1 月 . 09, 2025 11:42

Back to list

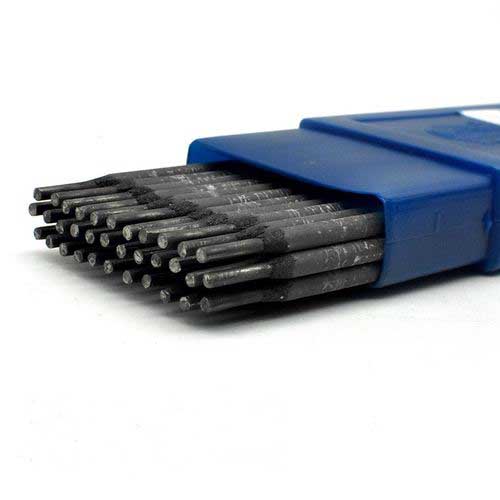

309 stainless stick rods

Choosing the right welding stick is crucial not only for achieving a high-quality weld but also for ensuring safety and efficiency in any welding project. In the dynamic world of welding, the experience of professionals who have refined their craft for decades provides invaluable insights. Expert welders understand that selecting the appropriate welding stick can dramatically affect the weld's strength, appearance, and durability.

Experience shared by seasoned welders often highlights nuanced differences that are not always apparent in specifications. For example, humidity can affect the weld quality, particularly with low-hydrogen electrodes like the E7018. Experienced welders understand the importance of proper electrode storage—using rod ovens to maintain dryness can prevent defects such as porosity or cracking in the weld. Additionally, the ease of handling a welding stick can affect a welder's precision and endurance. Smooth slag removal, minimal spatter, and consistent arc stability are critical characteristics that professionals look for in a quality electrode. A welder’s skill is magnified or hindered by the choice of welding stick, influencing the execution of their craft. In conclusion, the art of welding is an orchestration of experience, expertise, and the judicious selection of the right tools, with the welding stick being central to this process. It is a profound integration of practical knowledge, authoritative endorsements, and trustworthy product performance that ensures each weld passes the test of time and scrutiny. Whether undertaking structural projects or intricate designs, the welding stick stands as a testament to the welder's skill and the project's integrity. As technology and standards evolve, staying informed and choosing wisely reflect the principles at the heart of successful welding practices.

Experience shared by seasoned welders often highlights nuanced differences that are not always apparent in specifications. For example, humidity can affect the weld quality, particularly with low-hydrogen electrodes like the E7018. Experienced welders understand the importance of proper electrode storage—using rod ovens to maintain dryness can prevent defects such as porosity or cracking in the weld. Additionally, the ease of handling a welding stick can affect a welder's precision and endurance. Smooth slag removal, minimal spatter, and consistent arc stability are critical characteristics that professionals look for in a quality electrode. A welder’s skill is magnified or hindered by the choice of welding stick, influencing the execution of their craft. In conclusion, the art of welding is an orchestration of experience, expertise, and the judicious selection of the right tools, with the welding stick being central to this process. It is a profound integration of practical knowledge, authoritative endorsements, and trustworthy product performance that ensures each weld passes the test of time and scrutiny. Whether undertaking structural projects or intricate designs, the welding stick stands as a testament to the welder's skill and the project's integrity. As technology and standards evolve, staying informed and choosing wisely reflect the principles at the heart of successful welding practices.

Previous:

Latest news

-

Premium Carbon Rods for Welding | Stable Arc & Precise GougingNewsAug.27,2025

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025