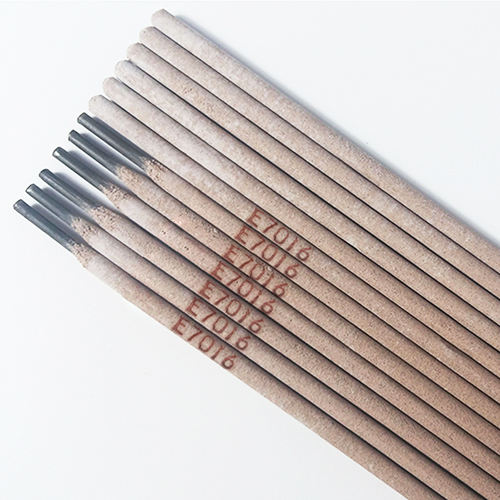

Premium E7016 Welding Rods: High Strength & All-Position

The Advanced Engineering of Low-Hydrogen Welding: Focusing on e7016 welding rods

In the demanding landscape of industrial fabrication and construction, the selection of appropriate welding consumables is paramount to ensuring structural integrity, operational longevity, and cost-efficiency. Among the various classifications, electrode 7016 stands out as a critical choice for high-strength, low-alloy steels where exceptional weld metal toughness and crack resistance are non-negotiable. These specialized electrodes are designed to deposit weld metal with superior mechanical properties, making them indispensable in applications ranging from critical pressure vessels to heavy machinery components.

The unique formulation of e7016 welding rods minimizes hydrogen content in the weld metal, a crucial factor in preventing hydrogen-induced cracking—a common failure mechanism in many high-strength steel applications. This attribute, combined with excellent arc stability and puddle control, empowers welders to achieve high-quality, defect-free welds even in challenging positions. As industries continue to push the boundaries of material science and structural design, the demand for reliable, high-performance welding solutions like the e7016 welding rod only intensifies. This comprehensive overview delves into the technical intricacies, manufacturing excellence, diverse applications, and strategic advantages offered by these indispensable welding consumables, including opportunities for customized solutions that address specific project demands.

Understanding E7016 Welding Rods: Technical Specifications and Industry Standards

The AWS A5.1/A5.1M specification classifies e7016 welding rods as low-hydrogen potassium type electrodes, signifying their ability to produce weld deposits with excellent impact toughness at low temperatures and high resistance to cracking. The "70" indicates a minimum tensile strength of 70,000 psi, while the "1" denotes that it can be used in all welding positions (flat, horizontal, vertical, and overhead). The "6" identifies it as a low-hydrogen potassium type, suitable for AC or DC reverse polarity (DCEP) current, and known for its strong arc force and moderate penetration.

The coating of an electrode 7016 is rich in deoxidizers and slag formers, which protect the molten weld pool from atmospheric contamination and help in refining the grain structure of the weld metal. This advanced formulation is crucial for achieving the desired mechanical properties and ensuring robust, long-lasting connections. Strict adherence to manufacturing standards and material selection is vital to maintaining these characteristics, ensuring that each e7016 welding rod performs consistently under demanding conditions.

Key Technical Parameters for E7016 Welding Rods

| Characteristic | Specification / Range | Standard |

|---|---|---|

| Vlačna čvrstoća | ≥ 490 MPa (70 ksi) | AWS A5.1 |

| Čvrstoća popuštanja | ≥ 400 MPa (58 ksi) | AWS A5.1 |

| Elongacija | ≥ 22% | AWS A5.1 |

| Impact Toughness (Charpy V-notch) | ≥ 27 J at -29°C (-20°F) | AWS A5.1 |

| Typical Chemical Composition (Weld Metal %) | C: 0.05-0.10, Mn: 0.9-1.2, Si: 0.4-0.6, P: <0.025, S: <0.025 | AWS A5.1 |

| Hydrogen Content (Diffusible H2) | < 8 ml/100g weld metal (HDM) | ISO 3690 / AWS A4.3 |

| Recommended Current | AC or DC+ (Reverse Polarity) | Manufacturer Spec |

These specifications underline the performance capabilities of the e7016 welding rod, making it a preferred choice for welding carbon and low-alloy steels in critical applications where a combination of high strength, ductility, and crack resistance is essential. The low hydrogen content is particularly vital in preventing delayed cracking in susceptible materials, contributing significantly to the overall service life and reliability of welded structures.

