low smoke welding rod 7018 supplier

Understanding Low Smoke Welding Rod 7018 An Overview of Suppliers

When it comes to welding, selecting the right materials is crucial for achieving high-quality results. Among the various welding rods available, the low smoke welding rod 7018 has gained prominence due to its unique characteristics. This article explores the benefits of low smoke 7018 rods, their applications, and the key factors to consider when selecting a supplier.

What is Low Smoke Welding Rod 7018?

The 7018 welding rod is known for its versatile performance, primarily used in arc welding processes. The designation 7018 refers to the rod's mechanical properties and composition. The first two digits represent the minimum tensile strength, while the “01” indicates it’s suitable for all positions. The “8” signifies the type of coating, which in this case, is designed to produce low smoke and spatter when heated.

Low smoke welding rods are particularly advantageous as they produce minimal fumes during the welding process. This is essential for maintaining a safer work environment and ensuring better visibility for the welder. Moreover, the low smoke rods help in reducing the need for additional ventilation, making them suitable for enclosed spaces.

Benefits of Low Smoke Welding Rod 7018

1. Reduced Fumes As the name suggests, low smoke rods generate significantly less smoke compared to traditional rods. This results in a cleaner working area and minimizes health risks associated with prolonged exposure to welding fumes.

2. Superior Weld Quality The 7018 rod is renowned for producing strong, durable welds. It is specifically formulated with low hydrogen content, which helps to prevent cracking in the welded joints.

3. Versatile Applications Low smoke 7018 rods can be used for various applications, including structural steel, pipelines, and fabricating agriculture equipment. Their versatility makes them a popular choice among welders in numerous industries.

4. Ease of Use Welders often prefer 7018 rods due to their forgiving nature, allowing them to create quality welds even under less than ideal conditions. They can be used in all welding positions, making them highly adaptable.

Selecting a Supplier of Low Smoke Welding Rod 7018

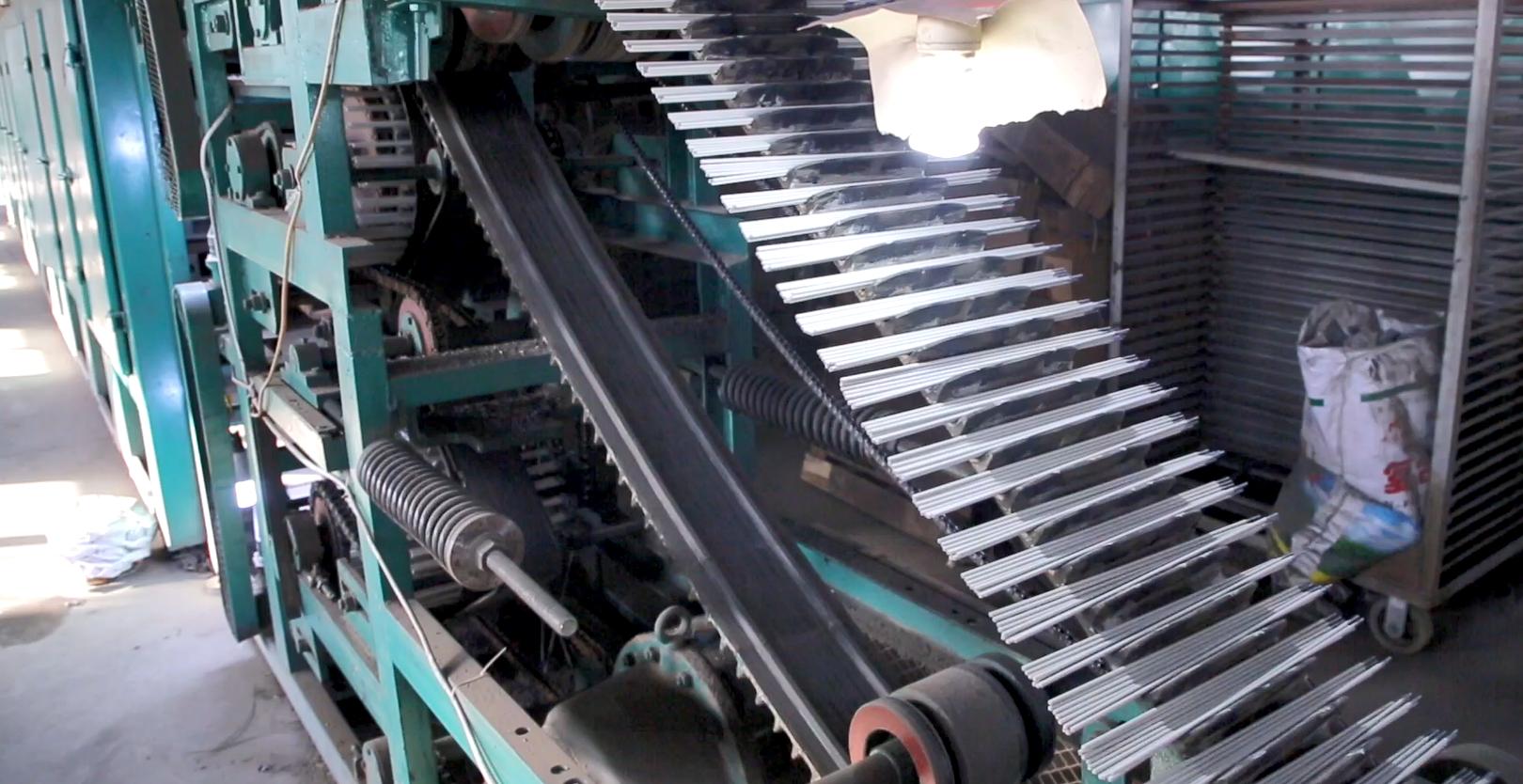

low smoke welding rod 7018 supplier

Choosing the right supplier for low smoke welding rod 7018 is crucial for ensuring the quality and performance of your welding projects. Here are some key factors to consider

1. Quality Assurance It's vital to partner with suppliers who guarantee high-quality products. Look for those with certifications that meet industry standards, such as ISO certifications.

2. Variety of Products A good supplier should offer a range of welding rods, including different sizes and specifications of 7018 rods. This will allow you to choose the rods that best fit your project requirements.

3. Reputation and Experience Suppliers with a strong reputation in the industry are more likely to provide reliable products. Research reviews and testimonials from other customers to gauge their experiences.

4. Technical Support Look for suppliers that offer technical assistance. Whether you need help choosing the right rod or troubleshooting welding issues, having access to knowledgeable support can be incredibly beneficial.

5. Pricing and Availability While price is often a consideration, it should not be the sole determining factor. Evaluate the overall value provided by the supplier, including product quality, support, and delivery times.

6. Sustainability Practices In today’s environmentally conscious market, consider suppliers who implement sustainable practices in their manufacturing processes. This not only contributes to environmental protection but can also enhance your company’s reputation.

Conclusion

Low smoke welding rod 7018 has become a favored choice among welders for its reduced fume production and superior performance. Understanding its benefits and applications is essential for welders and business owners alike. When selecting a supplier, it is crucial to evaluate quality, product range, reputation, support, pricing, and sustainability practices. By doing so, you can ensure that your welding projects are successful, safe, and environmentally friendly.

Whether you are a beginner or a seasoned welder, the right low smoke welding rod can make all the difference in your welding endeavors.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025