Jan . 20, 2025 05:53

Back to list

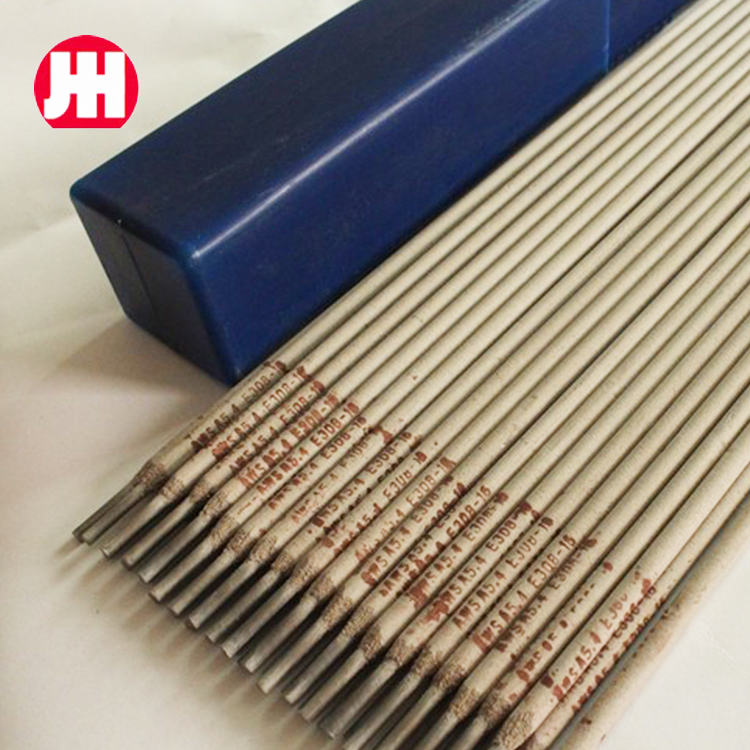

rutile welding rod

Rutile welding rods remain a cornerstone in the welding industry, appreciated for their unique properties and widespread application. A comprehension of the experience, expertise, authoritativeness, and trustworthiness associated with these rods helps in understanding their prominence.

Contributing to their authoritativeness in the welding domain is the scientific endorsement of their characteristics. The moderate penetration capabilities of rutile electrodes ensure a secure and durable weld that holds up under stress testing and real-world conditions. These properties have been corroborated by technical assessments and material science studies, reinforcing the rods' reputation as reliable. Furthermore, professionals often cite their compatibility with AC or DC power sources, providing flexibility and making them a viable option for a myriad of welding machines. This adaptability underscores their authoritative position in welding supplies. Rutile welding rods’ trustworthiness is deeply ingrained due to their consistent results. Customers and industries value products that deliver predictable and stable outcomes, which these rods consistently achieve. The controlled arc and the straightforwardness of use minimize defects, enhancing welder confidence and subsequently, trust. Moreover, standards and certifications from international welding organizations verify the rods' quality and safety, providing an added layer of trustworthiness that industry professionals rely on. Such certifications not only validate user experiences but also maintain a benchmark for future innovations and improvements. Comprehending rutile welding rods in terms of product-focused criteria such as experience, expertise, authoritativeness, and trustworthiness allows a deeper understanding of their value in practical applications. Their ability to offer ease of use, cross-industry applicability, scientific validation, and reliable performance cements their standing as indispensable tools in the arsenal of welding supplies. As technology continues to progress, the evolution and refinement of rutile rods will likely enhance their core benefits, ensuring that they remain an essential component in quality welding outcomes for years to come.

Contributing to their authoritativeness in the welding domain is the scientific endorsement of their characteristics. The moderate penetration capabilities of rutile electrodes ensure a secure and durable weld that holds up under stress testing and real-world conditions. These properties have been corroborated by technical assessments and material science studies, reinforcing the rods' reputation as reliable. Furthermore, professionals often cite their compatibility with AC or DC power sources, providing flexibility and making them a viable option for a myriad of welding machines. This adaptability underscores their authoritative position in welding supplies. Rutile welding rods’ trustworthiness is deeply ingrained due to their consistent results. Customers and industries value products that deliver predictable and stable outcomes, which these rods consistently achieve. The controlled arc and the straightforwardness of use minimize defects, enhancing welder confidence and subsequently, trust. Moreover, standards and certifications from international welding organizations verify the rods' quality and safety, providing an added layer of trustworthiness that industry professionals rely on. Such certifications not only validate user experiences but also maintain a benchmark for future innovations and improvements. Comprehending rutile welding rods in terms of product-focused criteria such as experience, expertise, authoritativeness, and trustworthiness allows a deeper understanding of their value in practical applications. Their ability to offer ease of use, cross-industry applicability, scientific validation, and reliable performance cements their standing as indispensable tools in the arsenal of welding supplies. As technology continues to progress, the evolution and refinement of rutile rods will likely enhance their core benefits, ensuring that they remain an essential component in quality welding outcomes for years to come.

Previous:

Next:

Latest news

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025