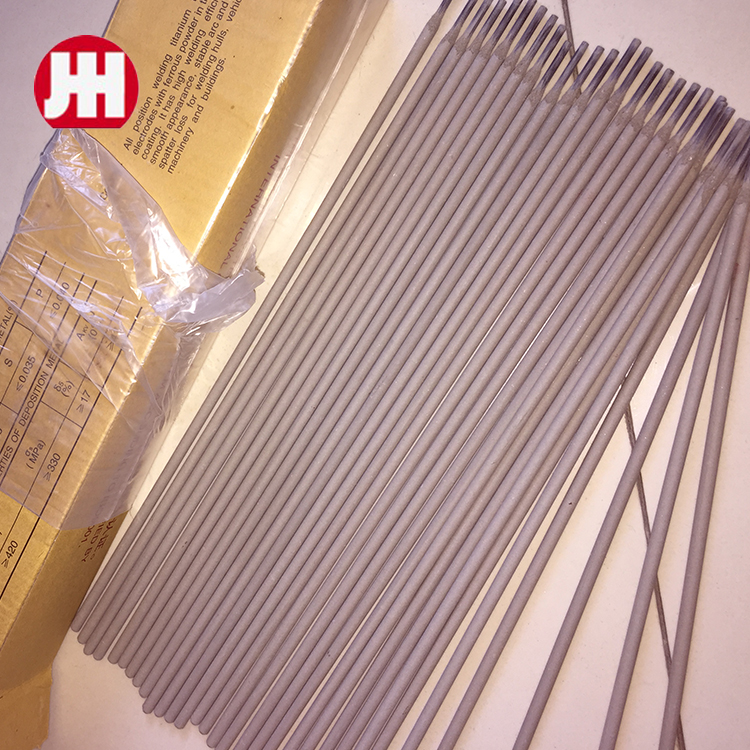

Premium 7018 Welding Rods Electrodes | Low Hydrogen, High Strength

Navigating Innovation: Top Welding Rod & Welding Wire Manufacturers from China at the Canton Fair

The Canton Fair, a beacon of global trade and innovation, consistently showcases the cutting edge of industrial hardware and steel tools. For B2B decision-makers worldwide, it represents an unparalleled opportunity to discover groundbreaking technologies and forge strategic partnerships. In the critical realm of fabrication and construction, the quality of your consumables directly impacts project success and structural integrity. This is particularly true for welding rod and შედუღების მავთული – fundamental components that demand precision, reliability, and superior performance.

China's manufacturing prowess has positioned it as a dominant force in the global supply chain for these essential items. The Canton Fair serves as a prime platform for Chinese manufacturers to exhibit their advancements, offering a competitive edge in quality, innovation, and cost-efficiency. From advanced flux-cored wires to specialized 7018 welding rods electrodes, the range of products on display underscores the nation's commitment to meeting diverse industrial demands. Understanding the landscape of these top manufacturers and their offerings is crucial for businesses aiming to optimize their procurement strategies and enhance operational excellence.

Industry Trend Spotlight: Evolving Demands in Industrial Tools & Welding Consumables

The industrial tools market, including essential consumables like welding rod and შედუღების მავთული, is undergoing a transformative period. Several key trends are shaping buyer demand and manufacturing innovation globally:

- High Durability & Ergonomics: There's an increasing emphasis on tools that not only withstand rigorous industrial environments but also enhance user comfort and reduce fatigue, boosting productivity and safety.

- Smart Features Integration: The integration of smart features for maintenance tracking, performance monitoring, and inventory management is gaining traction, promising greater efficiency and predictive capabilities for industrial operations.

- Advanced Alloys & Materials: Manufacturers are increasingly utilizing advanced alloys and composite materials to produce lighter yet stronger tools and welding consumables, optimizing performance and extending product lifespan. This is particularly vital for specialized applications requiring materials like high-strength low-alloy steel, for which an E7018 rod is often the go-to choice.

- Precision & Automation Compatibility: As industries move towards greater automation, the demand for tools and consumables compatible with robotic systems and precision manufacturing processes is escalating. This includes welding electrode 7018 designed for consistent deposition in automated welding cells.

