Jan . 10, 2025 08:35

Back to list

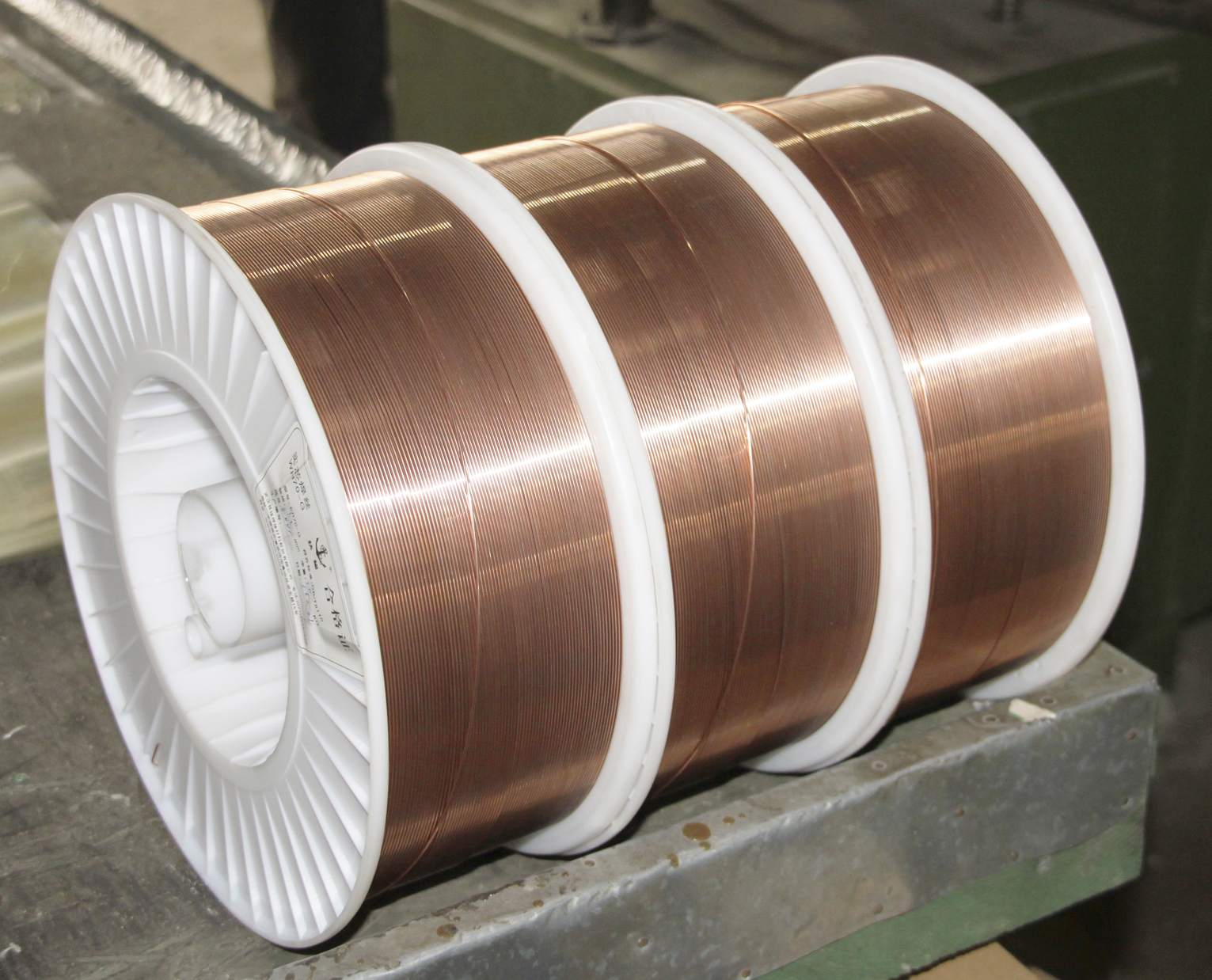

aluminum welding rod

Aluminum welding rods are an essential tool for both amateur and professional welders seeking to join aluminum materials effectively. The choice of the right welding rod is crucial for achieving strong, durable bonds. Understanding the nuances of aluminum welding rods can significantly enhance your welding projects, whether it be automotive repairs, crafting, or industrial applications.

Trustworthiness in aluminum welding projects is built through the reliability of the joints. Welders are encouraged to practice on scrap pieces to adjust parameters such as amperage and technique before working on the final piece. This practice not only builds confidence but also fine-tunes the skill required to handle these particular metals, an approach that reinforces trust in one’s ability to produce high-quality, enduring welds. Aluminum welding rods are often selected based on the welding method employed, such as MIG or TIG welding. TIG welding offers greater control, a feature particularly beneficial for thinner aluminum sheets or intricate joints. However, it requires a higher level of skill. MIG welding, while more accessible, may require adjustments in settings to accommodate the fast cooling nature of aluminum. Summing up the authoritative nature of aluminum welding rods, it is essential to source them from reputable manufacturers. Quality rods are ensured through certifications and adherence to industry standards, further guaranteeing the success of a welding project. Brands that offer consistency in their products' alloy composition and diameters notably increase the welder's capacity to produce satisfying results. Despite challenges, mastering the use of aluminum welding rods allows for the creation of robust and long-lasting welds. Whether enhancing structural integrity or achieving aesthetic excellence, the proper selection and technique application elevate the welding project’s outcome. With continual practice and adherence to detailed preparation and execution, welders can achieve professional-caliber results that ensure not only durability but also the trust of clients and peers alike.

Trustworthiness in aluminum welding projects is built through the reliability of the joints. Welders are encouraged to practice on scrap pieces to adjust parameters such as amperage and technique before working on the final piece. This practice not only builds confidence but also fine-tunes the skill required to handle these particular metals, an approach that reinforces trust in one’s ability to produce high-quality, enduring welds. Aluminum welding rods are often selected based on the welding method employed, such as MIG or TIG welding. TIG welding offers greater control, a feature particularly beneficial for thinner aluminum sheets or intricate joints. However, it requires a higher level of skill. MIG welding, while more accessible, may require adjustments in settings to accommodate the fast cooling nature of aluminum. Summing up the authoritative nature of aluminum welding rods, it is essential to source them from reputable manufacturers. Quality rods are ensured through certifications and adherence to industry standards, further guaranteeing the success of a welding project. Brands that offer consistency in their products' alloy composition and diameters notably increase the welder's capacity to produce satisfying results. Despite challenges, mastering the use of aluminum welding rods allows for the creation of robust and long-lasting welds. Whether enhancing structural integrity or achieving aesthetic excellence, the proper selection and technique application elevate the welding project’s outcome. With continual practice and adherence to detailed preparation and execution, welders can achieve professional-caliber results that ensure not only durability but also the trust of clients and peers alike.

Previous:

Next:

Latest news

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025