Flux Cored Welding Wire: The Go-To Solution for Heavy-Duty Fabrication

If you're working with thick steel, outdoor structures, or projects that demand high deposition rates, then flux cored welding wire is a smart choice. This wire combines the high productivity of continuous welding with the metallurgical benefits of flux, allowing for strong, clean welds even in less-than-perfect environments.

Whether you’re sourcing flux cored welding wire for sale, comparing brands, or reviewing top flux cored welding wire suppliers, understanding the differences in wire types, applications, and specs will help you make the right decision for your operation.

What Is Flux Cored Welding Wire?

Flux cored welding wire (FCAW wire) is a tubular wire filled with flux compounds that perform various functions during welding—such as shielding the weld pool, enhancing arc stability, and improving mechanical properties.

Unlike solid MIG wire, flux cored wire does not rely solely on shielding gas (though it can use one). It’s ideal for:

Outdoor welding where wind may disrupt shielding gas

Thick material welding where deeper penetration is needed

High-speed production and automated welding lines

There are two main types:

Self-Shielded Flux Cored Wire (FCAW-S)

No external shielding gas required

Great for fieldwork, repair, and structural steel

More portable, but produces more spatter and smoke

Gas-Shielded Flux Cored Wire (FCAW-G)

Requires CO₂ or mixed gas (typically 75% Ar / 25% CO₂)

Cleaner welds, less spatter

Used in shop and robotic welding

Flux Cored Welding Wire Advantages

Compared to solid wire or stick electrodes, flux cored wire offers:

Higher deposition rates

All-position capability (for some classifications)

Better penetration on thick steel

Fewer starts and stops (continuous wire feed)

Improved productivity for long welds and structural work

Common Specifications of Flux Cored Welding Wire

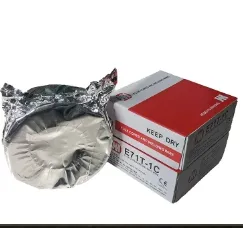

If you're browsing flux cored welding wire for sale, you'll often see the AWS classification. Here are a few common specs:

|

AWS Classification |

Tavsif |

Use Case |

|

E71T-1 |

Gas-shielded, all-position, low spatter |

Structural steel, fabrication shops |

|

E71T-8 |

Self-shielded, vertical down |

Bridge construction, field welding |

|

E70T-1 |

Mild steel, CO₂ shielding, high deposition |

Shipbuilding, heavy equipment |

|

E91T1-K2 |

Low-temp, low-alloy, high toughness |

Offshore, cold climates |

Available diameters typically include 0.9 mm (0.035"), 1.2 mm (0.045"), and 1.6 mm (1/16").

Where to Buy: Flux Cored Welding Wire for Sale

Whether you’re buying a few spools or stocking up for a large project, you’ll find flux cored welding wire for sale through:

Local welding supply stores

Online distributors

Authorized dealers of major brand

Direct from manufacturers (especially for bulk drum packaging)

When shopping, consider:

Packaging (spools, coils, bulk drums)

Wire cleanliness (surface finish affects feeding)

Shelf life (store in dry conditions to avoid moisture in flux)

Pricing by volume (per spool vs. per kg discounts

Choosing the Right Flux Cored Welding Wire Supplier

Not all flux cored welding wire suppliers are created equal. A reliable supplier should offer:

Certified quality (AWS/ISO/DNV approved products)

Application support (help with WPS, procedure testing, or demos)

Custom wire formulations (for special alloys or projects)

Fast delivery and local stocking where possible

Private label or OEM services (if you’re a distributor)

Top global suppliers include:

Lincoln Electric

ESAB

Kobelco

Bohler Welding

Hyundai

Select Arc

Kiswel

If you're running a fabrication shop or construction company, choose a supplier who can scale with your volume, respond quickly to demand, and provide consistent performance batch after batch.

Flux Cored Wire vs. Solid MIG Wire

|

Feature |

Flux Cored Wire |

Solid MIG Wire |

|

Penetration |

Deeper |

Moderate |

|

Out-of-position welds |

Better (vertical, overhead) |

Limited unless pulsed spray |

|

Himoya qiluvchi gaz |

Optional (self-shielded types) |

Required |

|

Spatter/smoke |

Higher |

Lower |

|

Travel speed |

Slower |

Faster on thin material |

|

Best for |

Structural steel, outdoor work |

Sheet metal, shop welding |

Typical Pricing (2025 Estimates)

|

Wire Type |

Price (USD/kg) |

|

E71T-1 gas-shielded wire |

$2.50 – $4.00 |

|

E71T-8 self-shielded wire |

$2.80 – $4.50 |

|

Stainless flux cored wire |

$7.00 – $11.00 |

|

Low-alloy flux cored wire |

$4.00 – $7.50 |

Bulk packaging (250 kg drums) offers lower per-kg pricing compared to 15 kg spools.

Flux Cored Welding Wire FAQs

Q1: Can flux cored wire be used without gas?

A: Yes—self-shielded types (FCAW-S) are designed to operate without external shielding gas, making them perfect for fieldwork.

Q2: What’s the difference between E71T-1 and E71T-8?

A: E71T-1 is gas-shielded and produces a cleaner weld; E71T-8 is self-shielded, suitable for outdoor or windy environments, but produces more slag and smoke.

Q3: Does flux cored wire work on thin material?

A: It can, but solid wire or pulsed MIG may be better for very thin sections to avoid burn-through.

Q4: Can I use flux cored wire with my MIG welder?

A: Yes, but your machine must be set up for FCAW, and polarity may need to be reversed (most self-shielded wires use DCEN).

Q5: Where can I find reliable flux cored welding wire suppliers?

A: Look for authorized dealers of major brands or reach out to industrial distributors with technical support and volume pricing.

-

What is a medium-frequency pulse? What types of welding are suitable for?YangiliklarNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?YangiliklarNov.21,2025

-

Welding Knowledge 6YangiliklarNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?YangiliklarNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?YangiliklarNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016YangiliklarNov.17,2025