The Meticulous Manufacturing Process of E7016 Welding Rods

The production of high-quality e7016 welding rods is a complex, multi-stage process that demands precision engineering and stringent quality control at every step. From raw material sourcing to final packaging, each phase is critical to ensuring the consistent performance and reliability of the finished electrodes. Understanding this process provides insight into the expertise and technology required to produce a product that meets global industry standards like ISO, AWS, and JIS.

Process Flow Overview:

- 1. Raw Material Procurement & Inspection:

The core wire, typically a mild steel wire (e.g., carbon steel wire rod), is procured from certified suppliers. It undergoes rigorous chemical analysis and mechanical testing to ensure it meets specifications for purity and consistency. Flux materials—including cellulose, rutile, iron powder, and deoxidizers—are also carefully selected and tested for composition, particle size, and moisture content. The precise control over these base materials is fundamental for achieving the desired weld metal properties of the electrode 7016.

- 2. Core Wire Preparation:

The core wire is straightened, cut to specific lengths, and mechanically cleaned to remove any surface contaminants, rust, or drawing lubricants. This ensures optimal adhesion of the flux coating and prevents impurities from entering the weld pool.

- 3. Flux Mixing and Blending:

The various flux components are accurately weighed and thoroughly blended in precise ratios according to proprietary formulations. A binder (e.g., sodium silicate, potassium silicate) is added to create a cohesive paste. This step is crucial for defining the arc characteristics, slag properties, and the final mechanical and chemical properties of the deposited weld metal.

- 4. Extrusion and Coating:

The prepared flux mixture is then hydraulically extruded onto the core wire. This process applies a uniform, concentric coating of flux to the wire. Sophisticated CNC machinery ensures consistent coating thickness and concentricity, which directly impacts the electrode's performance, arc stability, and usability.

- 5. Drying and Baking (Low-Hydrogen Treatment):

This is arguably the most critical stage for e7016 welding rods. The coated electrodes are carefully dried at controlled temperatures to remove initial moisture, then subjected to high-temperature baking in specialized ovens (typically 350-450°C for several hours). This baking process thoroughly removes moisture from the flux coating, achieving the extremely low hydrogen levels (<8ml/100g) characteristic of low-hydrogen electrodes, essential for preventing hydrogen embrittlement in the final weld. Strict adherence to ISO 2560 and AWS A5.1 guidelines for moisture content is maintained.

- 6. Tip Cleaning and Branding:

After baking, the arc striking end of each electrode is cleaned to expose the bare core wire, ensuring a reliable arc ignition. Electrodes are then branded with product information, including AWS classification and size.

- 7. Final Inspection & Quality Control:

A comprehensive final inspection includes visual checks for coating defects, dimensional accuracy, and concentricity. Destructive testing involves actual welding tests to verify mechanical properties (tensile strength, yield strength, elongation, impact toughness) and chemical composition of the weld metal. Tests are conducted according to ISO 9001, AWS A5.1, and JIS Z 3211 standards. This rigorous testing ensures that the final product meets or exceeds all specified technical parameters and performs as expected in challenging industrial environments, contributing to an extended service life in target industries such as petrochemical, metallurgy, and water supply & drainage, where advantages like energy saving and corrosion resistance are vital.

- 8. Packaging:

Finished electrodes are hermetically sealed in moisture-proof packaging (e.g., vacuum-sealed foil bags or moisture-resistant cardboard boxes) to prevent re-absorption of moisture and maintain their low-hydrogen characteristics during storage and transport. Proper storage is crucial to preserve the integrity of the e7016 welding rod until it is used.

