china welding rod 3.2mm factories

Exploring the Landscape of 3.2mm Welding Rod Factories in China

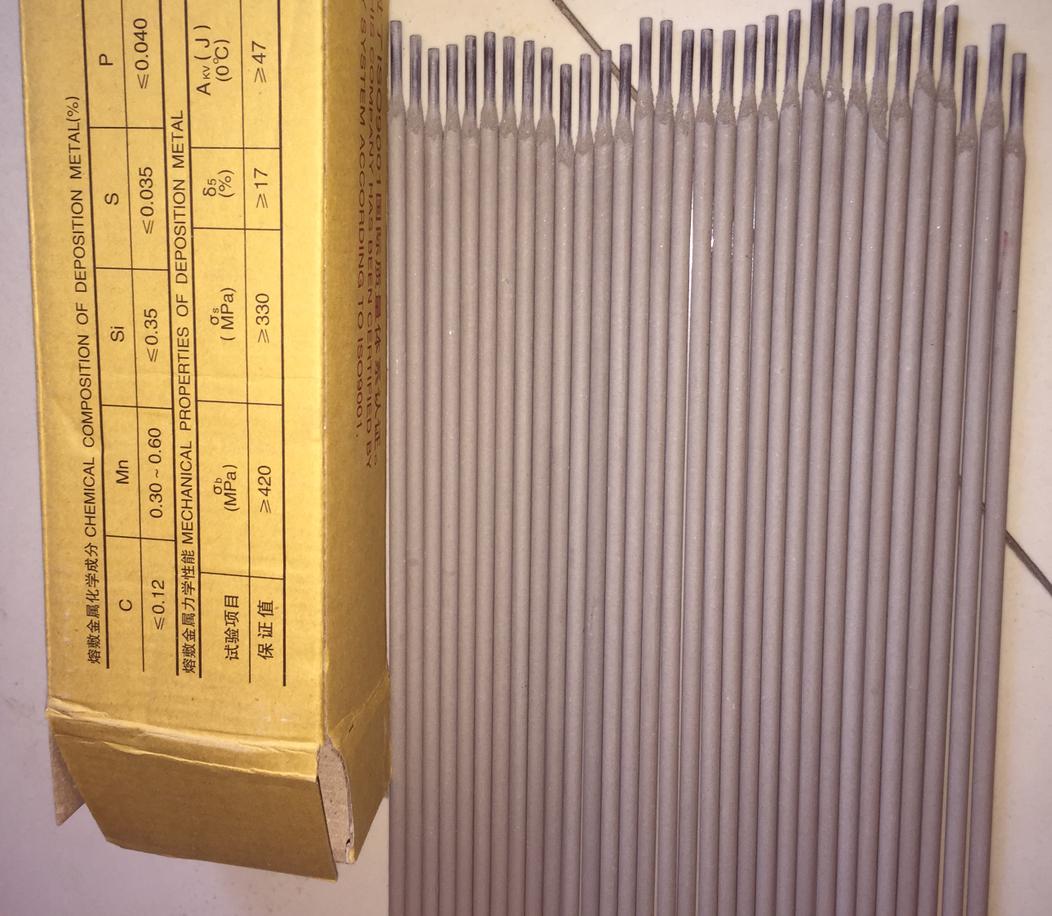

Welding is an essential process in various industries, including construction, manufacturing, and repair services. In this context, welding rods play a critical role as they provide the necessary material for joining metals. Among the various specifications, 3.2mm welding rods are particularly popular due to their versatility and effectiveness across different applications. As the global demand for welding rods continues to grow, China has emerged as a prominent player in manufacturing, establishing a vast network of factories dedicated to producing high-quality 3.2mm welding rods.

The Significance of 3.2mm Welding Rods

The 3.2mm welding rods are favored for several reasons. They are ideal for both amateur and professional welders due to their manageable size and compatibility with various welding machines. The rods can be used in a wide range of applications, including metal fabrication, automotive repairs, and construction work. Additionally, 3.2mm rods are applicable for both DC and AC welding processes, making them a versatile choice for many industries.

The Chinese Manufacturing Advantage

China's rise as a manufacturing powerhouse can be attributed to several factors that significantly enhance its production capabilities. Firstly, the country boasts a robust supply chain for raw materials, which is essential for producing welding rods. Key ingredients—such as metals and alloys—are readily available within the country, ensuring that manufacturers can maintain quality and reduce production timelines.

Moreover, China has invested extensively in technology and infrastructure, allowing for efficient production processes. Factories are equipped with advanced machinery that can optimize welding rod production, from sintering to coating. This technological edge not only boosts productivity but also enhances the quality of the end products, enabling Chinese manufacturers to compete on a global scale.

The Role of Quality Control

Quality control is paramount in the production of welding rods, as these materials are crucial for the integrity and safety of welded structures. Chinese factories are increasingly implementing stringent quality control measures to ensure that their products meet both local and international standards. These measures include metallurgical testing, tensile strength analysis, and compliance with international certifications such as ISO 9001.

china welding rod 3.2mm factories

Manufacturers are also adopting eco-friendly practices by utilizing sustainable materials and reducing emissions during the production process. Such commitments not only improve product quality but also enhance the overall environmental footprint of the industry.

Notable Manufacturers in China

There are several key players in the Chinese welding rod manufacturing sector. These companies have established reputations for producing high-quality 3.2mm welding rods. One of the leading manufacturers is Jinan Jinlian Welding Material Co., Ltd., known for its innovative approaches and diverse product range. Another prominent name is TIANJIN ZHONGYI WELDING MATERIALS CO., LTD., which has gained a significant market share by focusing on quality and customer-oriented services.

These manufacturers often participate in international trade fairs and exhibitions, showcasing their products to potential buyers. Through these platforms, they aim to expand their market reach and explore partnerships with distributors and retailers worldwide.

Exporting and Global Reach

As demand for welding rods rises globally, Chinese factories are positioning themselves as key exporters. The ability to scale production while maintaining competitive pricing gives them an edge in international markets. Furthermore, Chinese manufacturers are increasingly exploring partnerships with foreign companies to tap into local markets and enhance their distribution channels.

Countries in North America, Europe, and Asia show significant interest in Chinese-made welding rods, primarily due to their quality and affordability. As trade relationships strengthen, the global footprint of Chinese manufacturers continues to grow, making them indispensable suppliers in the welding industry.

Conclusion

The manufacturing landscape for 3.2mm welding rods in China is dynamic and robust, marked by advanced technology, stringent quality control, and a commitment to sustainability. With a well-established network of factories, China has positioned itself as a global leader in welding rod production, catering to an ever-growing demand from various industries worldwide. As innovations and improvements in manufacturing processes continue, the future of welding rods—and the factories that produce them—looks promising, ensuring that this critical industry will thrive for years to come.

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025