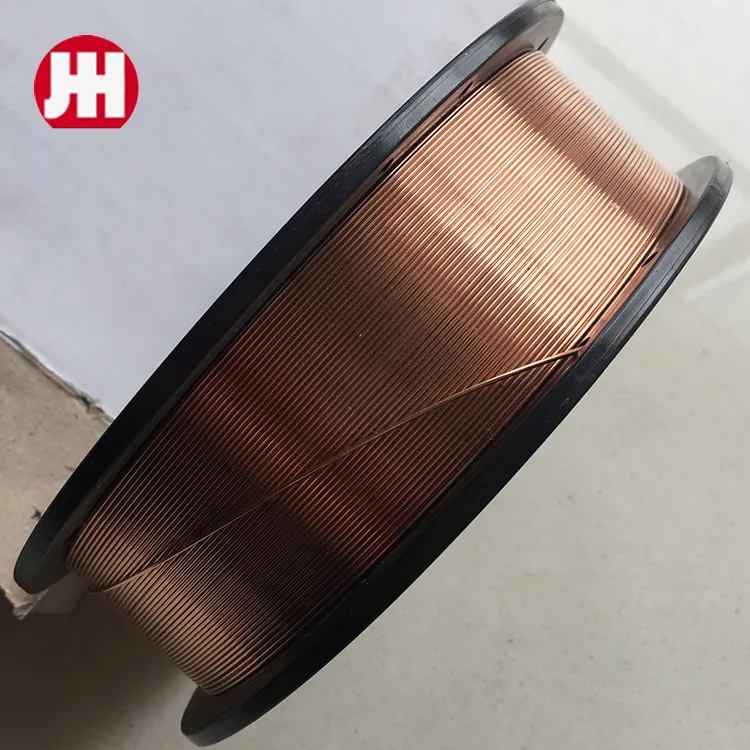

gasless aluminum mig wire supplier

The Rise of Gasless Aluminum MIG Wire Suppliers A New Era in Welding Solutions

In the ever-evolving landscape of welding technology, gasless aluminum MIG (Metal Inert Gas) wire has emerged as a significant innovation, catering to the needs of manufacturers and hobbyists alike. As industries seek more efficient and versatile welding solutions, the demand for gasless aluminum MIG wire suppliers is on the rise. This article explores the advantages of gasless MIG welding, the factors driving its popularity, and what to consider when choosing a reliable supplier.

Understanding Gasless Aluminum MIG Welding

Gasless MIG welding, also known as self-shielded MIG welding, utilizes a tubular wire filled with flux to create a shielding gas during the welding process. Traditional MIG welding typically requires an external gas supply, such as argon or carbon dioxide, to protect the weld pool from contamination. However, gasless MIG welding eliminates this requirement and simplifies the process, making it an attractive option for various applications.

One of the main advantages of gasless aluminum MIG welding is its portability. Without the need for gas cylinders and hoses, welders can easily transport their equipment to different job sites. This feature is particularly beneficial for contractors and DIY enthusiasts who may need to work in diverse environments. Additionally, gasless MIG welding is less affected by wind and drafts, making it suitable for outdoor applications where conventional welding may struggle.

Advantages of Gasless Aluminum MIG Wire

1. Ease of Use Gasless MIG welding is user-friendly, making it accessible for beginners. The straightforward setup allows welders to focus more on technique rather than dealing with gas-related issues.

2. Cost-Effectiveness Over time, the absence of gas costs can lead to significant savings for businesses. This reduction in operational expenses is especially appealing to small companies and independent contractors.

3. Versatility Gasless aluminum MIG wire can be used on various materials, including aluminum and steel. This versatility makes it a valuable addition to any welding operation, allowing for multiple applications without changing equipment.

4. Reduced Cleanup Without the contamination risks associated with gas welding, the cleanup process becomes easier and quicker. The resulting welds are generally cleaner, requiring less post-weld treatment.

Growing Demand for Gasless Aluminum MIG Wire Suppliers

As awareness of the benefits of gasless aluminum MIG welding continues to grow, so does the need for suppliers who can provide high-quality welding wires

. This surge in demand is driven by several factorsgasless aluminum mig wire supplier

- Industrial Growth As sectors such as construction, automotive, and manufacturing expand, the need for efficient welding solutions has increased. Gasless welding offers a practical solution for many industrial applications, contributing to its rising popularity.

- DIY Culture The do-it-yourself movement has led to a significant uptick in hobbyists and enthusiasts taking up welding. The accessibility and ease of use associated with gasless MIG welding appeal to this demographic.

- Sustainability Concerns With a growing emphasis on sustainability, businesses are seeking ways to reduce waste and enhance efficiency. Gasless welding aligns with these goals, offering a more streamlined process with minimal material wastage.

Choosing the Right Supplier

Selecting a reliable gasless aluminum MIG wire supplier is crucial for achieving optimal results in welding projects. Here are some key considerations

1. Quality and Certification Ensure that the supplier offers high-quality products that meet industry standards. Look for certifications that attest to the wire’s performance and safety.

2. Product Range A good supplier should provide a variety of gasless aluminum MIG wires, suitable for different applications and materials. This flexibility ensures you can find the right product for your needs.

3. Customer Support A supplier that offers excellent customer service can help resolve queries and technical issues. Look for suppliers with knowledgeable staff who can provide guidance on product selection and usage.

4. Pricing and Delivery Compare the pricing of different suppliers while considering the quality of their products. Additionally, assess their delivery terms to ensure you receive your materials promptly.

Conclusion

The emergence of gasless aluminum MIG wire has transformed the welding industry, offering a versatile and efficient solution for various applications. The growing demand for gasless welding products has led to the rise of specialized suppliers, providing quality materials to meet the needs of welders globally. By understanding the advantages of gasless MIG welding and carefully selecting a reputable supplier, businesses and individuals can enhance their welding capabilities and achieve superior results.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025