Key Technical Advantages and Performance Excellence of E7016 Electrodes

The distinct formulation and manufacturing precision of e7016 welding rods imbue them with a suite of technical advantages that make them superior for critical applications. These advantages translate directly into enhanced weld quality, increased structural integrity, and long-term reliability for welded components across various industries.

- Superior Crack Resistance: The primary advantage lies in their low-hydrogen coating, which significantly reduces the risk of hydrogen-induced cracking (HIC) or delayed cold cracking. This is crucial when welding high-strength steels or thick sections where residual stresses are high.

- Excellent Mechanical Properties: Weld deposits from electrode 7016 exhibit high tensile strength, yield strength, and exceptional impact toughness, even at sub-zero temperatures. This makes them ideal for structures subjected to dynamic loads, vibrations, or cold environments.

- All-Positional Weldability: Despite their robust metallurgical properties, these electrodes offer excellent usability in all welding positions (flat, horizontal, vertical-up, overhead), providing flexibility for complex fabrication and repair tasks.

- Stable Arc and Good Puddle Control: The potassium-based flux provides a smooth, stable arc, facilitating easier manipulation of the weld puddle. This results in consistent bead appearance and minimizes welding defects.

- Enhanced Corrosion Resistance: For specific applications, the weld metal deposited can contribute to the overall corrosion resistance of the fabricated structure, particularly when welding certain alloyed steels used in aggressive environments.

- Energy Saving: Modern e7016 welding rods are often designed for efficient energy transfer, contributing to optimized welding parameters and potentially reducing energy consumption during extended welding operations.

- Radiographic Quality Welds: With proper welding techniques, e7016 welding rods consistently produce welds that pass stringent radiographic inspection, confirming their internal soundness and freedom from porosity or inclusions.

These advantages underscore why `Customized E7016 Welding Rods Electrodes` are not merely consumables but critical components in ensuring the safety, durability, and performance of high-value industrial assets. The commitment to delivering electrodes that consistently meet these high standards is a testament to advanced metallurgical engineering.

Application Scenarios and Target Industries for E7016 Welding Rods

The robust characteristics of e7016 welding rods make them indispensable across a broad spectrum of heavy industries where structural integrity and resistance to extreme conditions are paramount. Their versatility and superior performance enable critical applications in demanding environments, ensuring long-term operational reliability.

Primary Target Industries:

- Petrochemical Industry: Used extensively in the fabrication and repair of pressure vessels, storage tanks, pipelines, and heat exchangers that operate under high pressure, high temperature, and corrosive environments. The low hydrogen property is vital here to prevent cracking in sensitive steels.

- Power Generation (Thermal, Nuclear): Critical for welding boiler components, turbine casings, structural supports, and other vital infrastructure where high-temperature strength, creep resistance, and safety are paramount.

- Heavy Machinery and Equipment Manufacturing: Employed in fabricating heavy-duty frames, excavator arms, crane components, agricultural machinery, and mining equipment, where high impact resistance and fatigue strength are required.

- Shipbuilding and Offshore Structures: Essential for constructing hull sections, decks, offshore platforms, and marine equipment that must withstand harsh marine environments, dynamic loads, and low-temperature conditions.

- Bridge and Infrastructure Construction: Utilized for welding critical joints in bridges, high-rise buildings, and other civil engineering projects where robust structural integrity and longevity are fundamental.

- Water Supply & Drainage Systems: For pipelines, pumps, and structural components requiring strong, corrosion-resistant welds to ensure reliable and long-lasting water infrastructure.

Typical Application Scenarios:

- Welding High-Strength Low-Alloy (HSLA) Steels: These steels are commonly used for their strength-to-weight ratio, and electrode 7016 is perfectly suited to maintain their mechanical properties post-welding.

