for welding mild steel and can be used in various positions. The 60 in its classification signifies a minimum tensile strength of 60,000 psi, while the 1 indicates that it can be used in all welding positions. The 3 denotes the type of coating, which allows for smooth arcs and a stable weld pool, leading to a clean weld appearance.

Moreover, 6013 electrodes are designed to produce less spatter and offer excellent arc stability, making them suitable for a range of applications, including fabrication, repair, and maintenance work. Their ease of use is complemented by a slag that is easy to remove, contributing to the efficiency of the welding process.

The Growth of 6013 Welding Electrodes Factories

As the demand for welding solutions continues to grow, there has been a significant rise in factories specializing in the production of 6013 welding electrodes. Several factors contribute to this trend. Firstly, the expansion of industries that rely on welding processes—such as automotive, construction, and aerospace—has amplified the need for high-quality welding materials. Manufacturers are now prioritizing the production of electrodes that meet industry standards while also being cost-effective.

6013 welding electrodes factories

Secondly, advancements in manufacturing technology have facilitated the efficient production of 6013 electrodes. Modern factories utilize automated processes that enhance consistency and precision in electrode manufacturing. This not only boosts the quality of the electrodes but also allows for scalable production to meet the increasing global demand.

Furthermore, environmental considerations have prompted the shift towards more sustainable manufacturing practices, leading to the development of electrodes with reduced environmental impact. This trend is particularly important as industries worldwide strive to comply with stringent environmental regulations.

Quality Control and Global Standards

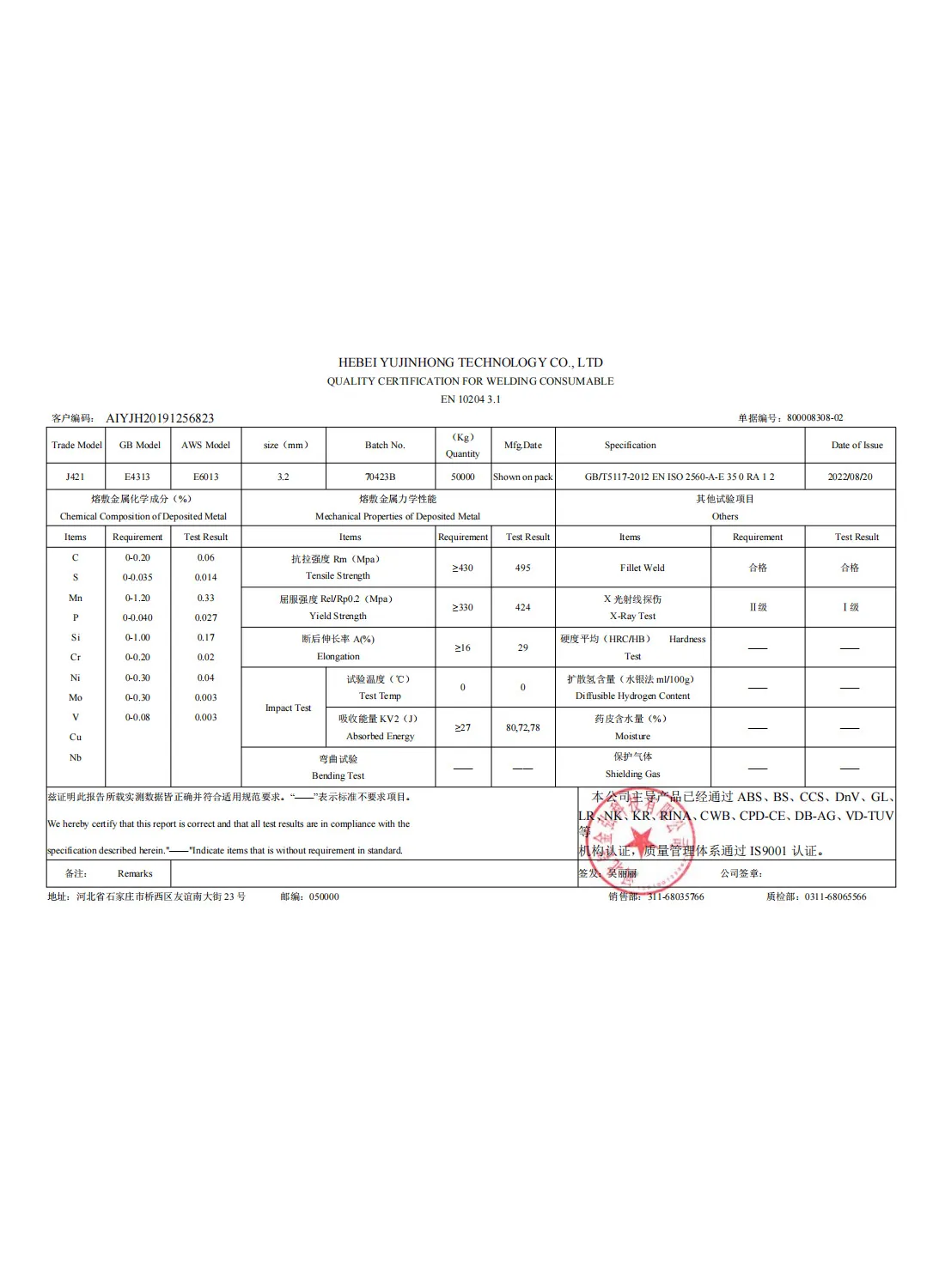

Quality control is crucial in the production of 6013 welding electrodes. Factories are adopting stringent quality assurance measures, including regular testing and certification processes, to ensure that their products not only meet but exceed ISO and AWS standards. This commitment to quality helps manufacturers gain a competitive edge in the market and fosters trust among consumers.

Conclusion

The rise of 6013 welding electrodes factories represents a vital trend in the welding industry. As these factories continue to evolve with technological advancements and a focus on sustainability, they will play a pivotal role in meeting the ever-growing demands of various industries. The 6013 welding electrode, with its practicality and effectiveness, will undoubtedly remain a staple in welding applications for years to come. As manufacturers strive for excellence, the future looks promising for the welding electrode industry.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025