AWS 5.1 E7018 Electrodes – Low Hydrogen, High Strength

Aws 5.1 E7018 is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of welding materials. This article explores how HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Aws 5.1 E7018 Overview

- Benefits & Use Cases of Aws 5.1 E7018 in Manufacturing of welding materials

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Aws 5.1 E7018 from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

Aws 5.1 E7018 Overview

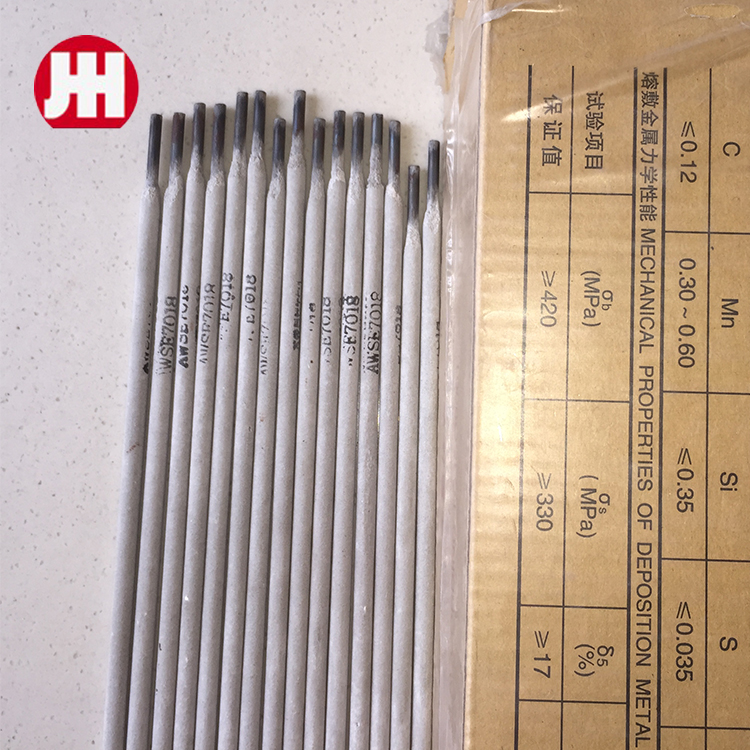

AWS A5.1 E7018 is a low-hydrogen, iron-powder coated carbon steel electrode engineered for code-quality welds in structural and pressure-related applications. Classified under the AWS A5.1 specification, E7018 is designed to deliver a minimum tensile strength of 70 ksi, excellent notch toughness, and high crack resistance, making it a mainstay for B2B decision makers in fabricated metal products and welding materials manufacturing. It is suitable for all-position welding (except vertical down), and typically runs on AC or DCEP. Typical diameters include 2.5 mm, 3.2 mm, 4.0 mm, and 5.0 mm, supporting a broad range of joint configurations and material thicknesses. For projects with enhanced toughness requirements, the AWS A5.1 E7018-1 variant is often preferred. In some catalogs and searches you may also see styles such as “aws a5 1 e7018 1” or even “.aws a5 1 e7018”; these refer to the same classification family. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. offers stable, consistent E7018 welding rods that meet classification requirements and support productivity on shop floors and field sites alike.

- Low-hydrogen coating minimizes diffusible hydrogen pickup to reduce cold cracking in restrained joints and thicker sections.

- Typical usability: AC or DCEP, smooth arc, easy slag removal, and refined bead appearance for code-critical work.

- Produced by HEBEI YUJINHONG TECHNOLOGY CO.,LTD., a professional supplier to the fabricated metal and welding materials sector.

Benefits & Use Cases of Aws 5.1 E7018 in Manufacturing of welding materials

Within Manufacturing of welding materials and fabricated metal products, E7018 is the workhorse electrode for structural steel fabrication, bridge building, ship modules, heavy equipment repair, and process-piping spools where low hydrogen is mandatory. In shop and field conditions, the electrode’s stable arc and low spatter profile support higher first-pass quality and reduce excessive grinding or rework. For colder climates or impact-critical components, many specifiers choose AWS A5.1 E7018-1 to achieve improved Charpy V-Notch toughness at lower temperatures. Decision makers evaluating solutions for mixed-power environments value the electrode’s AC/DCEP flexibility, which enables consistent performance with a wide range of power sources. Compared with rutile electrodes, E7018’s formulation prioritizes toughness and crack resistance, while its iron powder content supports high deposition rates and productivity. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. aligns its manufacturing and quality control to deliver consistent coating concentricity and arc stability, aiding repeatable operator performance and predictable bead shape. Whether you’re executing multi-pass groove welds on thick plate or routine fillets in coded structural work, Aws 5.1 E7018 remains a trusted choice for weld integrity, productivity, and compliance with common codes like AWS D1.1 for structural steel.