- Thick Section Welding: For components with significant thickness, where higher preheat temperatures and careful control of interpass temperatures are required, e7016 welding rods minimize the risk of hydrogen embrittlement.

- Repair and Maintenance: Ideal for critical repairs of existing structures and equipment where matching the original material's properties and ensuring reliability are crucial.

- Root Pass Welding: The stable arc and deep penetration characteristics make it suitable for root passes, especially in pipe welding, ensuring full penetration and strong foundations for subsequent passes.

The versatility and dependable performance of e7016 welding rods are critical enablers for modern industrial fabrication, contributing to the safety and longevity of infrastructure and machinery globally.

Industry Trends and Market Outlook for Low-Hydrogen Electrodes

The welding consumables market, particularly for low-hydrogen electrodes like e7016 welding rods, is continually evolving, driven by advancements in material science, increasing demands for structural integrity, and stricter regulatory standards. Several key trends are shaping the future of this sector:

- Increasing Demand for High-Strength Steels: As industries like automotive, construction, and energy seek lighter yet stronger materials, the use of high-strength, low-alloy (HSLA) steels is growing. This directly fuels the demand for low-hydrogen electrodes capable of welding these advanced materials without defects.

- Focus on Automation and Robotics: While SMAW (Shielded Metal Arc Welding) is manual, the trend towards automation in welding influences the demand for more consistent and defect-free consumables. Manufacturers are working on enhancing the arc characteristics and performance consistency of electrode 7016 to support highly skilled manual welders performing critical, often non-automatable, tasks.

- Environmental and Sustainability Initiatives: There's a growing emphasis on reducing welding fumes and improving energy efficiency. Manufacturers are exploring flux formulations that produce less smoke and spatter, and consumables that contribute to less energy consumption per weld pass.

- Customization and Specialty Formulations: As applications become more specialized, the need for customized e7016 welding rods—tailored for specific alloys, service temperatures, or environmental conditions—is on the rise. This allows for optimized performance and cost-effectiveness in niche applications.

- Enhanced Traceability and Quality Assurance: With stricter international standards and liability concerns, manufacturers are investing in advanced quality control systems, ensuring complete traceability of raw materials and finished products. Certifications like ISO 9001 and adherence to AWS A5.1 are becoming non-negotiable.

- Growth in Infrastructure Projects: Global investments in infrastructure (bridges, pipelines, power plants) continue to drive substantial demand for high-quality welding consumables, where the durability and reliability provided by e7016 welding rod are highly valued.

These trends highlight a market that prioritizes quality, reliability, and adaptability. Suppliers who can offer robust products, alongside specialized knowledge and customized solutions, are best positioned to meet the evolving needs of industrial clients. The enduring importance of low-hydrogen properties ensures that the e7016 welding rod will remain a cornerstone in critical welding applications.

Customized Solutions for E7016 Welding Rods Electrodes

While standard e7016 welding rods offer exceptional performance, many specialized projects and unique industrial applications demand tailored solutions. Customization allows for the fine-tuning of electrode properties to perfectly match the specific metallurgical, operational, and environmental requirements of a given welding task. This bespoke approach ensures optimal weld quality, maximized efficiency, and reduced risk in complex scenarios.

Areas of Customization:

- Alloy Composition of Weld Metal: Adjustments can be made to the flux components to slightly modify the chemical composition of the deposited weld metal, aligning it more closely with specific base metals or desired post-weld properties (e.g., enhanced corrosion resistance, specific mechanical strength targets).

- Coating Thickness and Concentricity: While standard electrodes have specified tolerances, specialized applications might benefit from slightly altered coating thickness for different arc characteristics or specific positional welding requirements.

- Electrode Diameter and Length: Beyond standard sizes, custom diameters and lengths can be produced to accommodate unique joint designs, limited access, or specialized welding equipment, enhancing welder ergonomics and efficiency.

- Diffusible Hydrogen Levels: For extremely sensitive applications, further reductions in diffusible hydrogen beyond standard AWS classifications can be achieved through ultra-low moisture flux formulations and specialized baking processes.