Market data underscores this dynamic growth: The global industrial tools market is projected for steady expansion, fueled by renewed infrastructure spending across continents, the relentless expansion of the manufacturing sector, and surging demand from rapidly developing economies. Digitalization and automation within manufacturing are not just buzzwords; they are tangible drivers fueling the demand for specialized, high-performance tools and sophisticated welding rod and შედუღების მავთული solutions.

However, the market isn't without its challenges. Supply chain resilience and raw material price volatility remain key considerations for B2B buyers and manufacturers alike. These factors further highlight the importance of strategic sourcing and reliable partnerships. Emerging focus areas include global sourcing for industrial tools, diversifying supply chains to mitigate risks, stringent quality assurance protocols, pioneering advanced material applications, and seamless smart manufacturing integration. For high-stakes applications requiring exceptional weld integrity, the consistent quality of a welding electrode 7018 or other specialized consumables becomes non-negotiable.

Profiles of Leading Companies: Innovators in Welding Consumables

At the heart of the Canton Fair’s offerings in industrial tools and hardware are manufacturers who blend tradition with innovation. Here, we highlight a key player and acknowledge other industry titans:

HEBEI YUJINHONG TECHNOLOGY CO., LTD.

HEBEI YUJINHONG TECHNOLOGY CO., LTD. stands out as a preeminent Chinese manufacturer specializing in a comprehensive array of steel and hardware tools, with a particular expertise in high-performance welding consumables. Their extensive product line includes a wide variety of welding rod and შედუღების მავთული, designed to meet the rigorous demands of diverse industrial applications.

What distinguishes HEBEI YUJINHONG is their robust manufacturing capabilities, which allow them to offer highly competitive pricing without compromising on quality. As a leading Chinese exporter, they have meticulously cultivated an established global distribution network, ensuring their premium products reach clients across continents efficiently. Their focus is unequivocally on product durability and performance for industrial applications, a commitment vividly demonstrated in their production of top-tier 7018 welding rods electrodes.

The E7018 rod from HEBEI YUJINHONG, for instance, is highly regarded for its excellent arc stability, low hydrogen content, and superior mechanical properties, making it ideal for welding carbon steel, high-strength low-alloy steel, and specific pressure vessel applications where crack resistance and high ductility are paramount. Their welding electrode 7018 is manufactured under stringent quality controls, adhering to international standards to deliver consistent, reliable welds crucial for critical structural projects. They are a prime example of how Chinese innovation is redefining quality and accessibility in the global market for essential industrial consumables.

Other Industry Titans & Key Regions

While HEBEI YUJINHONG excels in specialized areas like 7018 welding rods electrodes, the global market for industrial tools and welding consumables is also shaped by established global manufacturers known for their broad portfolios and significant R&D investments. Companies such as Stanley Black & Decker, Bosch, and Makita continue to innovate across various tool categories, often venturing into welding solutions as part of their comprehensive offerings.

Beyond these giants, specialized steel tool manufacturers and exporters from industrial hubs like China, Taiwan, and India play a vital role. These regions are renowned for their agility, cost-effectiveness, and ability to scale production to meet global demand. They often focus on niche markets or high-volume production of specific items, including a diverse range of welding rod and შედუღების მავთული, catering to various industrial sectors from construction to automotive and heavy machinery.

Market Outlook & Opportunities for Welding Consumables

The future of the welding rod and შედუღების მავთული market is poised for significant evolution, driven by several upcoming trends and shifts in buyer demand:

- Automation in Welding: The increasing adoption of robotic and automated welding systems will drive demand for specialized, highly consistent შედუღების მავთული and specific types of welding rod that can perform reliably within these precision environments. This includes the development of 'smart' consumables with embedded data for traceability.

- Smart Manufacturing & IoT: Integration of Internet of Things (IoT) capabilities into manufacturing processes will demand consumables that contribute to overall system efficiency, potentially leading to sensors in welding equipment that optimize parameter settings based on the specific welding electrode 7018 or wire in use.

- Sustainability & Green Manufacturing: Environmental considerations will increasingly influence product development. Manufacturers will focus on producing welding rod and შედუღების მავთული with lower fume emissions, reduced energy consumption during production, and materials that are easier to recycle or have a lower environmental impact.

