2 月 . 16, 2025 00:04

Back to list

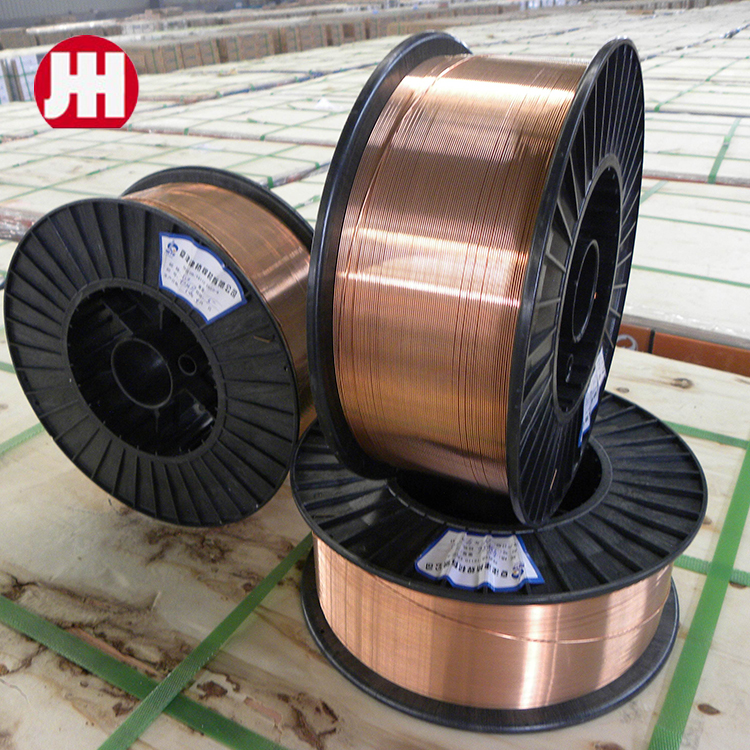

er70s-6 welding wire

When it comes to ensuring seamless welds in industrial applications, choosing the right welding wire is crucial. The ER70S-6 1.0mm welding wire stands out in the market, not only for its robust performance but also for its versatility across a spectrum of applications. For professionals navigating the wholesale market, understanding the nuances of this welding wire is essential for making informed purchasing decisions.

From an authoritative standpoint, ER70S-6 is produced under stringent quality controls, adhering to industry standards such as AWS A5.18 and ISO 14341. Distributors and manufacturers who engage in wholesale distribution of this wire often carry certifications that demonstrate compliance with these standards, further instilling confidence in buyers regarding the quality and consistency of the product they are investing in. On the trustworthiness scale, widespread testimonials from professionals across industries affirm the reliability of ER70S-6 1.0mm welding wire. Feedback often highlights the wire’s superior performance across diverse environments, validated by its frequent use in demanding applications. Earning trust from the welding community, the product continues to meet and exceed expectations, proving its worth as a staple in welding supply inventories. Investing in wholesale ER70S-6 1.0mm welding wire offers an excellent opportunity for businesses looking to maintain a steady supply of high-quality welding materials. The wholesale market provides competitive pricing options which, coupled with the durability and efficiency of the wire, translates into cost savings over time. Smart sourcing strategies from reputable suppliers, who can ensure timely deliveries and continuous availability of this essential product, are integral for businesses aiming to stay ahead in the competitive manufacturing landscape. In conclusion, ER70S-6 1.0mm welding wire remains a top choice for professionals requiring consistent performance and precision in their welding tasks. Its combination of technical superiority, adherence to standards, and positive industry reputation make it an invaluable component in the arsenal of any welding professional. For those looking to procure this wire on a wholesale basis, understanding these elements will enhance purchasing effectiveness and ensure they are acquiring a product that aligns with the stringent demands of their specific applications.

From an authoritative standpoint, ER70S-6 is produced under stringent quality controls, adhering to industry standards such as AWS A5.18 and ISO 14341. Distributors and manufacturers who engage in wholesale distribution of this wire often carry certifications that demonstrate compliance with these standards, further instilling confidence in buyers regarding the quality and consistency of the product they are investing in. On the trustworthiness scale, widespread testimonials from professionals across industries affirm the reliability of ER70S-6 1.0mm welding wire. Feedback often highlights the wire’s superior performance across diverse environments, validated by its frequent use in demanding applications. Earning trust from the welding community, the product continues to meet and exceed expectations, proving its worth as a staple in welding supply inventories. Investing in wholesale ER70S-6 1.0mm welding wire offers an excellent opportunity for businesses looking to maintain a steady supply of high-quality welding materials. The wholesale market provides competitive pricing options which, coupled with the durability and efficiency of the wire, translates into cost savings over time. Smart sourcing strategies from reputable suppliers, who can ensure timely deliveries and continuous availability of this essential product, are integral for businesses aiming to stay ahead in the competitive manufacturing landscape. In conclusion, ER70S-6 1.0mm welding wire remains a top choice for professionals requiring consistent performance and precision in their welding tasks. Its combination of technical superiority, adherence to standards, and positive industry reputation make it an invaluable component in the arsenal of any welding professional. For those looking to procure this wire on a wholesale basis, understanding these elements will enhance purchasing effectiveness and ensure they are acquiring a product that aligns with the stringent demands of their specific applications.

Previous:

Next:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025