- Packaging Solutions: Custom packaging, such as specific bundle sizes, specialized moisture barriers, or larger container111s for automated feeding systems, can optimize logistics and storage for large-scale projects.

Our expertise in manufacturing e7016 welding rods allows us to collaborate closely with clients to develop electrodes that precisely meet their unique project specifications. This consultative approach, leveraging our R&D capabilities and adherence to global standards, ensures that even the most challenging welding requirements are met with bespoke, high-performance solutions. By customizing, clients can often achieve superior mechanical properties, extend the service life of their welded components, and optimize their welding processes for significant cost savings.

Vendor Comparison and Selection Criteria for E7016 Electrodes

Choosing the right supplier for e7016 welding rods is as crucial as selecting the electrodes themselves. The quality, consistency, and support provided by a vendor directly impact project success, operational efficiency, and long-term structural integrity. A careful evaluation process is essential to ensure you partner with a provider who meets your technical and logistical requirements.

Comparison Table: Generic vs. High-Quality vs. Customized E7016 Rods

| Feature | Generic E7016 | High-Quality E7016 | Customized E7016 |

|---|---|---|---|

| Compliance | Meets minimum AWS A5.1 | Exceeds AWS A5.1, ISO, JIS | Tailored to specific project standards |

| Consistency | Variable batch to batch | High, reliable performance | Exceptional, precisely controlled |

| Mechanical Properties | Meets baseline (e.g., 70 ksi TS) | Superior (e.g., higher impact strength) | Optimized for specific strength/toughness |

| Hydrogen Content | Standard low-hydrogen | Consistently very low (<5ml/100g) | Ultra-low for critical applications |

| Technical Support | Limited or basic | Comprehensive application engineering | Dedicated R&D, metallurgical expertise |

| Cost | Lower initial cost | Moderate, value-driven | Higher initial, optimized long-term value |

Key Selection Criteria for a Vendor:

- Certifications and Compliance: Ensure the vendor’s products are certified to relevant international standards (AWS A5.1, ISO 2560, CE, TÜV). Verify their own quality management systems (e.g., ISO 9001).

- Manufacturing Expertise: Inquire about their manufacturing process, quality control protocols, and the technology they employ (e.g., CNC machining for extrusion, advanced baking ovens).

- Reputation and Track Record: Look for vendors with a proven history of supplying reliable products, positive customer feedback, and long-standing partnerships with reputable clients.

- Technical Support and R&D Capabilities: A strong vendor offers more than just products; they provide expert technical advice, problem-solving support, and the capacity for R&D to develop customized solutions.

- Supply Chain Reliability: Evaluate their logistics, lead times, and ability to ensure consistent supply, especially for large or critical projects.

- Value Proposition: While cost is a factor, prioritize the overall value, considering product performance, reliability, support, and the potential for reduced rework and improved structural longevity.

By meticulously evaluating these criteria, businesses can select a vendor for e7016 welding rods that not only provides superior products but also acts as a strategic partner in achieving welding excellence and project success. Our commitment to quality, backed by years of service and extensive certifications, positions us as a trusted partner for even the most demanding welding requirements.

Real-World Application Case Studies with E7016 Welding Rods

The performance of e7016 welding rods is best illustrated through their successful deployment in real-world industrial projects. These case studies highlight their reliability, efficiency, and ability to overcome complex welding challenges, contributing significantly to project timelines and structural longevity.

Case Study 1: High-Pressure Pipeline Fabrication in the Petrochemical Sector

A major petrochemical client was undertaking the expansion of a crude oil refinery, which involved fabricating several kilometers of high-pressure pipelines. These pipelines, constructed from API 5L X65 grade steel, required welds with exceptional strength, ductility, and resistance to hydrogen-induced cracking, especially in sub-zero operational temperatures common in certain regions. The project engineers specified low-hydrogen electrodes for all critical joints.

