Superior Flux Core Wire for Gasless Welding | Easy & Strong

Unlocking Global Opportunities: Top Welding Rod & Welding Wire Manufacturers at the Canton Fair

For B2B decision-makers worldwide, the Canton Fair stands as an unrivaled beacon, a global marketplace where innovation meets opportunity. Each edition showcases an unparalleled array of high-quality steel tools and industrial hardware, drawing thousands of astute buyers seeking the next competitive edge. Within this vibrant ecosystem, the welding rod and შედუღების მავთული industry finds a crucial platform, connecting leading manufacturers with a diverse international clientele.

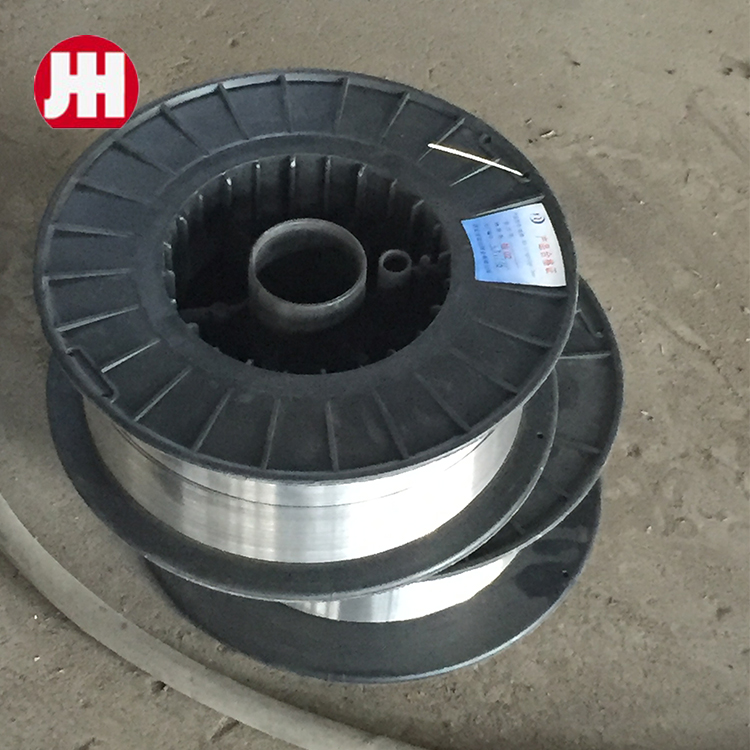

As global manufacturing evolves, the demand for advanced welding consumables – particularly specialized solutions like flux core wire and aluminum flux core wire – continues to surge. The Canton Fair is where these critical innovations are brought to the forefront, offering buyers direct access to the latest technologies, competitive pricing, and robust supply chain partners essential for modern industrial operations. It’s an indispensable event for anyone looking to source high-performance welding materials that promise durability, efficiency, and superior weld quality.

Industry Trend Spotlight: Navigating the Evolving Landscape of Industrial Tools

The industrial tools sector is undergoing a profound transformation, driven by a confluence of technological advancements and shifting market demands. Today's buyers are increasingly prioritizing:

- High-Durability & Ergonomics: Tools designed for extended operational life and enhanced user comfort, reducing fatigue and improving productivity in demanding environments. For welding, this means rods and wires that offer consistent performance under various conditions, minimizing downtime and rework.

- Integration of Smart Features: From embedded sensors for predictive maintenance to digital tracking for inventory management, smart capabilities are enhancing operational efficiency. While less direct for consumables, the trend extends to packaging and identification systems for welding materials.

- Advanced Alloys for Lighter, Stronger Tools: The quest for materials that offer superior strength-to-weight ratios continues, enabling more efficient and powerful tools. In welding, this translates to specialized flux core wire and aluminum flux core wire formulations that deliver exceptional mechanical properties for critical applications in automotive, aerospace, and construction.

- Precision and Automation Compatibility: The rise of robotics and automated manufacturing lines necessitates tools and consumables that ensure unparalleled precision and seamless integration. High-quality შედუღების მავთული and welding rod are foundational to achieving consistent, repeatable welds in automated systems.

Market data underscores these shifts: The global industrial tools market is projected for steady growth, buoyed by renewed infrastructure spending across continents, robust expansion in the manufacturing sector, and increasing demand from developing economies. Digitalization and automation in manufacturing are also fueling demand for highly specialized tools and consumables that can meet the rigorous requirements of modern production lines.

However, challenges persist. Supply chain resilience has become a paramount concern, especially given recent global disruptions, while raw material price volatility continues to be a key consideration for manufacturers and buyers alike. In response, emerging focus areas for B2B decision-makers include global sourcing for industrial tools, diversification of supply chains, stringent quality assurance protocols, the application of advanced materials, and seamless smart manufacturing integration.

Profiles of Leading Manufacturers: Innovation at the Core

HEBEI YUJINHONG TECHNOLOGY CO., LTD.

A prominent name at the forefront of China's industrial hardware sector, HEBEI YUJINHONG TECHNOLOGY CO., LTD. stands as an exemplary Chinese exporter. Specializing in a wide range of steel and hardware tools, their offerings are meticulously engineered to meet the stringent demands of modern industrial applications. A particular strength lies in their comprehensive portfolio of welding rod and შედუღების მავთული, including advanced flux core wire and innovative aluminum flux core wire solutions.

