febr . 10, 2025 09:53

Back to list

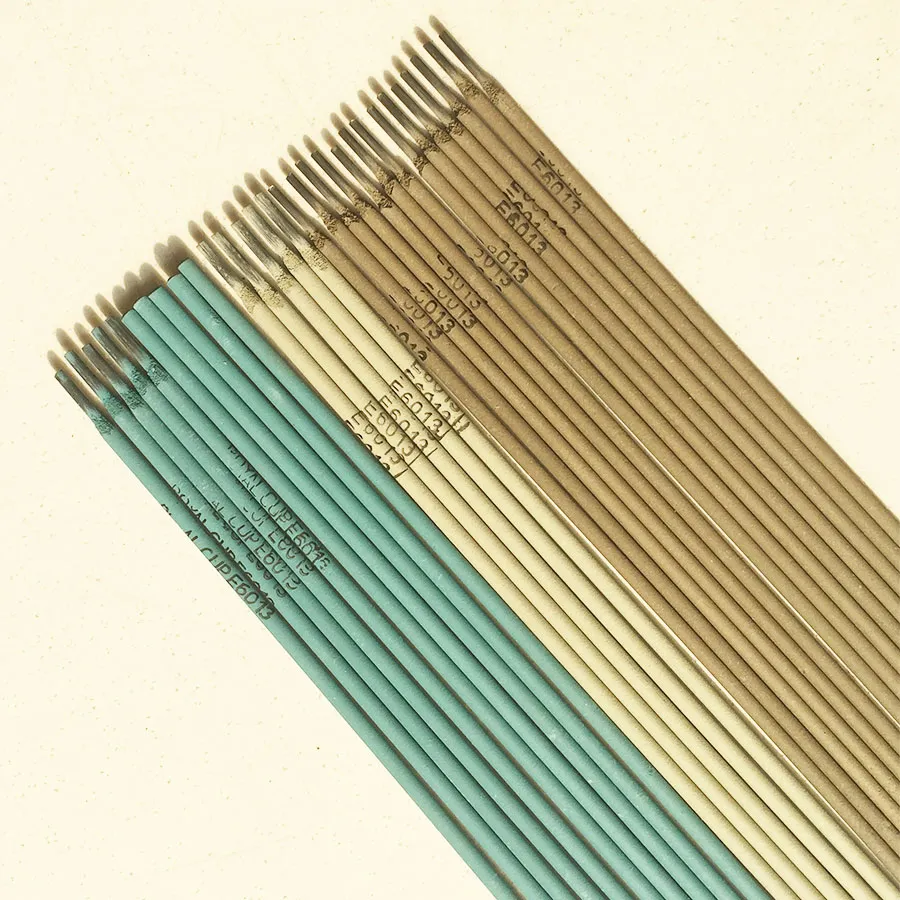

flux core welding wire 035

The welding sector is constantly evolving, with advancements in technologies and materials shaping the way professionals work. Among the foundational materials in this field is welding wire, particularly the ER70S-6 classification. For those delving into high-quality welding projects, understanding the specifics of 035 ER70S-6 welding wire can dramatically enhance results.

When it comes to authoritativeness, several industry standards and certifications back the use of ER70S-6 welding wires. It complies with standards from entities like the American Welding Society (AWS), ensuring the wire meets stringent quality criteria. This adherence to industry standards provides assurance to both novice and seasoned welders about the wire's integrity and performance under various conditions. Furthermore, trustworthiness in welding materials cannot be overstated. Manufacturers of 035 ER70S-6 ensure that their products undergo rigorous testing and quality control measures. Such diligence guarantees that each spool of wire will perform as expected. Welders, fabricators, and engineers often rely on testimonials and case studies that document the use of ER70S-6 across different projects, reinforcing its reputation as a reliable choice for quality MIG welding. In practice, achieving optimal results with 035 ER70S-6 involves understanding the settings and configurations that best suit specific applications. Typically, welders should adjust their machines to correspond with the wire's diameter, the type of shielding gas used (commonly a mix of Argon and CO2), and the base material thickness. Maintaining these parameters ensures maximum penetration and minimal bead defects. In conclusion, the 035 ER70S-6 welding wire stands out in the welding industry for its adaptability, precise compositional benefits, and the assurance of quality it provides to users. As industries continue to demand higher efficiency and productivity, utilizing reliable materials like ER70S-6 becomes a decisive factor in achieving superior weld quality. By incorporating this wire into your projects, you not only enhance the weld's strength and appearance but also align with industry standards that value excellence and reliability.

When it comes to authoritativeness, several industry standards and certifications back the use of ER70S-6 welding wires. It complies with standards from entities like the American Welding Society (AWS), ensuring the wire meets stringent quality criteria. This adherence to industry standards provides assurance to both novice and seasoned welders about the wire's integrity and performance under various conditions. Furthermore, trustworthiness in welding materials cannot be overstated. Manufacturers of 035 ER70S-6 ensure that their products undergo rigorous testing and quality control measures. Such diligence guarantees that each spool of wire will perform as expected. Welders, fabricators, and engineers often rely on testimonials and case studies that document the use of ER70S-6 across different projects, reinforcing its reputation as a reliable choice for quality MIG welding. In practice, achieving optimal results with 035 ER70S-6 involves understanding the settings and configurations that best suit specific applications. Typically, welders should adjust their machines to correspond with the wire's diameter, the type of shielding gas used (commonly a mix of Argon and CO2), and the base material thickness. Maintaining these parameters ensures maximum penetration and minimal bead defects. In conclusion, the 035 ER70S-6 welding wire stands out in the welding industry for its adaptability, precise compositional benefits, and the assurance of quality it provides to users. As industries continue to demand higher efficiency and productivity, utilizing reliable materials like ER70S-6 becomes a decisive factor in achieving superior weld quality. By incorporating this wire into your projects, you not only enhance the weld's strength and appearance but also align with industry standards that value excellence and reliability.

Previous:

Next:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025