- Challenge: Ensuring radiographic quality welds on thick-walled pipes in various positions, minimizing downtime, and preventing defects that could lead to catastrophic failures.

- Solution: Our e7016 welding rods were chosen due to their proven track record of consistent low hydrogen levels and superior mechanical properties. Welders appreciated the stable arc and manageable slag, which contributed to high deposition rates and reduced cleanup.

- Outcome: Over 98% of the welds passed initial radiographic inspection, significantly reducing rework and accelerating the project schedule. The robust mechanical properties of the weld metal ensured the pipelines could safely operate under severe pressure and temperature fluctuations for their projected service life of 30+ years, showcasing the energy saving and durability advantages of a quality electrode 7016.

Case Study 2: Structural Repair of Heavy-Duty Mining Equipment

A mining company faced a critical issue with stress-induced cracking in the boom arm of a large excavator, constructed from high-tensile steel. Repairing such equipment quickly and reliably is essential to minimize costly operational downtime. The repair demanded an electrode that could provide high-strength, fatigue-resistant welds in challenging overhead and vertical positions, often under less-than-ideal field conditions.

- Challenge: Performing structural repairs on site, requiring an electrode with excellent all-positional weldability, robust mechanical properties, and minimal preheating requirements for large, thick sections of alloy steel.

- Solution: Our team recommended a specific batch of e7016 welding rods, known for their superior arc characteristics in out-of-position welding and their proven resistance to hydrogen cracking. We provided on-site technical guidance for optimal welding parameters.

- Outcome: The repair was completed efficiently, restoring the excavator's structural integrity. Post-repair inspections confirmed the absence of defects, and the equipment returned to service rapidly, demonstrating significant cost savings from reduced downtime and the extended service life of the repaired component. The superior crack resistance of the e7016 welding rod was critical to this success.

Ensuring Quality and Trust: Certifications & Partnerships

At the core of our operations is an unwavering commitment to quality and transparency, ensuring that our clients receive welding consumables that not only meet but exceed industry expectations. Our adherence to stringent international standards, combined with robust internal quality control measures, builds the foundation of trust with our global partners.

Authoritative Certifications & Compliance:

- ISO 9001:2015 Certified: Our quality management system is certified to ISO 9001, demonstrating our commitment to consistent product quality and customer satisfaction through effective processes and continuous improvement. This certification encompasses the entire lifecycle of our `Customized E7016 Welding Rods Electrodes`, from design and manufacturing to delivery and after-sales support.

- AWS A5.1/A5.1M Conformity: All our e7016 welding rods strictly conform to the American Welding Society (AWS) A5.1 specification, guaranteeing their chemical composition, mechanical properties, and operational characteristics meet the highest global benchmarks.

- CE Marking (EN ISO 2560): Our products bear the CE mark, indicating compliance with the essential health and safety requirements of European directives, and are manufactured in accordance with EN ISO 2560, enabling their seamless use across European markets.

- TÜV Rheinland Certified: Independent third-party validation by TÜV Rheinland further affirms the quality, safety, and reliability of our welding consumables, providing an additional layer of assurance for our clients.

- Years of Service: With over 20 years of dedicated service in the welding consumables industry, we bring a wealth of experience and metallurgical expertise to every product and solution we offer.

Trusted Partner Clients:

Our high-performance e7016 welding rods are trusted by leading companies in critical sectors worldwide. We partner with:

- Major petrochemical and oil & gas corporations

- Global heavy machinery manufacturers

- Infrastructure and construction contractors

- Shipbuilding and offshore engineering firms

- Power generation facilities

These partnerships are built on a foundation of proven product reliability, exceptional technical support, and a shared commitment to achieving superior welding outcomes. We continuously invest in research and development to stay at the forefront of welding technology, ensuring our electrode 7016 offerings remain the benchmark for quality and innovation.

Frequently Asked Questions (FAQ) about E7016 Welding Rods

Q1: What makes e7016 welding rods "low hydrogen"?

