E309 Welding Electrode – Dissimilar Metals, Smooth Arc

E309 Welding Electrode is a key solution in the manufacturing industry, specifically within Fabricated metal products and Welding material manufacturing. This article explores how HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- E309 Welding Electrode Overview

- Benefits & Use Cases of E309 Welding Electrode in Welding material manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on E309 Welding Electrode from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

E309 Welding Electrode Overview

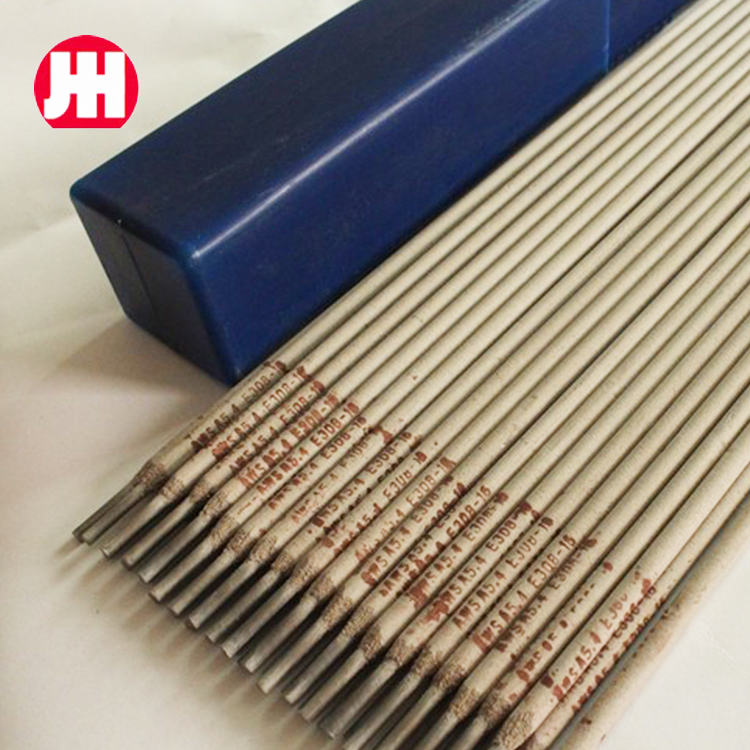

The E309 Welding Electrode, often referred to as an e309 welding rod or 309 stainless stick rods in the field, is an austenitic stainless steel SMAW electrode designed primarily for joining dissimilar metals—most commonly stainless steels to carbon or low-alloy steels—and for buffer layers or clad overlays. Classified typically as AWS A5.4 E309-16, it features a rutile coating for smooth arc starts, stable arc performance, and easy slag removal on AC or DCEP. Its chemistry typically targets around 23% Cr and 12–13% Ni, delivering excellent crack resistance and corrosion performance in service.

In demanding production environments across fabricated metal products, the E309 Welding Electrode is valued for its versatility and reliability. Common diameters (2.5/3.2/4.0 mm) cover thin sheet to heavy plate, while all-position capability (notably in the “-16” coating) supports flexible shop scheduling. Typical mechanical properties include high tensile strength and good ductility, making it suitable for structural and process equipment applications. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. manufactures and supplies E309 electrodes to global specs, with consistent coating concentricity, low spatter, and batch-to-batch stability—key factors for B2B buyers managing throughput, rework, and quality KPIs.

Benefits & Use Cases of E309 Welding Electrode in Welding material manufacturing

In welding material manufacturing and downstream fabrication shops, the E309 Welding Electrode is a workhorse for joining 304/316 stainless components to carbon steel frames, attaching stainless liners to mild-steel shells, and applying corrosion-resistant overlays in food equipment, chemical processing, energy, and HVAC assemblies. It minimizes dilution concerns and hot cracking when bridging different base metals, and its stable slag system enables clean beads and simplified post-weld finishing. For maintenance teams, E309 offers practical stock reduction: one rod covers a broad range of dissimilar joint repairs and rebuilds.

- Applications: dissimilar joints (SS to CS), transition/buffer layers before E308/E316 overlays, and corrosion-resistant cladding.

- Advantages: AC/DCEP usability, smooth arc, low spatter, easy slag release, and solid ferrite balance for crack resistance.

- Process consistency: supports all-position welding, improving scheduling flexibility and reducing operator learning curve.

Backed by HEBEI YUJINHONG TECHNOLOGY CO.,LTD.’s sector expertise, buyers gain dependable technical support—covering rod selection, joint design, and procedure tuning (e.g., interpass control ~150 °C, moderate preheat on the carbon steel side when needed, and short arc technique). This partnership approach helps production managers hit first-pass yield and delivery targets while safeguarding corrosion and mechanical performance in service.

Cost, Maintenance & User Experience

Total cost of ownership with E309 Welding Electrode hinges on consumable stability, deposition efficiency, and rework avoidance. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. focuses on consistent coating quality to reduce spatter and slag inclusions, saving grinding time and consumable wear. In many shops, this translates to shorter cycle times and improved deposition per labor hour—key ROI drivers for B2B decision makers balancing capacity and cost per weld. Proper storage (dry conditions; re-bake around 150–200 °C for 1–2 hours if moisture pickup occurs) further protects bead appearance and porosity control.

- Durability: reliable arc stability across heats and diameters reduces operator adjustments and downtime.

- ROI: less rework and faster cleanup can lower total joint cost in dissimilar welding versus multi-step processes.

- User feedback: fabrication teams note clean slag peel and predictable wetting, aiding weld appearance and inspection acceptance.

From a maintenance viewpoint, the e309 welding rod is a practical inventory item: it handles a wide range of unplanned repairs where base-metal identification is uncertain. Its versatility keeps equipment uptime high, which is vital for shops with tight delivery windows.

Sustainability & Market Trends in manufacturing

Sustainability and compliance are shaping procurement in welding consumables. Buyers increasingly seek products aligned with international standards (such as AWS A5.4 for stainless electrodes) and responsible manufacturing practices. The E309 Welding Electrode supports equipment life extension—through dissimilar joints and protective overlays—reducing scrap and enabling longer service intervals, which contributes to resource efficiency. As more fabricated products serve hygienic, energy, and process industries, corrosion-resistant joining with 309 stainless stick rods helps reduce premature failures and the environmental costs of early replacements.

- Regulatory focus: safe handling, proper fume control, and clear documentation are becoming standard expectations.

- Market growth: demand for dissimilar welding and cladding rises with multiphase equipment, modular skids, and lifecycle-driven maintenance.

- Supplier positioning: HEBEI YUJINHONG TECHNOLOGY CO.,LTD. emphasizes consistent quality, traceability, and customer guidance to help clients meet production and sustainability goals.

Conclusion on E309 Welding Electrode from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

For manufacturers in fabricated metal products and welding material manufacturing, the E309 Welding Electrode delivers dependable performance for dissimilar joints, overlay work, and maintenance. Its arc stability, versatility, and corrosion resistance help drive quality, throughput, and cost control. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. stands out as a reliable partner, providing consistent consumables and responsive technical support from selection to procedure optimization. Ready to strengthen your welding program? Contact us: email: info@steeltoolschina.com — Visit our website: https://www.steeltoolschina.com

-

What is a medium-frequency pulse? What types of welding are suitable for?YangiliklarNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?YangiliklarNov.21,2025

-

Welding Knowledge 6YangiliklarNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?YangiliklarNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?YangiliklarNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016YangiliklarNov.17,2025