يناير . 09, 2025 10:38

Back to list

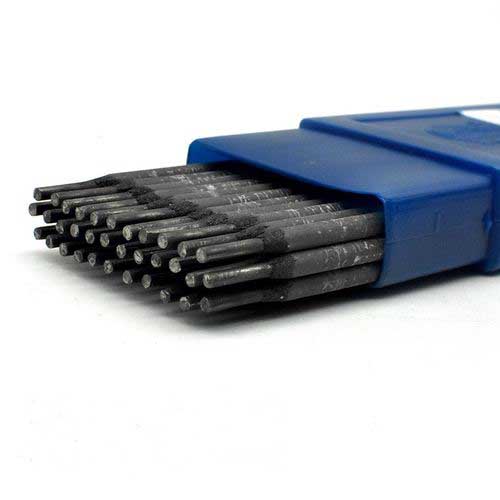

E6013 Welding Electrode Rods for carbon steel

Choosing the correct welding electrode is crucial in achieving strong, durable welds. With over two decades of experience in the welding industry, I've seen firsthand how the right electrode can make all the difference. This guide provides insights gleaned from years of practical work, ensuring you're equipped with the knowledge to select the best welding electrode for your projects.

In specialized environments, such as underwater or high-temperature settings, electrodes like E6013 and E6022 are utilized due to their adaptability and consistency under extreme conditions. Years of experience in these fields underline the importance of choosing electrodes tailored to specific environmental challenges. Understanding technological advancements, such as inverter technology vs. traditional transformers, is paramount, influencing electrode performance due to varied power outputs. As technology progresses, keeping up-to-date with these developments ensures that you select electrodes that complement modern welding equipment, reaffirming your expertise and trustworthiness in delivering quality results. Reliability in welding is not solely dependent on the tools and materials but also on the user's proficiency. Mastery over electrode usage is achieved by documented success across numerous welding tasks, endorsing your capability to counsel others on electrode selection for optimal outcomes. In conclusion, the authoritative selection of welding electrodes involves a blend of professional experience, specialized knowledge, and the foresight to adapt to technological innovations. It is this blend that inspires trust and delivers consistently high-quality welds across diverse projects.

In specialized environments, such as underwater or high-temperature settings, electrodes like E6013 and E6022 are utilized due to their adaptability and consistency under extreme conditions. Years of experience in these fields underline the importance of choosing electrodes tailored to specific environmental challenges. Understanding technological advancements, such as inverter technology vs. traditional transformers, is paramount, influencing electrode performance due to varied power outputs. As technology progresses, keeping up-to-date with these developments ensures that you select electrodes that complement modern welding equipment, reaffirming your expertise and trustworthiness in delivering quality results. Reliability in welding is not solely dependent on the tools and materials but also on the user's proficiency. Mastery over electrode usage is achieved by documented success across numerous welding tasks, endorsing your capability to counsel others on electrode selection for optimal outcomes. In conclusion, the authoritative selection of welding electrodes involves a blend of professional experience, specialized knowledge, and the foresight to adapt to technological innovations. It is this blend that inspires trust and delivers consistently high-quality welds across diverse projects.

Latest news

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025