A1: The "low hydrogen" designation refers to the special flux coating of the electrode, which, after being subjected to high-temperature baking during manufacturing, contains minimal moisture. This significantly reduces the introduction of hydrogen into the weld metal, preventing hydrogen-induced cracking in sensitive materials like high-strength steels. Proper storage in dry conditions is crucial to maintain this low-hydrogen characteristic.

Q2: What types of metals can be welded with electrode 7016?

A2: E7016 welding rods are primarily designed for welding carbon steels and low-alloy steels, especially those with higher tensile strengths (e.g., A514, A517, API 5L grades). Their low-hydrogen properties are particularly beneficial for steels prone to cracking, and they are suitable for joining dissimilar metals within these categories.

Q3: What are the recommended storage conditions for e7016 welding rods?

A3: To maintain their low-hydrogen property, electrodes must be stored in dry, moisture-free conditions. Hermetically sealed container111s should be used for unopened packages. Once opened, electrodes should be stored in heated storage ovens (holding ovens) at temperatures typically between 100-150°C (212-300°F) to prevent moisture re-absorption. Any electrodes exposed to ambient humidity for extended periods should be re-baked according to manufacturer specifications.

Q4: What is the lead time for customized e7016 welding rods?

A4: Lead times for customized e7016 welding rod solutions vary depending on the complexity of the customization, order volume, and current production schedules. Typically, after detailed specification approval, production can range from 4 to 8 weeks, followed by standard shipping times. We work closely with clients to provide accurate lead time estimates for each specific order.

Q5: What warranty and after-sales support do you offer?

A5: We provide a comprehensive warranty against manufacturing defects, ensuring our `Customized E7016 Welding Rods Electrodes` meet all published specifications and industry standards. Our dedicated after-sales support team, comprised of experienced metallurgical engineers and welding experts, is available to assist with technical queries, application guidance, and troubleshooting to ensure optimal performance of our products in your operations. We are committed to long-term client satisfaction.

Conclusion: The Enduring Value of High-Performance E7016 Welding Rods

The persistent demand for robust and reliable welded structures across critical industrial sectors underscores the enduring importance of high-performance welding consumables. E7016 welding rods, with their unparalleled low-hydrogen properties and superior mechanical characteristics, represent a cornerstone of modern welding technology. From the meticulous selection of raw materials to the advanced manufacturing processes and stringent quality control, every stage in their production is geared towards delivering a product that ensures maximum structural integrity and operational longevity.

As industries continue to face complex challenges—from welding advanced high-strength steels to operating in extreme environmental conditions—the ability to procure consistently high-quality and, where necessary, customized electrode 7016 becomes a strategic advantage. By prioritizing certified manufacturers who demonstrate expertise, provide comprehensive support, and adhere to global quality benchmarks, businesses can safeguard their investments and ensure the reliability of their critical assets. Our commitment is to partner with you, offering not just electrodes, but a complete solution that embodies excellence, trust, and the highest standards of welding performance.

References

- American Welding Society. AWS A5.1/A5.1M:2012, Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

- International Organization for Standardization. ISO 2560:2020, Welding consumables — Covered electrodes for manual metal arc welding of non-alloy and fine grain steels — Classification.

- Japan Industrial Standards. JIS Z 3211:2010, Covered electrodes for manual arc welding of high tensile strength steels.

- The Welding Institute (TWI). "Hydrogen Cracking." TWI Global. Available at: www.twi-global.com/technical-knowledge/faqs/faq-what-is-hydrogen-cracking

- Welding Journal. "The Evolution of Low-Hydrogen Electrodes for Critical Applications." AWS Welding Journal, Vol. 98, No. 3, 2019.

-

What is a medium-frequency pulse? What types of welding are suitable for?VijestiNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?VijestiNov.21,2025

-

Welding Knowledge 6VijestiNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?VijestiNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?VijestiNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016VijestiNov.17,2025