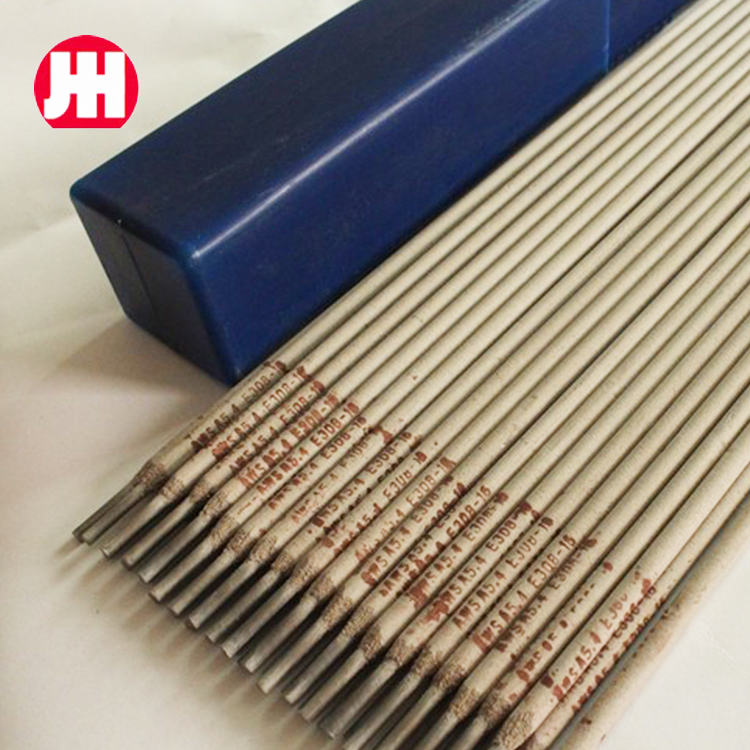

E309 Welding Electrode: Premium Stainless Steel Stick Rods

In the demanding world of industrial fabrication, the choice of welding consumables is paramount to ensuring structural integrity, corrosion resistance, and operational longevity. Among the myriad options, the e309 welding electrode stands out as a critical component, especially when dealing with challenging applications involving dissimilar metal joints and high-temperature environments. This comprehensive guide will explore the intricacies of AWS E309-16 (A302) welding electrodes, covering their technical specifications, manufacturing excellence, diverse applications, and the unparalleled advantages they offer. We will also delve into industry trends, provide essential data, and address common queries, affirming the expertise and trustworthiness behind this indispensable welding solution.

Current Industry Trends in Welding and Stainless Steel Fabrication

The global welding market is witnessing significant growth, driven by increasing industrialization, infrastructure development, and advancements in materials science. Stainless steel, in particular, continues to be a material of choice across various sectors due to its exceptional corrosion resistance, strength, and aesthetic appeal. This surge in demand directly impacts the need for specialized welding electrodes like the e309 welding electrode. Key trends include:

- Increased Demand for Dissimilar Metal Joining: Industries frequently require joining stainless steel to carbon or low-alloy steels, where standard electrodes fail to provide adequate metallurgical compatibility. E309 welding rod is specifically engineered to bridge this gap, preventing issues like carbon migration and brittle intermetallic phases.

- Focus on High-Temperature and Corrosive Environments: Sectors like petrochemicals, power generation, and chemical processing operate under extreme conditions, necessitating welds that can withstand elevated temperatures and aggressive chemical attacks. The robust composition of 309 stainless stick rods ensures reliability in such scenarios.

- Advancements in Welding Automation: While manual arc welding remains prevalent, the push towards automation and robotic welding systems is influencing electrode design, focusing on consistent wire feeding, stable arc characteristics, and reduced spatter for higher productivity.

- Sustainability and Efficiency: Manufacturers are increasingly prioritizing electrodes that offer higher deposition rates, lower energy consumption, and minimal fume generation, aligning with environmental regulations and operational cost reductions.

These trends underscore the enduring relevance and continuous evolution of the e309 welding electrode in modern fabrication.

Unveiling the Technical Prowess: AWS E309-16 (A302) Welding Electrodes for Stainless Steel Parameters

Understanding the technical specifications of an e309 welding electrode is crucial for selecting the right consumable and ensuring optimal weld quality. The AWS E309-16 (A302) classification indicates specific characteristics related to its chemical composition, mechanical properties, and usability. The '16' in E309-16 signifies that it is a titania-calcium type coating, providing excellent arc stability, minimal spatter, and easy slag removal, making it suitable for all-position welding with AC or DCEP (Direct Current Electrode Positive) current. The 'A302' often refers to a specific manufacturer's designation or a variant with particular attributes.