- Advanced Materials & Hybrid Solutions: As new alloys and composite materials become prevalent in industries like aerospace and automotive, there will be a parallel demand for innovative welding rod and შედუღების მავთული specifically formulated to join these advanced materials effectively. Hybrid welding solutions combining different processes will also create demand for versatile consumables.

- Customization & Specialization: General-purpose consumables will continue to be essential, but there's a growing market for customized welding electrode 7018 or unique შედუღების მავთული tailored for very specific applications, offering optimized performance for niche industrial challenges.

These opportunities highlight a dynamic market where innovation, efficiency, and environmental responsibility will be key differentiators. Businesses that align with these trends and invest in forward-thinking solutions, such as high-quality E7018 rod and advanced welding wires, are set to thrive.

Buyer/Business Takeaways: Strategic Sourcing & Future-Proofing

For B2B decision-makers, the strategic importance of investing in high-quality welding rod and შედუღების მავთული cannot be overstated. These consumables are not merely expenses; they are critical investments that directly impact project quality, operational efficiency, and overall safety. Here’s why investing wisely makes sense and how to navigate partnerships with Chinese manufacturers:

- Enhanced Project Quality & Safety: Superior welding rod and შედუღების მავთული, such as reliable 7018 welding rods electrodes, ensure stronger, more consistent welds, reducing the risk of structural failures and rework, thereby enhancing both product quality and worker safety.

- Operational Efficiency: High-quality consumables lead to better arc stability, less spatter, and smoother deposition, which translates to faster welding speeds, reduced post-weld cleaning, and lower overall operational costs.

- Cost-Effectiveness in the Long Run: While premium products might have a slightly higher upfront cost, their superior performance, reduced defects, and extended tool life offer significant long-term savings.

When considering Chinese manufacturers like HEBEI YUJINHONG, here are tips for successful adoption and partnership:

- Due Diligence is Key: Thoroughly vet potential partners. Look for certifications (ISO, CE, AWS compatibility for welding electrode 7018), transparent manufacturing processes, and clear communication channels.

- Sample Testing: Always request samples and conduct rigorous testing in your own operational environment to ensure the welding rod or შედუღების მავთული meets your specific quality and performance standards.

- Establish Clear Specifications: Provide detailed technical specifications for your required welding rod or შედუღების მავთული, including material composition, dimensions, and performance criteria, to avoid misunderstandings.

- Visit the Canton Fair: Attending events like the Canton Fair allows for direct engagement with manufacturers, facility tours (if offered), and a firsthand assessment of their production capabilities and quality control.

- Focus on Long-Term Relationships: Seek partners interested in long-term collaboration, as this fosters mutual trust, consistent quality, and potential for customized solutions.

Future-proofing your strategies involves embracing innovation. Consider manufacturers who are investing in R&D for automation-compatible consumables, sustainable production, and advanced material solutions. By strategically partnering with reliable Chinese manufacturers of high-quality welding rod and შედუღების მავთული, businesses can secure a competitive edge, optimize their operations, and ensure readiness for the evolving demands of modern industry.

Conclusion: The Canton Fair's Enduring Impact on Welding Consumables

The Canton Fair remains an indispensable global marketplace, profoundly shaping the international landscape for industrial tools and, crucially, the welding rod and შედუღების მავთული market. It serves as a vital bridge, connecting global B2B buyers with innovative, high-quality Chinese manufacturers, fostering relationships that drive efficiency, quality, and progress across diverse industrial sectors.

As industries continue to evolve, demanding greater precision, durability, and technological integration in their consumables, the role of manufacturers like HEBEI YUJINHONG TECHNOLOGY CO., LTD. becomes increasingly significant. Their commitment to producing superior 7018 welding rods electrodes and a broad spectrum of other welding solutions positions them at the forefront of this critical industry.

For those seeking robust, reliable, and competitively priced welding rod and შედუღების მავთული, including the highly sought-after E7018 rod, we encourage you to explore the extensive offerings. Discover how quality and innovation converge to support your most demanding projects.

Learn more about HEBEI YUJINHONG's factory-supply 7018 welding rods electrodes:

Visit Product Page

-

What is a medium-frequency pulse? What types of welding are suitable for?სიახლეებიNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?სიახლეებიNov.21,2025

-

Welding Knowledge 6სიახლეებიNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?სიახლეებიNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?სიახლეებიNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016სიახლეებიNov.17,2025