1 月 . 13, 2025 11:53

Back to list

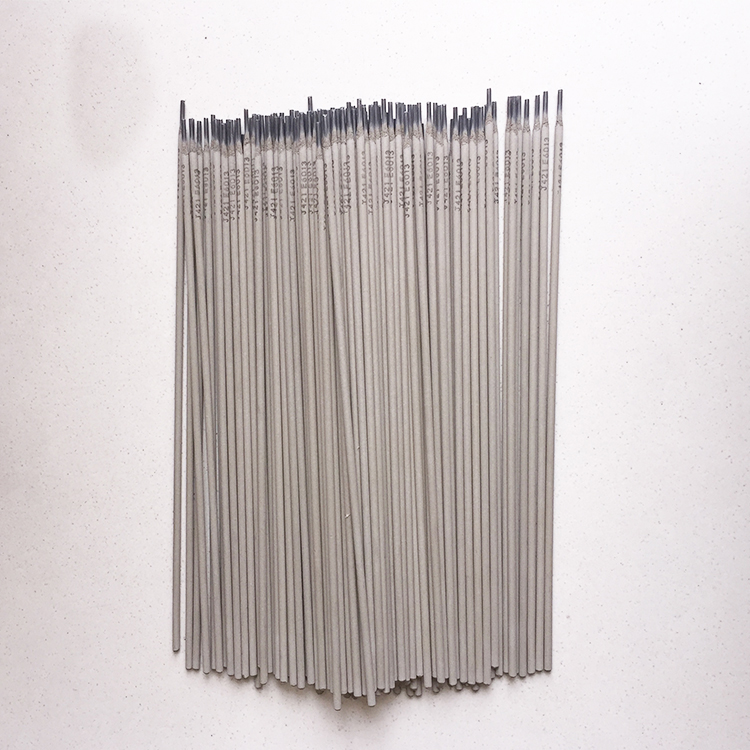

electrodo 1/16

Electrodes play a pivotal role in various industrial applications, innovating processes and ensuring efficient operation. When it comes to precision tasks such as welding or laboratory measurements, the choice of electrode size and composition is crucial. The 1/16 electrode is especially noteworthy due to its unique properties and versatility across applications.

In laboratory settings, the 1/16 electrode is used in various sensors and measuring devices due to its precision conductivity. For instance, in pH meters, small electrodes contribute to more accurate readings by minimizing interference and maintaining consistent response times. The electrode’s size and composition can affect the accuracy and longevity of measurements, hence why labs prioritize high-quality materials to ensure reliable data collection. Authoritativeness surrounding electrode technology is often derived from established industry standards and continual innovation within material sciences. Companies and professionals committed to maintaining superior quality often perform rigorous testing and adhere to specifications laid out by welding and electronics organizations. By ensuring that a 1/16 electrode meets these standards, manufacturers bolster its reputation and trustworthiness. Trustworthiness in tools like electrodes is built through consistent performance and the assurance of meeting task-specific requirements. This demands a combination of quality materials, precise manufacturing techniques, and expert recommendations. When a professional consistently experiences reliable outcomes with a 1/16 electrode, trust in its quality is naturally established, promoting repeated use and recommendation. In conclusion, the 1/16 electrode is a specialized tool that benefits a wide range of applications, from precise welding projects to accurate laboratory measurements. Through a deep understanding of its composition and practical application, professionals across various industries can leverage its unique advantages. As advancements continue, this electrode size is likely to retain its relevance, serving as a testament to its indispensable role in achieving meticulous results and maintaining quality control.

In laboratory settings, the 1/16 electrode is used in various sensors and measuring devices due to its precision conductivity. For instance, in pH meters, small electrodes contribute to more accurate readings by minimizing interference and maintaining consistent response times. The electrode’s size and composition can affect the accuracy and longevity of measurements, hence why labs prioritize high-quality materials to ensure reliable data collection. Authoritativeness surrounding electrode technology is often derived from established industry standards and continual innovation within material sciences. Companies and professionals committed to maintaining superior quality often perform rigorous testing and adhere to specifications laid out by welding and electronics organizations. By ensuring that a 1/16 electrode meets these standards, manufacturers bolster its reputation and trustworthiness. Trustworthiness in tools like electrodes is built through consistent performance and the assurance of meeting task-specific requirements. This demands a combination of quality materials, precise manufacturing techniques, and expert recommendations. When a professional consistently experiences reliable outcomes with a 1/16 electrode, trust in its quality is naturally established, promoting repeated use and recommendation. In conclusion, the 1/16 electrode is a specialized tool that benefits a wide range of applications, from precise welding projects to accurate laboratory measurements. Through a deep understanding of its composition and practical application, professionals across various industries can leverage its unique advantages. As advancements continue, this electrode size is likely to retain its relevance, serving as a testament to its indispensable role in achieving meticulous results and maintaining quality control.

Previous:

Latest news

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025

-

Premium Solid MIG Welding Wire - Strong, Low-Spatter WeldsNewsJul.21,2025