Key Technical Parameters of AWS E309-16 (A302) Welding Electrodes

Below is a detailed table outlining typical product specifications and performance data, illustrating why these e309 welding rod are preferred for demanding applications. Please note that actual values may vary slightly based on specific manufacturer formulations, but generally adhere to AWS A5.4 standards.

| Parameter | Typical Values (AWS E309-16) | Explanation / Significance |

|---|---|---|

| Chemical Composition (Weld Metal, wt%) | Ensures desired metallurgical properties and corrosion resistance. | |

| Carbon (C) | 0.08 max | Lower carbon minimizes carbide precipitation, enhancing intergranular corrosion resistance. |

| Chromium (Cr) | 22.0 - 25.0 | Primary element for corrosion resistance and high-temperature strength. |

| Nickel (Ni) | 12.0 - 14.0 | Stabilizes austenite, improves ductility and toughness. |

| Manganese (Mn) | 0.5 - 2.5 | Deoxidizer, desulfurizer, and improves strength. |

| Silicon (Si) | 0.3 - 0.6 | Deoxidizer, improves fluidity of weld metal. |

| Molybdenum (Mo) | 0.75 max | Enhances pitting corrosion resistance (some variants may have higher Mo). |

| Phosphorus (P) | 0.04 max | Impurity, minimize to prevent hot cracking. |

| Sulfur (S) | 0.03 max | Impurity, minimize to prevent hot cracking and improve ductility. |

| Mechanical Properties (As-Welded) | Indicates the strength and ductility of the weld. | |

| Tensile Strength | ≥ 550 MPa (80 ksi) | Maximum stress the weld metal can withstand before breaking. |

| Yield Strength (0.2% Offset) | ≥ 380 MPa (55 ksi) | Stress at which permanent deformation begins. |

| Elongation in 4D | ≥ 35% | Measure of ductility, how much the material can stretch before breaking. |

| Impact Toughness (Charpy V-notch, @ -20°C) | ≥ 47 J | Resistance to brittle fracture under sudden impact at low temperatures. |

| Typical Welding Parameters | Guidance for optimal welding performance. | |

| Welding Current | AC or DCEP (DC+) | DCEP provides deeper penetration and better arc stability for stainless steel. |

| Amperage Range | Dependent on electrode diameter (e.g., 2.5mm: 50-85A, 3.2mm: 70-110A) | Manufacturer specific, impacts penetration and bead profile. |

| Voltage | 20-30V (typical) | Arc voltage, influenced by arc length and current. |

| Welding Positions | All positions (F, V, OH, H) | Versatile for various joint configurations. |

| Ferrite Content | 8-15% (FN - Ferrite Number) | Controlled ferrite content prevents hot cracking and ensures ductility in the austenitic matrix. |

| Moisture Content of Coating | Low moisture prevents hydrogen-induced cracking and porosity. |

The controlled ferrite content (usually between 8-15 Ferrite Number, FN) in the weld metal is a critical aspect of e309 welding electrode. This balanced microstructure of austenite and a small amount of delta ferrite is essential for preventing hot cracking, especially when welding dissimilar materials or highly restrained joints. Manufacturers meticulously control this balance during production to ensure superior crack resistance and ductility of the weld.

Manufacturing Excellence: The Journey of an E309 Welding Electrode

The quality and performance of e309 welding electrode are directly linked to a precise and meticulously controlled manufacturing process. From raw material selection to final packaging, every step is critical to ensure adherence to stringent international standards like ISO 9001 and AWS A5.4. This dedication to quality ensures the reliability and consistency of every e309 welding rod.

Process Flow for E309 Welding Electrode Manufacturing:

While specific proprietary details vary between manufacturers, the general manufacturing process involves several key stages:

- Core Wire Selection and Preparation:

- Material: High-purity stainless steel wire, typically a modified 309L (low carbon) composition, is chosen as the core. This ensures the foundational metallurgical properties are sound.

- Process: The wire undergoes drawing to achieve precise diameters, followed by cleaning (e.g., acid pickling, degreasing) to remove surface contaminants that could compromise weld quality.

