Reliable Suppliers for MIG Welding Aluminum Wire Solutions and Equipment

MIG Welding Aluminum Wire Suppliers A Comprehensive Guide

MIG (Metal Inert Gas) welding is a popular technique in the fabrication and repair of aluminum components. This method offers high-speed welding with good penetration and can produce strong, clean welds. However, the quality of the weld greatly depends on the type of aluminum wire used, making it essential to find a reliable MIG welding aluminum wire supplier.

Understanding MIG Welding for Aluminum

MIG welding utilizes a continuous wire feed to create a weld between aluminum sections. Unlike steel, aluminum is more sensitive to heat, which can lead to warping and distortion. Thus, selecting the right aluminum wire is crucial for achieving optimal results. Typically, aluminum MIG wires are made from alloys like 4043 and 5356—each designed for specific applications and offering different characteristics in terms of strength, corrosion resistance, and fluidity.

Key Factors in Selecting a MIG Welding Aluminum Wire Supplier

1. Quality of Wire The most critical factor when choosing a supplier is the quality of the aluminum wire they offer. High-quality wires are vital for producing strong, consistent welds. Look for suppliers who provide certification for their products, guaranteeing that their wires meet industry standards.

2. Range of Products A good supplier should offer a comprehensive range of aluminum welding wires. Different projects may require different alloys; hence, having various options enables you to select the best fit for your specific welding applications.

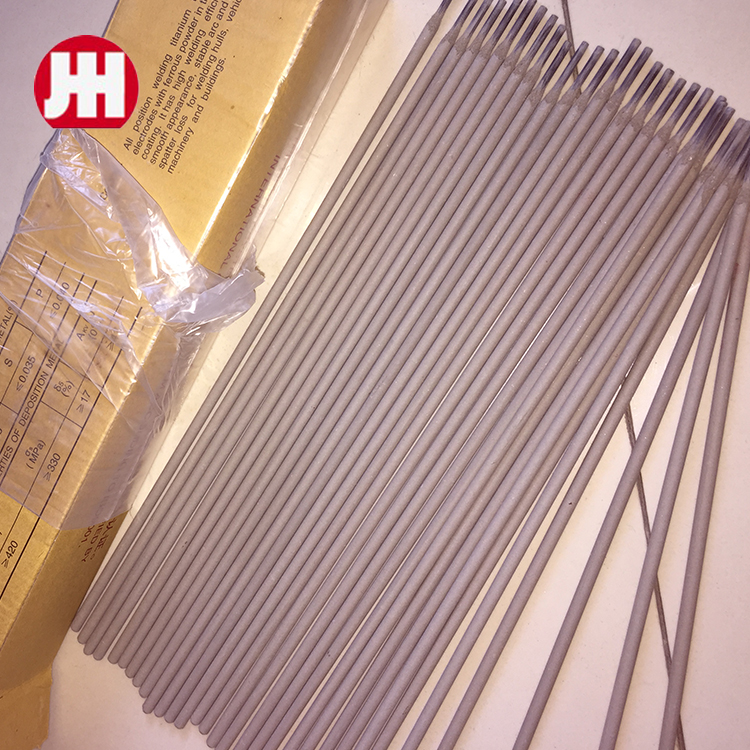

mig welding aluminum wire supplier

3. Technical Support Since the welding process can vary depending on the aluminum alloy, having a supplier that offers technical support is invaluable. They should be knowledgeable about their products and able to provide advice on choosing the right wire and equipment settings for your project.

4. Pricing and Availability Competitive pricing can determine your supplier choice, but it should not compromise quality. Additionally, ensure the supplier maintains good stock levels so you can get your materials promptly and minimize downtimes.

5. Reviews and Reputation Researching the supplier's reputation in the market is essential. Look for customer reviews and feedback regarding their products and services. A supplier with a solid reputation is more likely to deliver consistent quality and excellent customer service.

Conclusion

MIG welding aluminum wire suppliers play a crucial role in ensuring the success of aluminum welding projects. It's essential to take your time in selecting a supplier that prioritizes quality, offers a diverse range of products, provides technical support, and has a strong market reputation. By choosing the right supplier, you will not only enhance the quality of your welds but also streamline your welding processes, ultimately leading to more efficient and successful projects.

Investing effort in finding the best MIG welding aluminum wire supplier can significantly impact the outcome of your welding endeavors. Whether you are involved in automotive repair, construction, or manufacturing, having access to high-quality aluminum wire can make all the difference in achieving strong, reliable welds that stand the test of time.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025