309 stainless stick rods

The modern marketplace offers a myriad of options for welding enthusiasts and professionals alike, but few tools prove as indispensable as the welding stick. A cornerstone of both hobbyist and industrial welding, the welding stick, also known as the stick electrode, stands as a testament to simplicity and efficacy in metal joining processes.

A key advantage of welding sticks lies in their versatility. Unlike some welding methods that necessitate the use of inert gases or specialized equipment, the stick welding technique can be employed in a wide array of environments. This adaptability makes it especially appealing to those operating in outdoor conditions or in regions where convenient access to additional welding resources is limited. The stick electrode's innate ability to function robustly even in less-than-ideal conditions strengthens its appeal to field welders and those engaged in complex, large-scale constructions.

From an expertise perspective, the stick method, also referred to as Shielded Metal Arc Welding (SMAW), embodies a preferred choice for welding professionals mindful of precise, reliable results. The variety of coatings on welding sticks allows for tailored applications, catering to different materials and structural needs. Whether dealing with high-carbon steel that demands particular care and control or standard mild steel, the breadth of options available in electrodes ensures that there is a perfect fit for every welding requirement.

In the spectrum of experience, it is proven that mastering the stick welding technique provides the welder with an invaluable skillset. Despite the rudimentary appearance, using a stick electrode requires a trained hand, as the welder must control the arc length effectively to ensure sound welds. Experienced welders tout the importance of practice in gaining proficiency, acknowledging that the feel of the electrode, the sound of the arc, and the pooling of the molten metal are all elements best learned firsthand.

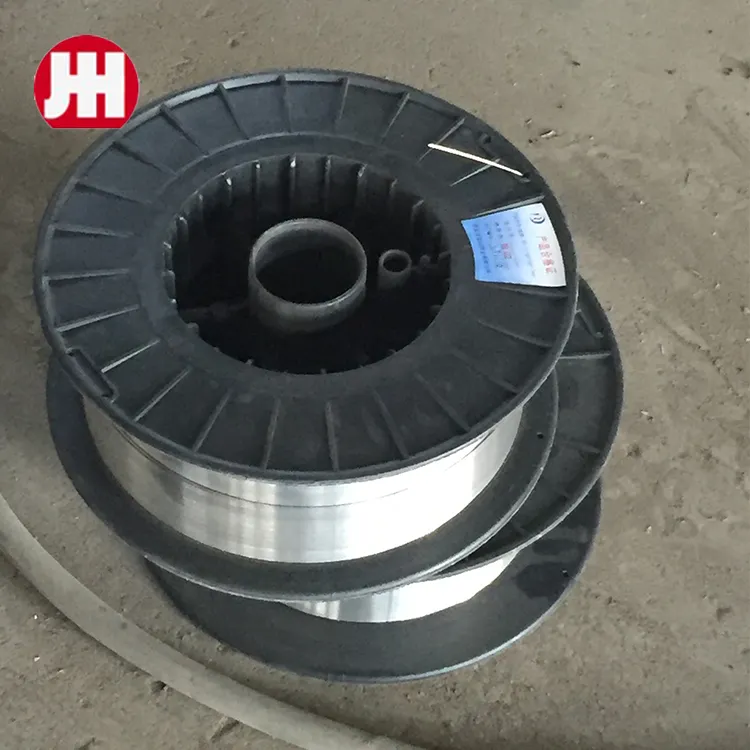

welding stick

Authoritativeness in the use of welding sticks is underscored by their widespread application in key industries such as construction, maintenance, and repair. Certified welding inspectors and industry experts often recommend stick welding for its deep penetration capabilities and strong welds, crucial for the integrity of joints in infrastructure projects and automotive repairs. Given its reliability, it is frequently taught in technical schools and vocational training programs as a foundational welding process.

Trustworthiness with welding rods extends into safety and cost-effectiveness. Stick welding equipment is notably more affordable than its TIG or MIG counterparts, providing a budget-friendly entry point for those starting their welding journey. Additionally, due to the nature of its consumable electrodes, stick welding typically generates less fume and requires fewer shielding elements, reducing environmental hazards and ensuring that usability is both safe and efficient.

In summary, the welding stick stands as more than just a tool—it embodies a blend of experience, expertise, authoritativeness, and trustworthiness that continues to serve as a pillar in the welding community. Its steadfast presence across diverse applications speaks to its enduring value, reliability, and efficiency in uniting metals across global industries. The journey of mastering stick welding not only equips professionals with a timeless technique but also fosters confidence in creating durable, high-quality welds essential for the construction of our world.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025