- Flux Material Preparation:

- Material: This is a complex mixture of various mineral powders (e.g., rutile, calcium carbonate, silicates, ferroalloys), binders (e.g., sodium silicate, potassium silicate), and alloying elements (e.g., chromium, nickel, manganese) that contribute to the final weld metal chemistry and arc characteristics. The '16' in E309-16 denotes a titania-calcium coating for excellent arc stability.

- Process: Each component is precisely weighed and thoroughly mixed in high-speed blenders to ensure homogeneity. Particle size distribution is critical for consistent extrusion and coating integrity.

- Flux Extrusion and Coating:

- Process: The prepared flux mixture is fed into an extrusion press. The core wire is centered, and the flux is hydraulically pressed around the wire, forming a uniform, concentric coating. This requires high precision to maintain consistent coating thickness and eccentricity, which directly impacts arc stability and weld puddle control.

- Technology: Modern facilities often use automated extrusion lines to ensure high throughput and consistency.

- Baking (Drying and Curing):

- Process: Immediately after extrusion, the coated electrodes are transferred to carefully controlled baking ovens. This multi-stage process typically involves drying at lower temperatures to remove moisture, followed by curing at higher temperatures (e.g., 350-450°C for basic coatings, lower for rutile) to solidify the binder and remove residual moisture and volatile compounds.

- Significance: Proper baking is crucial. It ensures low hydrogen content in the electrode, preventing hydrogen-induced cracking in the weld metal.

- Finishing and Inspection:

- Process: After baking, electrodes are often tip-cleaned (to ensure good electrical contact) and marked with their classification.

- Testing Standards: Rigorous quality control checks are performed at various stages. This includes:

- Dimensional Checks: Diameter, length, coating concentricity.

- Chemical Analysis: Spectrographic analysis of core wire and flux, and then of actual weld metal deposits to ensure compliance with AWS A5.4.

- Mechanical Testing: Tensile strength, yield strength, elongation, and impact toughness tests on weld metal samples.

- Radiographic Inspection: To check for internal defects like porosity, slag inclusions, or cracks in sample welds.

- Usability Tests: Actual welding trials to assess arc stability, spatter levels, slag detachability, and bead appearance.

- Packaging:

- Process: Electrodes are packaged in hermetically sealed, moisture-proof container111s (e.g., vacuum-sealed foil bags, plastic tubes, or cardboard boxes with desiccant) to protect them from moisture reabsorption, which can severely degrade performance.

- Traceability: Each batch is typically assigned a unique lot number for complete traceability from raw materials to the final product.

This stringent manufacturing and testing regime ensures that each 309 stainless stick rods meets the highest standards for performance, reliability, and safety. Our products, including AWS E309-16 (A302) Welding Electrodes for Stainless Steel, are produced under strict adherence to ISO 9001 quality management systems and are designed for exceptional service life in demanding industrial environments.

Diverse Application Scenarios and Unmatched Advantages

The unique metallurgical characteristics of the e309 welding electrode make it an indispensable choice across a wide spectrum of industries. Its primary strength lies in its ability to weld dissimilar metals and provide excellent resistance to corrosion and high temperatures. Understanding these applications and advantages is key to maximizing its utility.

Primary Application Scenarios:

- Petrochemical and Chemical Processing: Widely used for joining stainless steels (e.g., 304, 321, 347) to carbon or low-alloy steels in pipes, tanks, and heat exchangers. Its corrosion resistance is critical for handling aggressive chemicals.

- Power Generation: Essential for boiler components, steam lines, and exhaust systems, particularly where stainless steels are joined to ferritic steels, and high-temperature strength and oxidation resistance are required.

- Food and Beverage Industry: For fabricating equipment where hygiene and corrosion resistance are paramount, such as mixing tanks, pipelines, and processing machinery. While 308L or 316L are common, 309 may be used for specific structural elements or transitions.

- Automotive Manufacturing: Used in exhaust systems and catalytic converters, especially for joining stainless steel components to mild steel, where thermal cycling and corrosion are concerns.

- Shipbuilding and Marine Applications: For parts exposed to corrosive saltwater environments or where stainless steel structures are integrated with carbon steel hulls.

- Metallurgy and Heavy Industry: For repair welding of stainless steel components in steel mills, foundries, and other heavy manufacturing facilities.

- Water Supply and Drainage Systems: For critical components in water treatment plants and distribution networks where long-term corrosion resistance is vital, often involving the joining of different material grades.