- Applications: structural frames, columns, stiffeners, earthmoving equipment, shipbuilding blocks, and general carbon steel fabrication.

- Advantages: low hydrogen, smooth arc, easy slag removal, refined bead profile, and strong mechanical properties.

- HEBEI YUJINHONG TECHNOLOGY CO.,LTD.: focused on dependable supply, consistent quality, and responsive service for B2B buyers.

Cost, Maintenance & User Experience

Total cost of ownership for Aws 5.1 E7018 extends beyond unit price to include productivity, defect rates, and the cost of rework. Low-hydrogen electrodes help curb hydrogen-induced cracking and porosity, cutting repair cycles and inspection delays—especially on thick or restrained weldments. With iron-powder coatings that support strong deposition rates, E7018 promotes faster fill in multi-pass grooves and consistent fillet sizing, improving throughput and ROI for fabrication shops. To preserve performance, moisture control is essential. Store opened electrodes in a rod oven (commonly 100–150°C / 212–302°F), and follow your WPS and manufacturer guidance for re-drying practices when needed. In the fabricated metal products sector, supervisors frequently report smoother restarts, reduced spatter cleanup, and more predictable bead geometry with quality E7018 rods, enhancing operator efficiency and weld aesthetics. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports these outcomes by offering reliably classified E7018 options that enable consistent arc behavior from batch to batch. For B2B buyers managing multiple projects, the combination of dependable weld quality, reduced rework, and efficient deposition contributes to a compelling payback profile across both shop and field applications.

- Lower rework risk and inspection holds due to low-hydrogen performance on code-critical joints.

- Better overall ROI driven by productivity, deposition efficiency, and stable arc starts and restarts.

Sustainability & Market Trends in manufacturing

Sustainability in welding increasingly focuses on reducing rework, consumable waste, and energy intensity while maintaining code compliance. With Aws 5.1 E7018, controlling hydrogen to prevent cracking directly reduces scrap and re-welding—both of which consume energy and materials. Shops are also optimizing oven practices and storage protocols to maintain electrode integrity without unnecessary energy use. From a market perspective, structural and infrastructure projects continue to drive demand for E7018 due to code-mandated low-hydrogen procedures, while the E7018-1 variant gains traction where impact toughness is specified. Regulatory expectations for fume extraction and operator safety remain front and center, pushing buyers toward stable, predictable consumables that help operators stay within procedure and finish first-pass welds correctly. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. positions itself as a forward-thinking partner by emphasizing dependable classification compliance, consistent performance, and support resources that help customers balance quality, productivity, and stewardship goals. As modernization accelerates across global fabrication markets, selecting reliable E7018 electrodes is a practical, immediate lever for improving environmental outcomes and meeting evolving specifications without disrupting established SMAW workflows.

- Trend: sustained demand for low-hydrogen SMAW in field and repair environments; growing usage of AWS A5.1 E7018-1 for tougher impact ratings.

- HEBEI YUJINHONG TECHNOLOGY CO.,LTD.: committed to reliable quality and customer support that align with productivity and sustainability objectives.

Conclusion on Aws 5.1 E7018 from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

For B2B leaders in fabricated metal products and welding materials, Aws 5.1 E7018 offers the right blend of mechanical strength, crack resistance, and productivity for code-critical carbon steel fabrication. From structural steel to heavy equipment repair and field work, E7018 remains a dependable choice that helps teams hit quality targets on schedule. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports these outcomes with reliably classified electrodes and responsive service tailored to professional users. Contact us: email: info@steeltoolschina.com. Visit our website: https://www.steeltoolschina.com

-

What is a medium-frequency pulse? What types of welding are suitable for?أخبارNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?أخبارNov.21,2025

-

Welding Knowledge 6أخبارNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?أخبارNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?أخبارNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016أخبارNov.17,2025