stainless steel welding wire mig 316 supplier

Understanding Stainless Steel Welding Wire MIG 316 A Comprehensive Guide to Suppliers

When it comes to welding, selecting the right materials is crucial for ensuring the integrity and durability of the final product. One of the most popular types of welding wire used in the industry is stainless steel welding wire, particularly the MIG (Metal Inert Gas) method. Among the various grades available, 316 stainless steel welding wire is renowned for its excellent corrosion resistance and heat resistance properties, making it an ideal choice for various applications, from marine environments to food processing. This article provides a comprehensive overview of 316 stainless steel welding wire and tips on sourcing it from reliable suppliers.

What is 316 Stainless Steel?

316 stainless steel is an austenitic alloy known for its superior resistance to corrosion, particularly in chloride environments. It comprises iron, carbon, chromium, nickel, and molybdenum. The addition of molybdenum enhances corrosion resistance, making it suitable for harsh marine conditions. This alloy is commonly used in the construction of chemical processing equipment, marine components, and even medical devices, thanks to its non-reactive properties.

Why Choose MIG Welding?

MIG welding is a widely utilized welding technique, known for its speed and efficiency. It involves the continuous feeding of a wire electrode, which melts to form the weld pool, protected by an inert gas shield to prevent contamination. MIG welding is favored for stainless steel applications due to its ease of use and the ability to weld in various positions. Furthermore, it produces less spatter compared to other methods, resulting in cleaner welds, which is particularly important when working with high-quality materials like 316 stainless steel.

Characteristics of 316 Stainless Steel Welding Wire

1. Corrosion Resistance 316 welding wire provides excellent protection against various corrosive environments, making it suitable for use in chemical plants and marine applications.

2. High Temperature Resistance This wire can withstand high temperatures without compromising its mechanical properties, allowing it to be used in applications involving heat exposure.

stainless steel welding wire mig 316 supplier

4. Health and Safety When properly used, MIG welding with 316 wire minimizes health risks associated with harmful fumes, especially when welding inside confined spaces.

Choosing a Supplier

When sourcing 316 stainless steel welding wire, it’s essential to choose a reputable supplier to ensure that you receive high-quality materials. Here are some factors to consider

1. Reputation Look for suppliers with a strong industry reputation. Reviews and testimonials can give insights into their product quality and customer service.

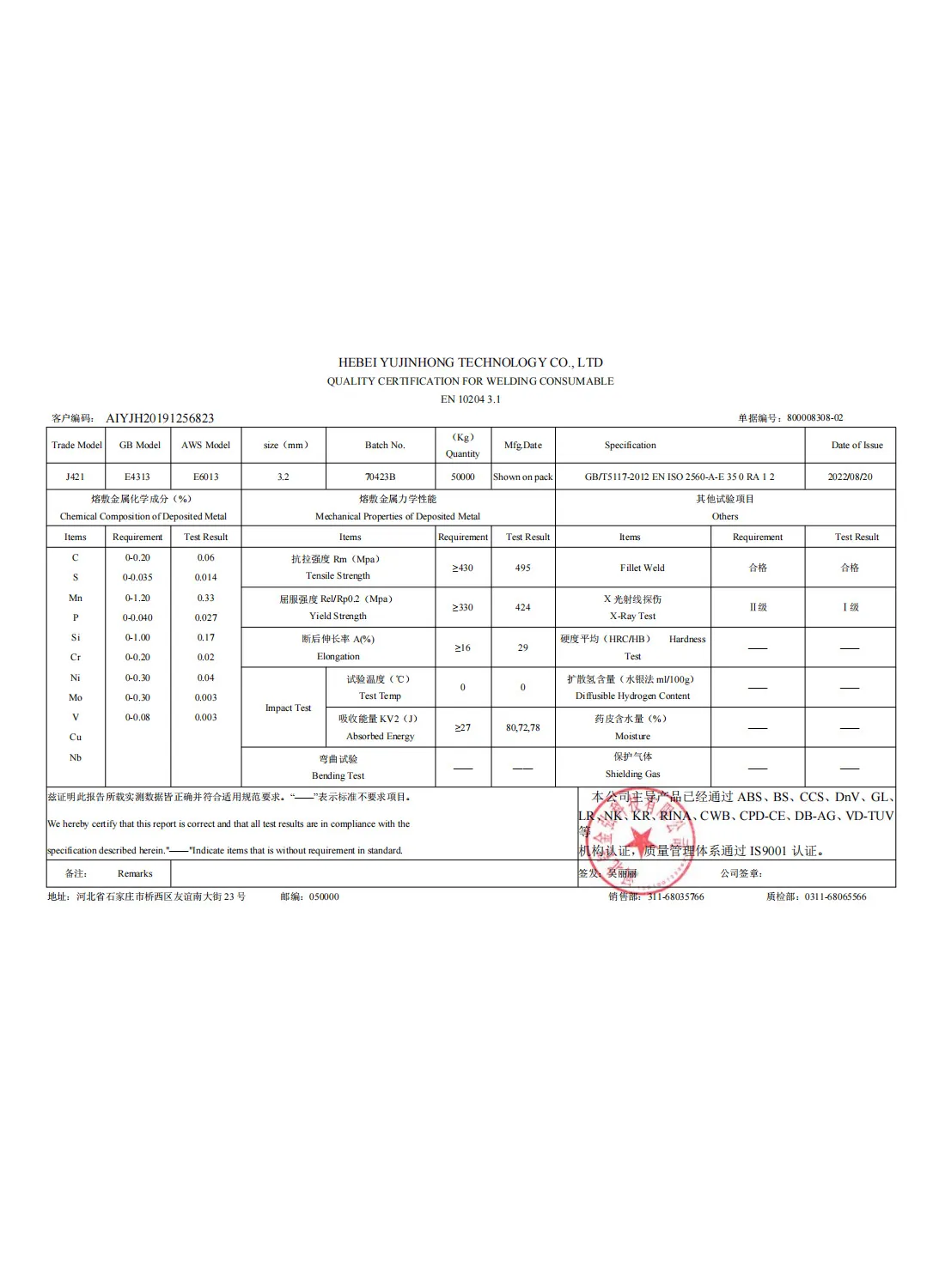

2. Certification Ensure that the supplier complies with relevant industry standards and certifications. This not only guarantees the quality of the wire but also ensures it meets safety requirements for specific applications.

3. Range of Products A good supplier should offer a wide variety of welding wires, including different diameters and spool sizes, allowing you to choose based on your specific project needs.

4. Customer Support Opt for suppliers that provide excellent customer service, including technical support and guidance on product usage. This can be especially important for projects requiring specific welding techniques.

5. Pricing While quality should be a priority, it’s also important to consider the pricing. Compare quotes from multiple suppliers to ensure you are getting a fair deal without compromising on quality.

Conclusion

Understanding the properties and applications of 316 stainless steel welding wire is crucial for anyone involved in welding and fabrication industries. Its superior corrosion resistance and high-temperature performance make it a go-to choice for demanding applications. When selecting suppliers, prioritize reputation, certifications, product range, customer support, and pricing to ensure you receive the best materials for your projects. With the right supplier and quality welding wire, you can ensure the success and longevity of your welding endeavors.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025