Key Technical Advantages of E309 Welding Electrodes:

- Superior Dissimilar Metal Joining: This is the most significant advantage. The higher alloy content (especially chromium and nickel) of the weld metal acts as a buffer, diluting with the base metals to produce a ductile, crack-resistant joint even when welding austenitic stainless steels to carbon or low-alloy steels. This prevents brittle martensite formation and carbon migration issues.

- Excellent Corrosion Resistance: The high chromium and nickel content provides strong resistance to general corrosion, pitting, and crevice corrosion, making it suitable for aggressive environments.

- High-Temperature Stability and Oxidation Resistance: The weld metal maintains its mechanical properties and resists oxidation at elevated temperatures, crucial for applications in furnaces, exhaust systems, and high-temperature processing equipment.

- Good Weldability and Arc Stability: The titania-calcium coating (E309-16) ensures a smooth, stable arc, low spatter levels, and easy slag removal, enhancing productivity and reducing post-weld cleaning.

- Crack Resistance: The controlled ferrite content in the weld deposit minimizes the risk of hot cracking, a common issue in fully austenitic welds. This is especially important in highly restrained joints.

- Versatility: Suitable for both AC and DCEP current, allowing flexibility in welding equipment usage. It can be used in all welding positions (flat, horizontal, vertical, overhead).

Our AWS E309-16 (A302) Welding Electrodes exemplify these advantages, providing energy-saving and anti-corrosion solutions for diverse industrial challenges, ensuring robust and reliable performance.

Choosing the Right Partner: Manufacturer Comparison and Quality Assurance

Selecting a reliable manufacturer for e309 welding electrode is as crucial as understanding the product itself. The quality, consistency, and support provided by the manufacturer directly impact the success of welding projects. While a direct comparison of specific manufacturers isn't feasible here, we can outline the critical criteria you should consider when evaluating potential suppliers, ensuring you receive a premium 309 stainless stick rods product.

Key Factors for Manufacturer Comparison:

- Certifications and Standards Compliance:

- Look for manufacturers certified to international quality management standards like ISO 9001. This indicates a robust quality control system across all operations.

- Ensure their products meet relevant American Welding Society (AWS A5.4), European (EN ISO 3581-A), or other national standards. Compliance means the product performs as specified.

- Expertise and R&D Capabilities:

- A reputable manufacturer invests in R&D to innovate and improve their electrode formulations, ensuring optimal performance for evolving industry needs.

- Their technical team should possess deep knowledge of metallurgy, welding processes, and application challenges, providing expert guidance and support.

- Product Consistency and Traceability:

- Consistency from batch to batch is paramount. Inconsistent electrodes can lead to unpredictable weld quality and increased rework.

- Manufacturers should provide complete traceability for their products, linking each batch to raw material origins and production parameters. This is crucial for quality audits and problem-solving.

- Quality Control and Testing Procedures:

- Beyond standard certifications, inquire about their internal testing protocols (e.g., destructive and non-destructive testing of weld samples, chemical analysis, mechanical property verification).

- A commitment to rigorous testing, including weldability tests for every batch, signifies a high standard of quality assurance.

- Technical Support and After-Sales Service:

- A strong manufacturer offers comprehensive technical support, including advice on welding parameters, troubleshooting, and material selection.

- Responsive after-sales service and a clear warranty policy demonstrate confidence in their product and commitment to customer satisfaction.

- Industry Reputation and Experience:

- Consider manufacturers with a long-standing history and positive reputation in the welding consumable industry. Years of service often correlate with accumulated expertise and reliable product lines.

- Look for client testimonials, case studies, and industry partnerships that validate their standing.

Our commitment at Steel Tools China is to meet and exceed these criteria. We adhere to stringent quality control, possess extensive industry experience, and maintain certifications that underpin the superior performance of our AWS E309-16 (A302) Welding Electrodes for Stainless Steel.

Tailored Solutions: Customization and Special Requirements

While standard e309 welding electrode products cater to a broad range of applications, specific industrial projects may demand unique welding solutions. Reputable manufacturers recognize this need and offer customization options to meet specialized requirements, further enhancing the utility of e309 welding rod.

- Custom Flux Formulations: For highly specific metallurgical compatibility or enhanced performance characteristics (e.g., improved low-temperature toughness, specific ferrite content ranges, or specialized slag properties), manufacturers can sometimes adjust flux compositions.

- Non-Standard Diameters or Lengths: While typically adhering to standard sizes, certain automated welding processes or confined spaces might require non-standard electrode dimensions.