What sets HEBEI YUJINHONG TECHNOLOGY apart is their robust manufacturing capabilities, which allow them to offer highly competitive pricing without compromising on quality. This, coupled with an established global distribution network, makes them a reliable partner for businesses seeking consistent supply and technical excellence. Their unwavering focus on product durability and superior performance ensures that their welding consumables deliver optimal results, enhancing efficiency and weld integrity across diverse projects.

Explore HEBEI YUJINHONG TECHNOLOGY's Flux Core Wire Solutions

The Broader Landscape: Global & Regional Leaders

Beyond specialized Chinese exporters like HEBEI YUJINHONG TECHNOLOGY, the global welding rod and შედუღების მავთული market is also shaped by established global tool manufacturers such as Stanley Black & Decker, Bosch, and Makita, who offer comprehensive industrial solutions. Additionally, numerous specialized steel tool manufacturers and exporters from industrial hubs like China, Taiwan, and India continually push the boundaries of material science and manufacturing efficiency. These regions are particularly vital for sourcing a diverse range of welding consumables, from general-purpose electrodes to highly specific flux core wire and aluminum flux core wire designed for niche applications. Their collective presence at events like the Canton Fair highlights the dynamic and competitive nature of the global market.

Market Outlook & Opportunities: Charting the Future of Welding Consumables

The future of the welding rod and შედუღების მავთული market is characterized by several key trends and evolving buyer demands. Buyers are increasingly seeking:

- Higher Deposition Rates and Lower Spatter: To maximize productivity and minimize post-welding cleanup.

- Specialized Alloys: For joining exotic materials and addressing specific industry challenges in sectors like oil & gas, aerospace, and power generation. This includes advanced aluminum flux core wire for lightweight structures.

- Environmental Considerations: Demand for welding consumables with reduced fume emissions and sustainable manufacturing processes.

- Consistency and Traceability: Ensuring batch-to-batch consistency and full traceability for quality control and regulatory compliance, particularly critical for flux core wire used in high-stakes applications.

Significant opportunities lie in:

- Automation: The increasing adoption of robotic welding systems makes high-quality flux core wire and aluminum flux core wire indispensable. These consumables are engineered for consistent feeding, arc stability, and repeatable performance, which are critical for automated processes to achieve high efficiency and minimal defects.

- Smart Manufacturing: Integration with IoT and data analytics for predictive maintenance of welding equipment and optimizing consumable usage. This offers a path to smarter, more proactive inventory management and operational control.

- Sustainability: The drive towards greener manufacturing processes presents opportunities for welding consumables that reduce waste, consume less energy, and contribute to a smaller environmental footprint.

Buyer/Business Takeaways: Strategic Sourcing for the Future

For B2B decision-makers, investing in high-quality welding rod and შედუღების მავთული, especially advanced flux core wire and aluminum flux core wire solutions from reputable Chinese manufacturers like HEBEI YUJINHONG TECHNOLOGY, is a strategic imperative. Here’s why and how to approach it:

- Compelling Value Proposition: Chinese manufacturers offer an attractive blend of cost-efficiency, access to cutting-edge technology, and scalability. Their ability to produce at high volumes ensures competitive pricing without sacrificing the quality required for industrial applications.

- Leveraging Innovation: Many Chinese manufacturers are at the forefront of R&D in welding consumables, particularly in specialized areas like flux core wire formulations for specific alloys and aluminum flux core wire for lightweight construction, offering access to superior product performance.

- Strategic Partnerships: Partnering with experienced Chinese exporters can provide a stable and diversified supply chain, mitigating risks associated with single-source reliance and geopolitical shifts.

Tips for Successful Adoption and Partnership:

- Thorough Due Diligence: Vet potential partners comprehensively, focusing on certifications, production capabilities, quality control processes, and existing client testimonials.

- Clear Communication: Establish precise specifications and communication channels from the outset to avoid misunderstandings and ensure products meet exact requirements.

- Quality Control: Implement robust third-party inspection and quality assurance measures, especially for critical welding consumables, to maintain consistent performance.

- Logistics & Compliance: Understand shipping logistics, import regulations, and local compliance standards to ensure smooth delivery and market entry.

Future-Proof Strategies:

- Diversify Your Supply Chain: Do not put all your eggs in one basket. Having multiple trusted suppliers, including those from China, enhances resilience.

- Embrace Technological Upgrades: Continuously evaluate new welding rod and შედუღების მავთული technologies that offer performance improvements, such as advanced flux core wire for specific applications.

- Focus on Total Cost of Ownership (TCO): Beyond unit price, consider the long-term benefits of quality, reliability, and reduced operational costs that high-performance consumables bring.

Conclusion: Your Gateway to Welding Excellence

The Canton Fair serves as an indispensable compass, guiding global B2B decision-makers through the dynamic landscape of industrial hardware. Its consistent showcase of top Chinese manufacturers, particularly in the critical welding rod and შედუღების მავთული sector, significantly shapes the global market. With companies like HEBEI YUJINHONG TECHNOLOGY CO.,LTD. leading the charge in developing advanced flux core wire and aluminum flux core wire, the opportunities for innovation, efficiency, and strategic sourcing are immense.

By engaging with these industry leaders, B2B buyers can secure not just high-quality products, but also reliable partnerships that are essential for navigating the complexities of modern manufacturing and achieving long-term success.

-

What is a medium-frequency pulse? What types of welding are suitable for?სიახლეებიNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?სიახლეებიNov.21,2025

-

Welding Knowledge 6სიახლეებიNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?სიახლეებიNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?სიახლეებიNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016სიახლეებიNov.17,2025