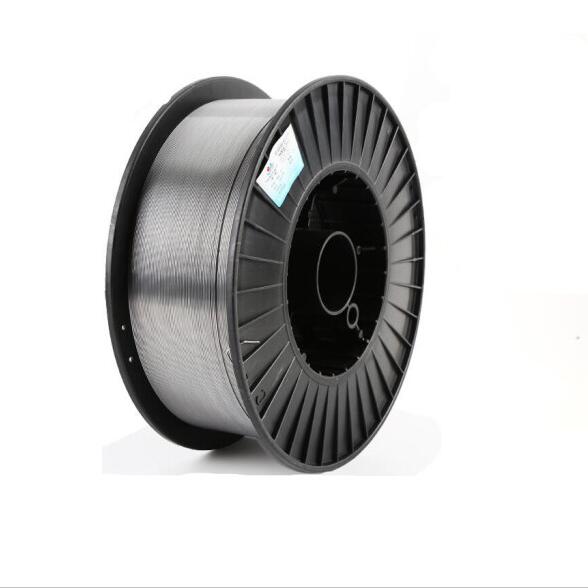

E71T-GS Welding Wire: Gasless Flux Core MIG Wire for All Positions

E71T-GS welding wire, also known as E71T-GS flux core or E71T-GS MIG wire, is a key solution in the manufacturing industry, specifically within Fabricated metal products and welding materials. This article explores how HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- E71T-GS Welding Wire, E71T-GS Flux Core, E71T-GS MIG Wire Overview

- Benefits & Use Cases of E71T-GS Welding Wire, E71T-GS Flux Core, E71T-GS MIG Wire in Welding Materials

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Manufacturing

- Conclusion on E71T-GS Welding Wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

E71T-GS Welding Wire, E71T-GS Flux Core, E71T-GS MIG Wire Overview

The E71T-GS classification represents a highly versatile self-shielded flux-cored arc welding (FCAW) wire, a cornerstone in modern manufacturing and the production of Fabricated metal products. This specialized welding material is designed primarily for single-pass applications on mild and low alloy steels, offering exceptional performance without the need for external shielding gas. Its unique formulation as an E71T-GS flux core wire makes it incredibly adaptable for various welding scenarios, from general fabrication to structural repairs. The inherent self-shielding properties of E71T-GS welding wire ensure stable arc performance and excellent bead appearance, even in less-than-ideal conditions such as windy outdoor environments.

For B2B decision-makers in the welding materials sector, understanding the technical specifications of solutions like E71T-GS MIG wire is crucial. It typically operates on DCEN (Direct Current Electrode Negative) polarity, facilitating deep penetration and strong, reliable welds. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. stands as a premier manufacturer, dedicated to producing superior E71T-GS welding wire that consistently meets stringent industry standards for quality and performance. Our commitment ensures that businesses can rely on our products for critical applications, delivering robust and efficient welding solutions across their operations.

Benefits & Use Cases of E71T-GS Welding Wire, E71T-GS Flux Core, E71T-GS MIG Wire in Welding Materials

The advantages of utilizing E71T-GS welding wire are significant for operations within the Fabricated metal products and general manufacturing sectors. A primary benefit is its self-shielded nature, eliminating the need for bulky and costly shielding gas cylinders. This not only reduces operational expenses but also enhances portability, making E71T-GS flux core an ideal choice for field repairs, remote job sites, and situations where gas supply is impractical or difficult. Its capability to perform effectively in various positions, often including overhead and vertical-up, offers unmatched versatility for complex fabrication tasks.

Specific use cases for E71T-GS MIG wire extend across diverse applications, from light structural steel fabrication and general shop work to the repair of agricultural equipment and automotive components. The wire's ability to tolerate slight surface contaminants like rust or paint makes it incredibly forgiving and efficient for real-world welding materials applications, minimizing pre-weld preparation time. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. prides itself on its deep expertise in the welding materials sector, ensuring that our E71T-GS welding wire offers superior arc stability, minimal spatter, and consistent weld quality. This commitment translates into increased productivity and reduced rework for our B2B partners, providing a distinct competitive advantage in their manufacturing processes.

Cost, Maintenance & User Experience

Investing in high-quality welding materials like E71T-GS welding wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD. offers compelling advantages in terms of total cost of ownership (TCO) and return on investment (ROI). The absence of external shielding gas translates directly into lower consumables costs and eliminates gas cylinder rental fees, providing substantial long-term savings for businesses in the Fabricated metal products sector. Furthermore, the inherent durability of welds made with E71T-GS flux core reduces the likelihood of costly reworks and structural failures, extending the lifespan of fabricated components and assemblies.

User experience with our E71T-GS MIG wire consistently receives positive feedback from welders. Its forgiving nature, excellent arc stability, and manageable spatter contribute to a smoother, more efficient welding process. This ease of use not only reduces training time for new operators but also enhances productivity for experienced professionals, allowing them to complete projects faster and with greater precision. Our clients in manufacturing report significant improvements in operational efficiency and weld integrity, underpinning the value proposition of HEBEI YUJINHONG TECHNOLOGY CO.,LTD.'s premium welding solutions. The robust performance and minimal maintenance requirements of our E71T-GS welding wire further contribute to its appeal as a reliable and cost-effective choice.

Sustainability & Market Trends in Manufacturing

In today's evolving manufacturing landscape, sustainability and operational efficiency are no longer just buzzwords—they are critical drivers for B2B decision-makers. The E71T-GS welding wire aligns perfectly with these market trends. By eliminating the need for shielding gas, E71T-GS flux core contributes to a reduced carbon footprint, as it negates the energy consumption associated with gas production, transportation, and storage. This makes it an environmentally conscious choice for companies aiming to meet increasingly stringent environmental regulations and corporate sustainability goals within the Fabricated metal products industry.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. is at the forefront of this shift, continuously innovating our welding materials to offer solutions that are both high-performing and eco-friendly. Our E71T-GS MIG wire is a testament to our commitment to forward-thinking manufacturing practices. We understand that our partners require products that not only deliver exceptional results but also support their broader sustainability initiatives. As the demand for efficient, versatile, and environmentally responsible welding solutions grows, HEBEI YUJINHONG TECHNOLOGY CO.,LTD. remains dedicated to providing cutting-edge E71T-GS welding wire that helps businesses thrive while upholding their environmental responsibilities. Our focus on quality and innovation ensures we lead the way in sustainable welding technology.

Conclusion on E71T-GS Welding Wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

The E71T-GS welding wire, including its variations like E71T-GS flux core and E71T-GS MIG wire, stands out as an indispensable solution for modern manufacturing, particularly within the demanding realm of Fabricated metal products and specialized welding materials. Its unparalleled versatility, cost-effectiveness, and ease of use make it a superior choice for businesses seeking to enhance productivity, ensure weld integrity, and achieve significant operational savings. From reducing reliance on shielding gas to offering robust performance in challenging environments, E71T-GS welding wire delivers consistent excellence.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. is proud to be a trusted provider of high-quality E71T-GS welding wire, backed by our unwavering commitment to innovation and customer satisfaction. We empower B2B decision-makers with the reliable, high-performance welding materials needed to excel in a competitive market. Choose HEBEI YUJINHONG TECHNOLOGY CO.,LTD. for welding solutions that drive efficiency, durability, and sustainable growth.

Contact us: email: info@steeltoolschina.com

Visit our website: https://www.steeltoolschina.com

-

What is a medium-frequency pulse? What types of welding are suitable for?VijestiNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?VijestiNov.21,2025

-

Welding Knowledge 6VijestiNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?VijestiNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?VijestiNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016VijestiNov.17,2025