Need e71t gs welding wire for clean, no-gas welds?

e71t gs welding wire,e71t gs flux core,e71t gs mig wire is a key solution in the manufacturing industry, specifically within Fabricated metal products and welding materials. This article explores how HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- e71t gs welding wire,e71t gs flux core,e71t gs mig wire Overview

- Benefits & Use Cases of e71t gs welding wire,e71t gs flux core,e71t gs mig wire in welding materials

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on e71t gs welding wire,e71t gs flux core,e71t gs mig wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

e71t gs welding wire,e71t gs flux core,e71t gs mig wire Overview

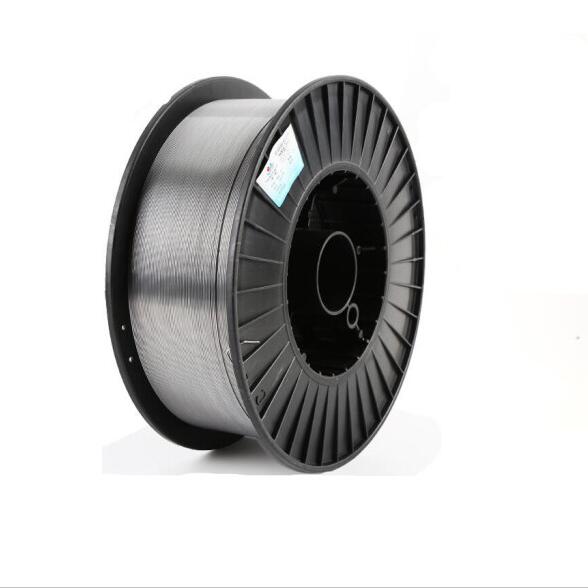

E71T-GS is a self-shielded flux-cored carbon steel wire designed for single-pass welding on thin-gauge mild and galvanized steels—ideal for shop floors and field repairs where productivity, portability, and clean appearance matter. Commonly called e71t gs welding wire or e71t gs mig wire, it runs on DCEN (straight polarity) and does not require external shielding gas, making it a proven choice for gasless MIG setups. Typical diameters include 0.8/0.9/1.2 mm (0.030/0.035/0.045 in), with all-position capability and tensile strength around 70 ksi, aligning with AWS A5.20 (E71T-GS).

As a manufacturer focused on the Fabricated metal products segment, HEBEI YUJINHONG TECHNOLOGY CO.,LTD. delivers e71t gs flux core solutions with tight diameter control, stable arc characteristics, and low spatter for reduced rework. Spool options and packaging are engineered for consistent feedability and minimal downtime. In a sheet-metal fabrication scenario, E71T-GS has been used to quickly close lap joints on 1.2–2.5 mm galvanized sheet, producing smooth beads with fast-freezing slag and strong, aesthetically clean outcomes—without the complexity of cylinders, regulators, and gas logistics.

Benefits & Use Cases of e71t gs welding wire,e71t gs flux core,e71t gs mig wire in welding materials

In welding materials for the Fabricated metal products sector, e71t gs flux core stands out for speed, simplicity, and portability. Because e71t gs mig wire is self-shielded, teams can set up quickly and weld indoors or outdoors without gas bottles—perfect for maintenance, light fabrication, shop fit-outs, onsite installations, ducting, farm equipment repairs, HVAC brackets, and galvanized sheet assemblies. The wire’s fast-freeze slag helps control heat input on thin material, limiting burn-through and distortion while maintaining a neat bead profile.

Key advantages include all-position performance, stable arc starts, and low spatter that reduces cleanup. Compared with solid wire + gas, e71t gs welding wire lowers equipment complexity, simplifies training, and cuts consumable logistics. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. brings category expertise with consistent spool winding, dependable wire stiffness for smooth feeding, and process guidance tailored to B2B requirements. While E71T-GS is optimized for single-pass welds on thin gauge, it is a high-productivity answer for everyday fabrication tasks where agility, uptime, and cost control drive competitive advantage.

Cost, Maintenance & User Experience

Total cost of ownership improves with e71t gs welding wire because you eliminate shielding gas purchases, cylinder rentals, and handling time. For many B2B buyers, this translates into lower capex and opex on ancillary equipment, fewer points of failure, and faster operator onboarding. The wire’s low spatter characteristics reduce post-weld grinding, saving labor. When paired with correct parameters (e.g., DCEN, appropriate voltage and wire feed for the diameter and sheet thickness), the result is reliable fusion and clean bead geometry—less rework and higher throughput.

Maintenance is straightforward: keep e71t gs flux core spools dry, avoid contamination, and store in original packaging when not in use. Check liners and contact tips for wear to preserve feedability. Fabricated metal products customers report shorter setup times and more consistent results on light-gauge jobs, especially galvanized components, compared with gas-shielded processes. Many operations note improved ROI within months due to portability, quick changeovers, and fewer consumable variables. For teams migrating from stick or solid-wire MIG, e71t gs mig wire offers a smooth learning curve and immediate productivity gains in single-pass applications.

Sustainability & Market Trends in manufacturing

Manufacturing leaders are prioritizing lean, flexible welding cells that reduce energy, consumables, and logistical overhead. E71T-GS supports this shift by eliminating gas cylinders and associated transport, which can lower the carbon footprint of supply chains and simplify EHS management. At the same time, the growing use of galvanized thin sheet in construction fittings, HVAC, and light fabrications aligns with the strengths of e71t gs welding wire—controlled heat input and clean finishes in single-pass workflows.

Regulatory and customer demands for traceability and consistent quality continue to tighten. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. operates with rigorous quality controls aligned to international standards, focusing on stable chemistry, reliable mechanical properties, and repeatable performance lot-to-lot. The company is investing in process optimization and responsible packaging to minimize waste and support circularity. For B2B decision makers, partnering with a forward-thinking supplier ensures not only dependable e71t gs flux core availability, but also ongoing technical support as market requirements evolve.

Conclusion on e71t gs welding wire,e71t gs flux core,e71t gs mig wire from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

E71T-GS is a practical, high-uptime consumable for thin-gauge single-pass welding across the Fabricated metal products landscape. By combining portability, simplicity, and clean bead quality, e71t gs mig wire helps shops and field crews cut setup time and rework while maintaining consistent results. With HEBEI YUJINHONG TECHNOLOGY CO.,LTD., buyers gain a dependable source for e71t gs welding wire that is engineered for productivity and backed by expert support.

Contact us: info@steeltoolschina.com

Visit our website: https://www.steeltoolschina.com

-

What is a medium-frequency pulse? What types of welding are suitable for?BeritaNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?BeritaNov.21,2025

-

Welding Knowledge 6BeritaNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?BeritaNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?BeritaNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016BeritaNov.17,2025