- Special Packaging: Beyond standard hermetically sealed container111s, custom packaging for extreme storage conditions, specific job site delivery requirements, or enhanced moisture protection (e.g., individual vacuum packs for critical applications) can be provided.

- Specific Testing and Certification: For projects with unusually strict quality assurance protocols, manufacturers can perform additional, non-standard tests or provide specific certifications beyond the typical AWS/ISO compliance.

- Consulting and Technical Support: A strong manufacturer offers in-depth technical consulting to help clients define their needs and design a customized 309 stainless stick rods solution that optimally addresses their unique challenges.

Our team is equipped to discuss and develop customized solutions for your most demanding welding projects, ensuring that the AWS E309-16 (A302) electrodes perfectly align with your operational requirements.

Real-World Impact: Application Cases and Customer Testimonials

The true value of e309 welding electrode is best demonstrated through its successful application in real-world scenarios. These case studies highlight the problem-solving capabilities and robust performance of these electrodes, reinforcing their practical experience and reliability.

Case Study 1: Heat Exchanger Repair in a Petrochemical Plant

Challenge: A critical heat exchanger in a petrochemical plant, constructed from 304L stainless steel, required repair welding to patch a section that needed to be joined to a newly fabricated carbon steel support structure. The joint was highly restrained, and preventing cracking and ensuring corrosion resistance was paramount for operational safety and longevity.

Solution: AWS E309-16 (A302) Welding Electrodes were selected due to their proven ability to provide a strong, ductile, and crack-resistant weld when joining dissimilar metals (304L SS to Carbon Steel). The low spatter and easy slag removal minimized post-weld cleaning, accelerating the repair process.

Outcome: The repair was successfully completed, resulting in a robust joint that exhibited excellent integrity under operational temperatures and corrosive conditions. The plant experienced minimal downtime, attributing the swift and reliable repair to the superior performance of the e309 welding electrode.

Customer Feedback: "The E309 electrodes delivered exceptional arc stability and produced a clean, strong weld. We had concerns about cracking given the stress in the joint, but the weld held up perfectly. A reliable product that saved us significant downtime." - Plant Manager, Major Petrochemical Co.

Case Study 2: Fabricating a High-Temperature Exhaust System for a Marine Engine

Challenge: A marine engine manufacturer needed to fabricate complex exhaust manifold sections that involved joining various grades of stainless steel to mild steel components. These systems are exposed to extreme temperatures, vibration, and corrosive exhaust gases, demanding welds with high integrity and thermal fatigue resistance.

Solution: Using 309 stainless stick rods, fabricators were able to create robust joints between components. The higher alloy content of the E309 weld metal provided the necessary buffer zone, accommodating the differing thermal expansion rates of the base metals and preventing stress-induced cracking.

Outcome: The resulting exhaust systems passed rigorous marine classification society tests, demonstrating excellent resistance to thermal cycling and prolonged exposure to corrosive environments. The consistent quality of the e309 welding rod contributed to higher fabrication efficiency and reduced rejection rates.

Customer Feedback: "For our high-performance marine exhaust systems, reliability is everything. These e309 welding electrodes consistently deliver strong, ductile welds that withstand the harsh marine environment. They are our go-to for critical dissimilar metal joints." - Lead Fabricator, Marine Engineering Firm.

Frequently Asked Questions (FAQ) about E309 Welding Electrodes

Here are answers to some common professional questions regarding e309 welding electrode, providing further clarity and expertise:

- What is the primary application of e309 welding electrode?

Its primary application is welding dissimilar metals, specifically joining austenitic stainless steels (like 304, 321, 347) to carbon or low-alloy steels. It's also used for welding AISI 309 stainless steel to itself, for stainless steel cladding on carbon steel, and as a buffer layer for hardfacing applications. - Why is the ferrite content important in 309 stainless stick rods weld metal?

The controlled ferrite content (typically 8-15 Ferrite Number, FN) in the as-welded microstructure is crucial for preventing hot cracking. Fully austenitic stainless steel welds are highly susceptible to hot cracking, and a small amount of delta ferrite acts as a sponge to absorb impurities, thereby minimizing this risk and improving ductility. - Can e309 welding rod be used with AC current?

Yes, AWS E309-16 electrodes are designed to operate effectively with both AC (Alternating Current) and DCEP (Direct Current Electrode Positive) polarity. DCEP is generally preferred for deeper penetration and a more stable arc on stainless steel. - What are the typical storage requirements for e309 welding electrode?

