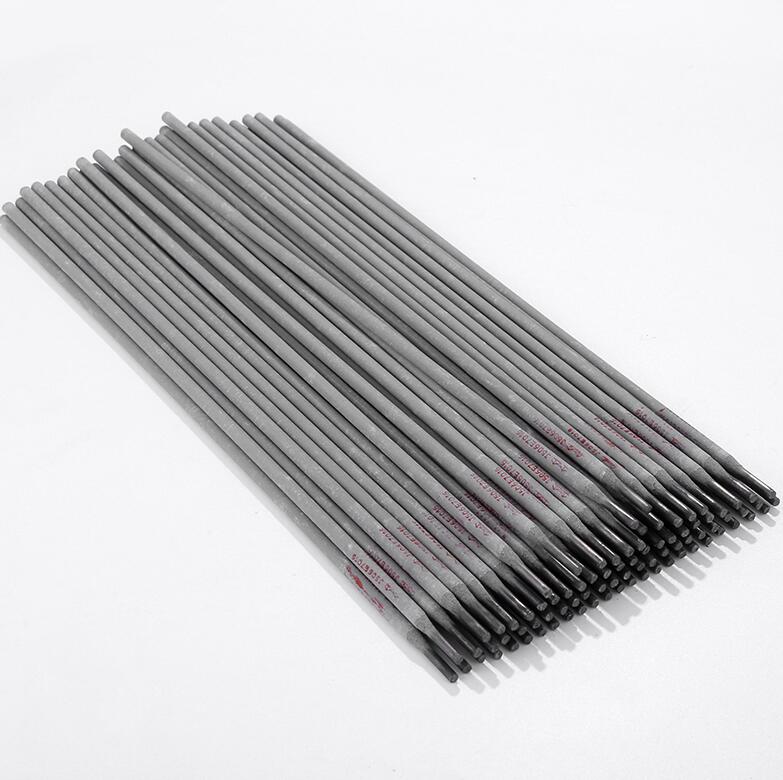

Wholesale 7018 Welding Rods for Quality Metal Fabrication and Construction Projects

The Role of Welding Rods in Industrial Applications A Detailed Overview of Wholesale 7018 Welding Rods

Welding is a crucial process in various industries, enabling the fusion of metals and the creation of strong, lasting structures. Among the plethora of welding rods available, the 7018 welding rod stands out for its unique characteristics and applications. This article will delve into the significance of wholesale 7018 welding rods, exploring their composition, benefits, and common uses in industrial settings.

Understanding the 7018 Welding Rod

The 7018 welding rod is a low-hydrogen electrode commonly used in the arc welding of mild steel. The designation 7018 signifies a specific classification according to the American Welding Society (AWS) standards the first two digits (70) indicate the minimum tensile strength of the weld metal (70,000 psi), while the 18 refers to the type of coating and its usability characteristics in welding positions.

These rods are typically manufactured with a mixture of iron powder and low-hydrogen coating, which helps to reduce the risk of hydrogen-induced cracking in the weld. The coating is essential as it creates a protective gas shield during the welding process, which prevents contamination from atmospheric conditions.

Benefits of 7018 Welding Rods

One of the primary benefits of using 7018 welding rods is their versatility. They can be used effectively in various positions, including flat, horizontal, vertical, and overhead welding. This adaptability makes them an excellent choice for both professional welders and industrial applications.

wholesale 7018 welding rod 1 8

Another advantage is their low-hydrogen characteristics. Hydrogen can be detrimental to the welding process, leading to weakness and potential failures in the welded joint. By minimizing hydrogen exposure, 7018 rods enhance the quality and durability of the welds, making them ideal for critical applications where the integrity of the structure is paramount.

Moreover, 7018 welding rods have excellent arc stability and smooth operation, providing a consistent and clean weld. They produce minimal spatter, which reduces the need for post-weld cleaning and improves efficiency in the welding process.

Industrial Applications

Wholesale 7018 welding rods are widely used in construction, manufacturing, and repair industries. Due to their strength and reliability, they are often employed in fabricating structures such as bridges, buildings, and pipelines. The 7018 rods are particularly favored in pipe welding and heavy machinery repair due to their ability to provide strong, long-lasting joints capable of withstanding stressful conditions.

Additionally, 7018 rods are commonly used in the automotive industry, particularly in the fabrication of frames and large components which demand high structural integrity. Their resistance to cracking and excellent mechanical properties make them suitable for high-stress applications.

Conclusion

In conclusion, wholesale 7018 welding rods play a vital role in modern welding practices across various industries. The combination of low-hydrogen characteristics, versatility, and the ability to produce strong, clean welds makes them an essential tool for welders. Whether for construction, manufacturing, or repair, the use of 7018 welding rods ensures that welds meet the highest standards of quality and durability. As industries continue to evolve, the demand for reliable welding materials like the 7018 welding rod will undoubtedly grow, reinforcing its importance in the world of fabrication and construction.

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025