To prevent moisture pickup, which can lead to hydrogen porosity and cracking, electrodes should be stored in dry conditions, ideally in hermetically sealed container111s. Opened packages should be stored in a heated cabinet (e.g., 100-150°C) or re-baked according to manufacturer specifications if exposed to atmosphere for extended periods. - What does the "16" in AWS E309-16 signify?

The "16" denotes the type of flux coating. It signifies a rutile-basic (titania-calcium) coating, which provides good arc stability, minimal spatter, excellent bead appearance, and easy slag removal. This type of coating is generally suitable for all welding positions. - How does e309 welding electrode differ from E308L or E316L?

E308L is designed for welding 304L stainless steel (low carbon). E316L is for 316L stainless steel (with molybdenum for enhanced pitting corrosion resistance). E309 welding electrode has significantly higher chromium and nickel content than both E308L and E316L, specifically designed to handle the dilution that occurs when welding stainless steel to carbon or low-alloy steels, thereby maintaining a suitable alloy content in the weld metal to prevent issues like martensite formation. - What are the safety precautions when welding with 309 stainless stick rods?

Standard welding safety precautions apply: use appropriate personal protective equipment (welding helmet with proper shade, gloves, flame-retardant clothing), ensure adequate ventilation to remove fumes, and be aware of electrical hazards. Specifically for stainless steel, ensure proper ventilation to manage chromium and nickel fumes.

Commitment to Excellence: Delivery, Warranty, and Support

Our commitment extends beyond providing high-quality e309 welding electrode. We prioritize seamless logistics, transparent warranty policies, and dedicated customer support to ensure your complete satisfaction and foster long-term partnerships. We understand that timely delivery and reliable after-sales service are crucial components of your operational success.

- Efficient Delivery Cycle: We maintain robust inventory management and efficient logistics networks to ensure prompt processing and delivery of your orders, minimizing project delays. Typical delivery times are communicated clearly at the time of order confirmation.

- Comprehensive Quality Warranty: Our AWS E309-16 (A302) Welding Electrodes for Stainless Steel are backed by a comprehensive quality warranty, guaranteeing their compliance with all stated specifications and performance standards. Any manufacturing defects are addressed promptly and professionally.

- Dedicated Customer Support: Our team of experienced technical professionals is available to provide expert guidance, answer your queries, and offer troubleshooting assistance before, during, and after your purchase. From product selection to application best practices, we are here to support your welding success.

Trust in our e309 welding electrode and our unwavering commitment to your project's success.

Conclusion

The e309 welding electrode, particularly the AWS E309-16 (A302) classification, stands as a cornerstone in challenging welding applications, especially where dissimilar metals meet or high-temperature and corrosive environments prevail. Its meticulously controlled chemical composition, balanced ferrite content, and advanced flux coating ensure superior performance, mitigating common welding issues like hot cracking and providing robust, corrosion-resistant joints. From petrochemical plants to marine engine fabrication, the real-world application cases underscore its unparalleled reliability and the tangible benefits it brings to industrial operations.

Choosing a manufacturer with a strong commitment to ISO standards, rigorous quality control, and comprehensive technical support further enhances the value proposition of these essential 309 stainless stick rods. By understanding its technical prowess, manufacturing excellence, and diverse applications, engineers and fabricators can confidently leverage the e309 welding electrode to achieve optimal weld integrity and long-term performance in their most critical projects.

References and Further Reading:

- AWS A5.4/A5.4M:2012, Specification for Stainless Steel Electrodes for Shielded Metal Arc Welding. (Industry Standard)

- "Welding Metallurgy and Weldability of Stainless Steels" by J.C. Lippold and D.J. Kotecki. (Academic Text)

- Miller Electric Mfg. LLC. (2016). "Dissimilar Metal Welding." Miller Welding Blog. Retrieved from [https://www.millerwelds.com/resources/article-library/dissimilar-metal-welding](https://www.millerwelds.com/resources/article-library/dissimilar-metal-welding) (Industry Forum/Resource)

- The Fabricator. (2020). "Understanding stainless steel stick electrodes." The Fabricator Magazine. Retrieved from [https://www.thefabricator.com/article/arcwelding/understanding-stainless-steel-stick-electrodes](https://www.thefabricator.com/article/arcwelding/understanding-stainless-steel-stick-electrodes) (Industry Publication)

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025